One-dimensional zinc oxide nanometer material and preparation method thereof

A technology of zinc oxide nanometer and sodium hydroxide, applied in nanostructure manufacturing, zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of cumbersome pretreatment, long reaction time, high reaction temperature, etc. Easy-to-obtain, easy-to-follow effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A. ZnCl 2 Prepare a zinc salt solution with a concentration of 0.4 mol / L with deionized water, and take 20 ml and place it in a stirred reactor.

[0030] B. NaOH is prepared into a NaOH solution with a concentration of 2.0 mol / L with deionized water.

[0031] C. Under stirring, the NaOH solution is slowly added dropwise to the zinc salt solution until the molar ratio of zinc ions and hydroxide ions in the mixed solution is 1:7. After stirring for 15 minutes, add an appropriate amount of hexadecyltrimethylammonium bromide at a concentration of 3g per liter, stir and dissolve to obtain a reaction solution; seal the reactor, react at a temperature of 80°C for 5 hours, and cool to room temperature naturally. The product is filtered, washed with deionized water for 3 to 5 times, then washed with absolute ethanol for 3 to 5 times, and then dried naturally to obtain a one-dimensional zinc oxide nanometer material with good crystallinity.

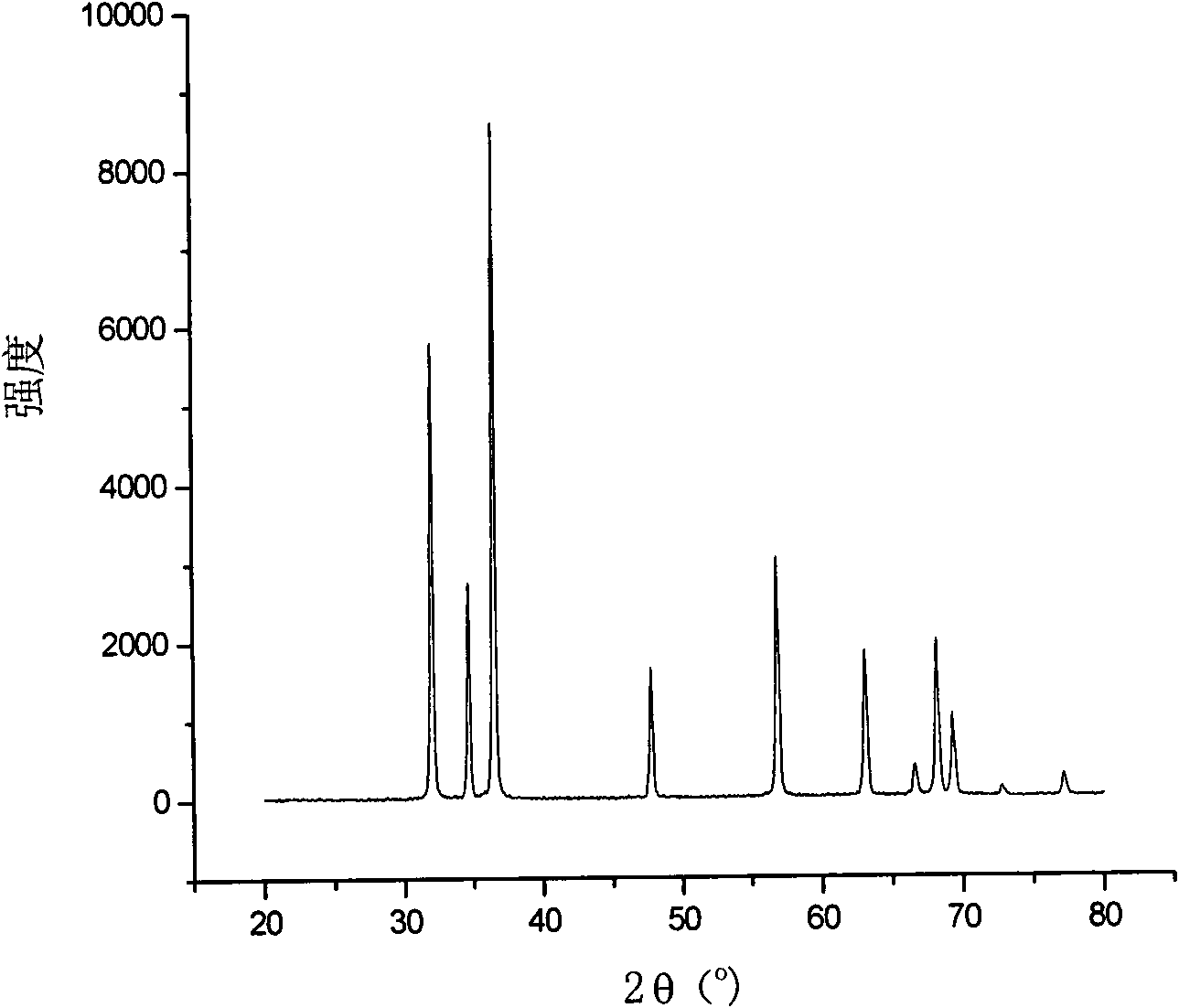

[0032] The results of X-ray diffrac...

Embodiment 2

[0034] A. Adding Zn(NO 3 ) 2 Prepare a zinc salt solution with a concentration of 0.2 mol / L with deionized water, and take 20 ml and place it in a stirred reactor.

[0035] B. NaOH is prepared into a NaOH solution with a concentration of 1.0 mol / L with deionized water.

[0036] C. Under stirring, the NaOH solution is slowly added dropwise to the zinc salt solution until the molar ratio of zinc ions and hydroxide ions in the mixed solution is 1:6. After stirring for 20 minutes, add an appropriate amount of tetradecyltrimethylammonium bromide at a concentration of 2.4 g per liter, stir and dissolve to obtain a reaction solution; seal the reactor, react at a temperature of 90 ° C for 4 hours, and cool to room temperature naturally. The product is filtered, washed with deionized water for 3 to 5 times, then washed with absolute ethanol for 3 to 5 times, and then dried naturally to obtain a one-dimensional zinc oxide nanometer material with good crystallinity.

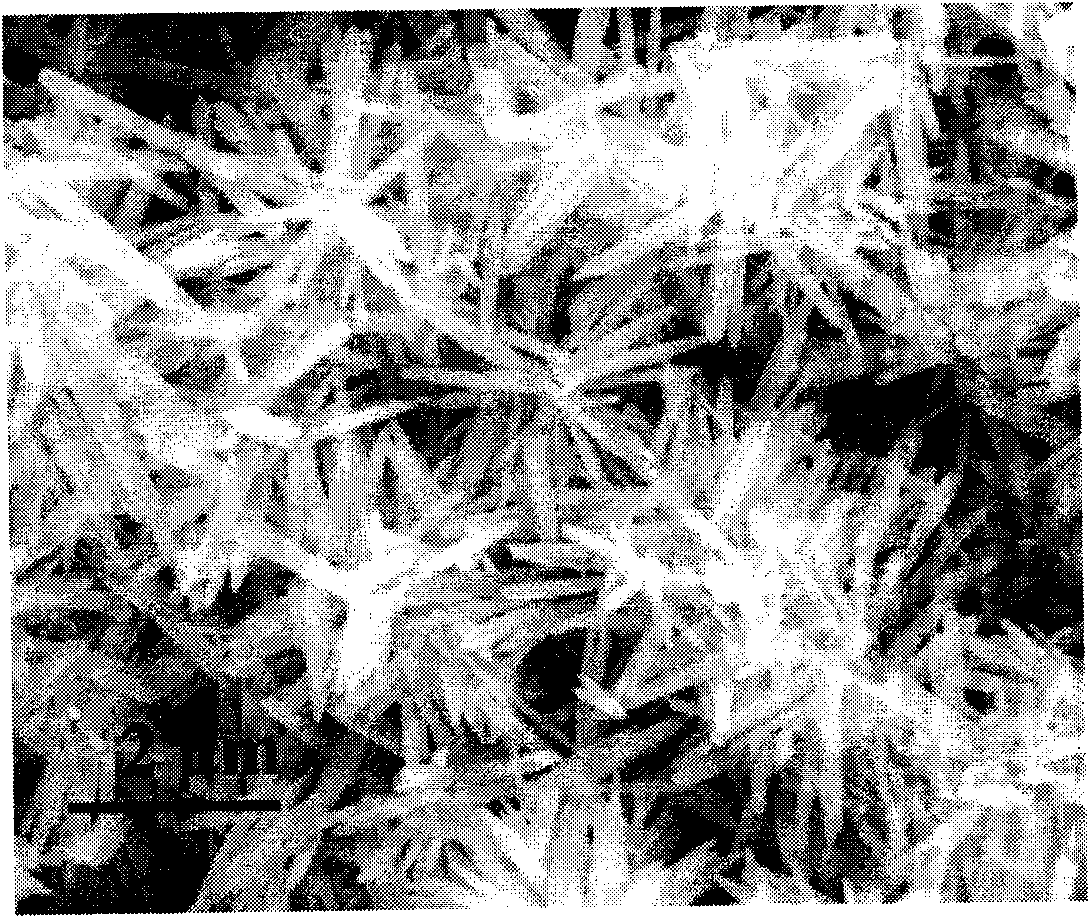

[0037] Scanning ...

Embodiment 3

[0039]A. ZnSO 4 Prepare a zinc salt solution with a concentration of 0.3 mol / L with deionized water, and take 20 ml and place it in a stirred reactor.

[0040] B. NaOH is prepared into a NaOH solution with a concentration of 2.4mol / L with deionized water.

[0041] C. Under stirring, the NaOH solution is slowly added dropwise to the zinc salt solution until the molar ratio of zinc ions and hydroxide ions in the mixed solution is 1:8. After stirring for 20 minutes, add an appropriate amount of cetyltrimethylammonium chloride (CTAC) at a concentration of 3.5 g per liter, stir and dissolve to obtain a reaction solution; seal the reactor, react at a temperature of 80 ° C for 6 hours, and cool naturally After reaching room temperature, the product is filtered, washed with deionized water for 3 to 5 times, and then washed with absolute ethanol for 3 to 5 times, and then dried naturally to obtain a one-dimensional zinc oxide nanomaterial with good crystallinity.

[0042] Scanning el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com