One-step in situ synthesis method for preparing transparent organic inflaming retarding composite material

A composite material and in-situ synthesis technology, which is applied in the field of organic compound + inorganic synthesis of flame-retardant transparent materials, can solve the problems of inability to realize the amount of magnesium hydroxide, complexity, and inability to realize nanoscale dispersion of flame retardant magnesium hydroxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] The present invention will be further described below in conjunction with accompanying drawing:

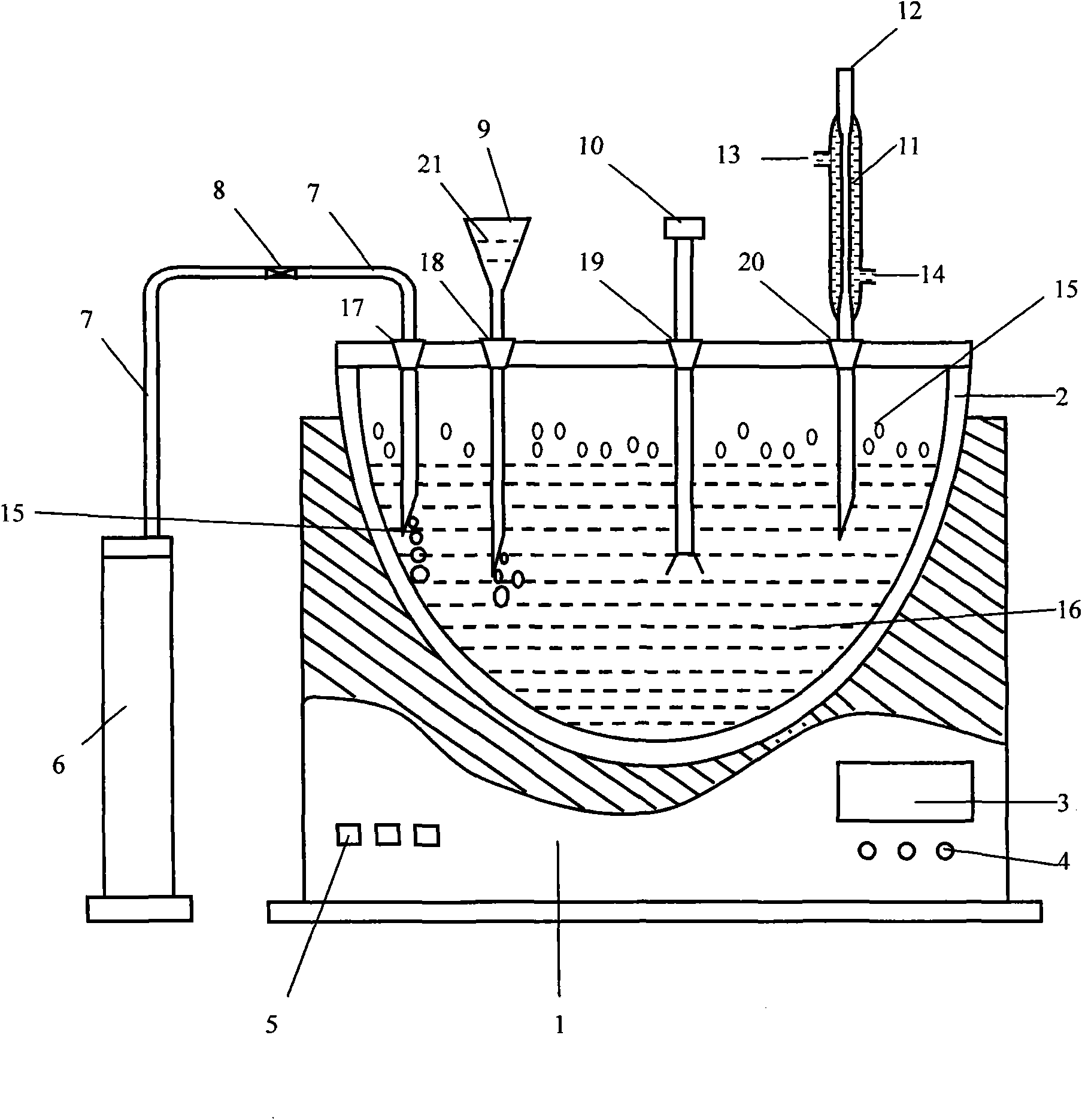

[0114] figure 1 As shown, the state diagram for the preparation of organic flame-retardant transparent materials for one-step in-situ synthesis is one-step in-situ synthesis in a four-necked flask. Each step must be strictly controlled and the data must be accurate.

[0115] The chemical substances and materials used in the synthesis are determined according to the preset value range, in grams, milliliters, centimeters 3 is the unit of measurement.

[0116] The various utensils used in the synthesis should be cleaned first, and no impurities should enter to prevent the production of unknown by-products.

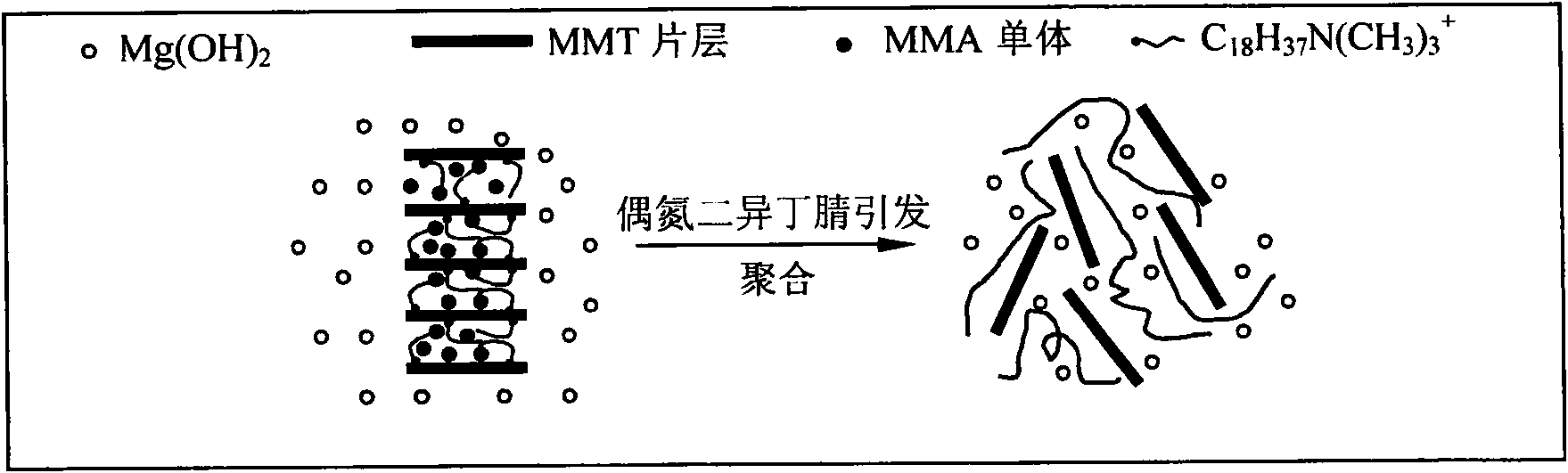

[0117] figure 2 As shown, it is the state diagram of the composite process of the polymerization reaction of the three-phase material. It can be seen from the figure that the octadecyltrimethylammonium ion enters between the sodium-based montmorillonite sheets through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com