Preparation method of canna edulis ker polysaccharide polyphenol complex

The technology of canna and compound is applied in the field of preparation in the field of food technology, which can solve problems such as environmental pollution and resource waste, and achieve the effects of large output of raw materials, reduced damage, and reduced environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

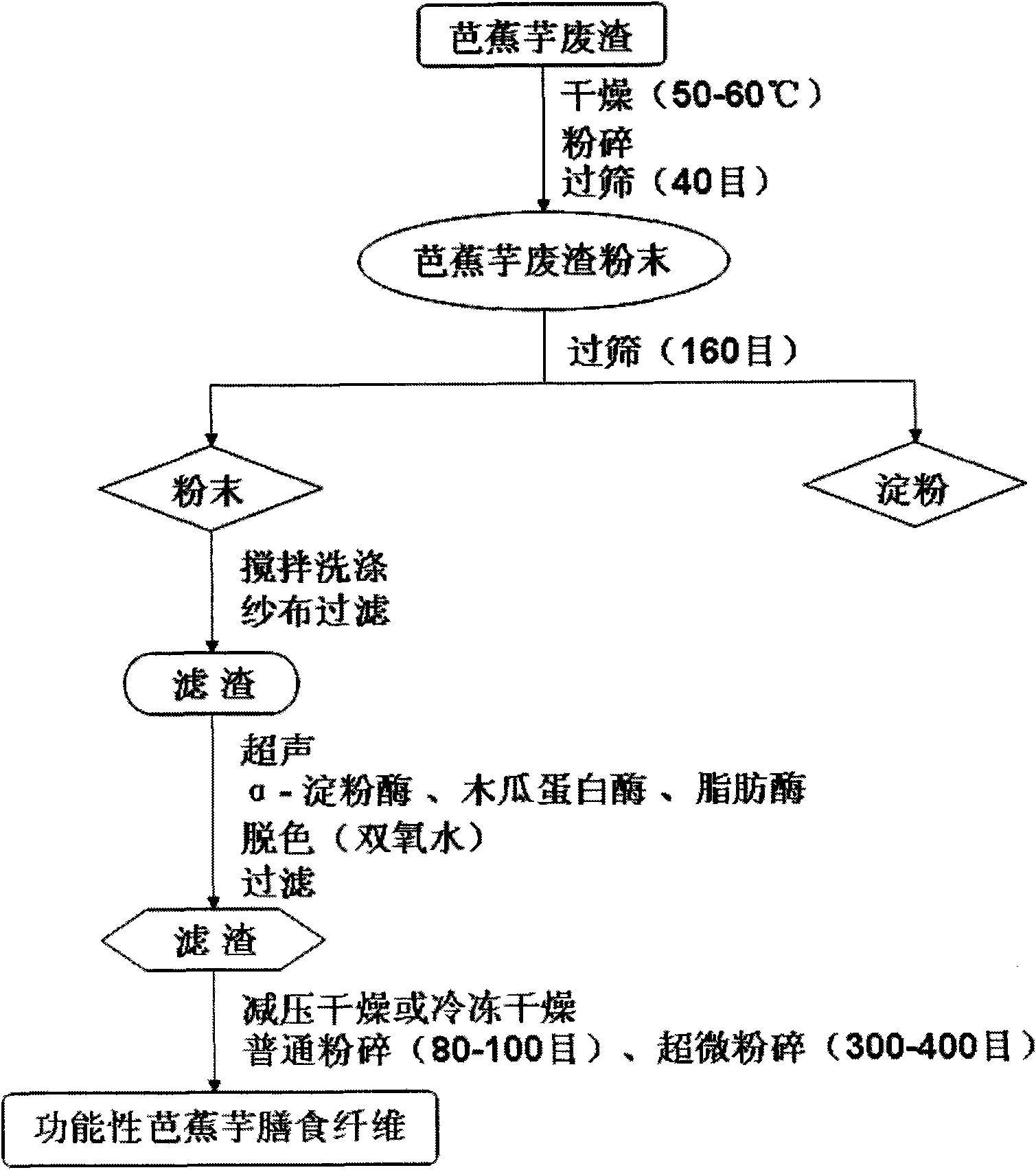

Image

Examples

Embodiment 1

[0021] Step 1. The waste residue of plantain taro comes from Guizhou Ziyun Jiahe Chemical Technology Co., Ltd. Dry the waste residue of plantain taro at 50°C, crush it, pass through a 40-mesh sieve, and then pass through a 160-mesh sieve to remove part of the starch. Collect the residue in the sieve and add 8 times the volume of water, stir and wash the filter residue at 30°C for 20 minutes, filter the filter residue with double-layer gauze; add water 8 times the volume of the filter residue to the filter residue, and ultrasonically treat it for 20 minutes to obtain a solution;

[0022] Step 2, adjusting the pH value of the solution to 8.2, adding thermostable α-amylase so that the mass fraction of amylase reaches 0.6‰, and stirring at 800 rpm at 95°C for 60 minutes;

[0023] Step 3, cooling the solution finally obtained in step 2 to 60°C, adding alkaline papain to make the mass fraction of protease reach 1‰, stirring at 800rpm for 60 minutes; then adding lipase to make the mas...

Embodiment 2

[0028] Step 1. The waste residue of plantain taro comes from Guizhou Ziyun Jiahe Chemical Technology Co., Ltd. Dry the waste residue of plantain taro at 60°C, crush it, pass through a 40-mesh sieve, and then pass through a 160-mesh sieve to remove part of the starch. Collect the residue in the sieve and add 10 times the volume of water, stir and wash the filter residue at 40°C for 10 minutes, filter the filter residue with double-layer gauze; add water 10 times the volume of the filter residue to the filter residue, and ultrasonically treat it for 30 minutes to obtain a solution;

[0029] Step 2, adjusting the pH value of the solution to 8.0, adding thermostable α-amylase so that the mass fraction of the amylase reaches 1‰, and stirring at 1200 rpm at 100°C for 30 minutes;

[0030] Step 3: Cool the solution finally obtained in Step 2 to 55°C, add alkaline papain to make the mass fraction of protease reach 2‰, stir at 1200rpm for 30 minutes; then add lipase to make the mass frac...

Embodiment 3

[0034] Step 1. The waste residue of plantain taro comes from Guizhou Ziyun Jiahe Chemical Technology Co., Ltd. Dry the waste residue of plantain taro at 55°C, crush it, pass through a 40-mesh sieve, and then pass through a 160-mesh sieve to remove part of the starch. Collect the residue in the sieve and add 8 times the volume of water, stir and wash the filter residue at 25°C for 10 minutes, filter the filter residue with double-layer gauze; add water 5 times the volume of the filter residue to the filter residue, and ultrasonically treat it for 15 minutes to obtain a solution;

[0035] Step 2, adjusting the pH value of the solution to 7.5, adding thermostable α-amylase so that the mass fraction of amylase reaches 0.7‰, and enzymatically hydrolyzing at 96° C. for 45 minutes;

[0036] Step 3, cooling the solution finally obtained in step 2 to 50°C, adding alkaline papain to make the mass fraction of protease reach 1.5‰, and enzymolysis for 45 minutes; then add lipase to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com