Electric pumping random laser of silicon zinc oxide nano-rod array

A zinc oxide nanorod, random laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problem of difficulty in increasing, and achieve the effect of reducing threshold voltage, mature preparation process, and enhancing light scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

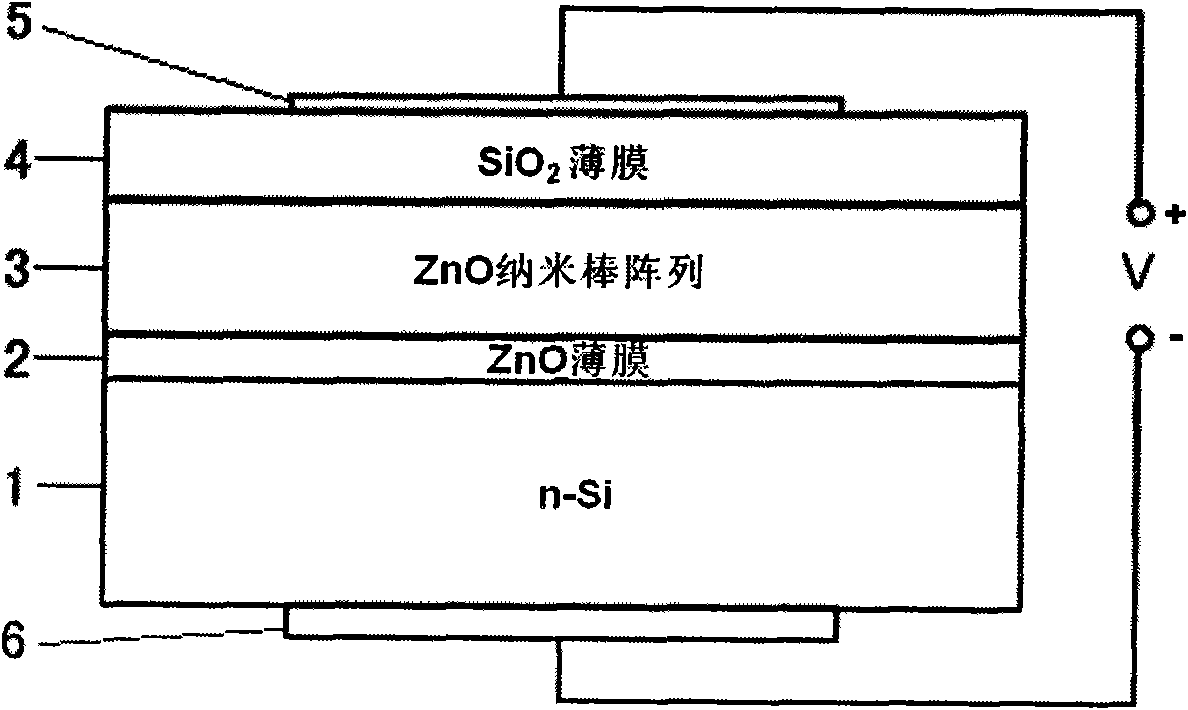

[0028] Such as figure 1 As shown, a silicon-based zinc oxide nanorod array electrically pumped random laser, on the front side of a silicon substrate 1, ZnO film 2, ZnO nanorod array 3, SiO 2 The thin film 4 and the translucent electrode 5 are deposited with an ohmic contact electrode 6 on the back of the silicon substrate.

[0029] Take the following process steps to prepare figure 1 The electrically pumped random laser shown:

[0030] 1) Clean n-type, resistivity 0.005 ohm cm, size 15×15mm 2 , a silicon chip with a thickness of 525 microns, and then put it into the cavity of a magnetron sputtering device, using a Zn sheet with a purity of 99.99% as the target, and the distance between the target and the substrate is 7cm; Draw to 5×10 -3 Below Pa, then pass high-purity Ar and O 2 gas, O 2 The flow ratio of Ar and Ar is 1:2, and the working pressure in the chamber is controlled to 10Pa; during sputtering, the power is about 120W, the deposition temperature is 300°C; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com