Organic waste water processing method with synchronously carbon, nitrogen and sulfur removal in one reactor

A technology for organic wastewater treatment and organic wastewater, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low treatment efficiency, high operating cost, complex process, etc. Achieve high processing efficiency and save floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

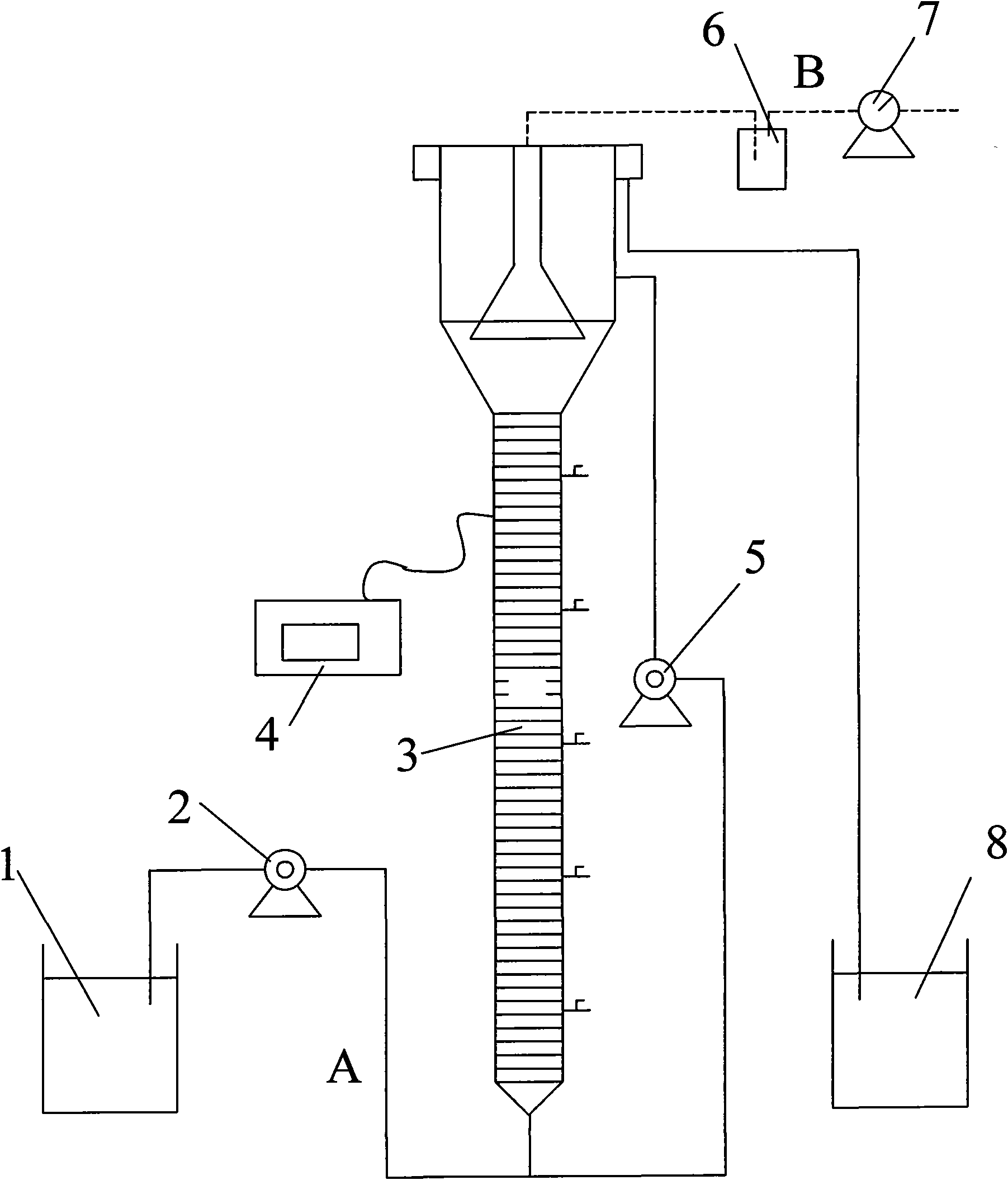

[0016] Specific implementation mode one: see figure 1 , the organic wastewater treatment method for synchronous removal of carbon, nitrogen and sulfur in a reactor described in this embodiment comprises the following steps:

[0017] Step 1, using only one fluidized bed reactor 3 organic wastewater carbon, nitrogen and sulfur synchronous removal integrated equipment to treat wastewater; the wastewater (wastewater to be treated) is mainly polluted by sulfate, nitrate and organic matter Sulfur-nitrogen-containing organic wastewater with a mass ratio of sulfur to nitrogen of 0.5-5 and a mass ratio of COD to N of 3-8;

[0018] Step 2. Cultivate granular sludge: First, add activated sludge into the fluidized bed reactor 3; then, introduce the waste water to be treated into the fluidized bed reactor 3, and the volume load of the influent in N shall not exceed 2.0kgN / m 3 d, keep the temperature in the fluidized bed reactor 3 at 20-35°C, the hydraulic retention time (HRT) 4h-16h, an...

specific Embodiment approach 2

[0022] Specific embodiment two: In step one of this embodiment, the sulfur-nitrogen mass ratio is 2-2.5, and the sulfur-nitrogen-containing organic wastewater with a COD and N mass ratio of 3-8, wherein the sulfur-nitrogen mass ratio is 2.5, COD to N mass ratio is 5.0, nitrate volume load is 1.5kgN / m 3 When d, the removal effect is the best, and the removal rate of sulfate, nitrate and organic matter reaches 98%, 98% and 80% respectively. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation method three: In step two of this embodiment, the trace element solution contains 500 mg of H per liter. 3 BO 3 , 500mg of ZnCl 2 , 500mg of (NH 4 ) 6 Mo 7 o 24 4H 2 O, 500mg of NiCl·6H 2 O, 500mg of AlCl 3 ·6H 2 O, 500mg of CoCl 2 ·6H 2 O, 500mg of CuSO 4 ·5H 2 O, 1000mg of NaSeO 3 ·5H 2 O, 1500mg of FeCl 3 ·6H 2 O, 5000mg of MnCl 2 4H 2 O and 5 ml of a 37% HCl solution. The addition of trace elements can promote and strengthen the formation of granular sludge, shortening the formation time of granular sludge by half a month. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com