A kind of graphene/polyethylene terephthalate composite fiber and preparation method thereof

A polyethylene terephthalate and composite fiber technology, applied in the direction of single-component polyester rayon, can solve the problems of high addition of inorganic powder, damaged mechanical properties, small specific surface area, etc., to achieve The effect of good dispersion, good mechanical properties, and high UV absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of graphite oxide:

[0034] Add 30g of sodium nitrate and 675mL of concentrated sulfuric acid into a three-necked flask, stir slowly in an ice-water bath, add 75g of potassium permanganate, 15g of graphite, bath in ice-water for 30min, mechanically stir at room temperature, heat in a water bath to 35°C, keep for 5h, and then pour 1300mL into it. Heat to 98°C in deionized water, keep stirring, add hydrogen peroxide after about 30 minutes until no gas comes out, and the reaction is over. Wash the product with 10% dilute hydrochloric acid to remove metal ions, and then dry it to obtain graphite oxide.

[0035] (2) Preparation of graphene:

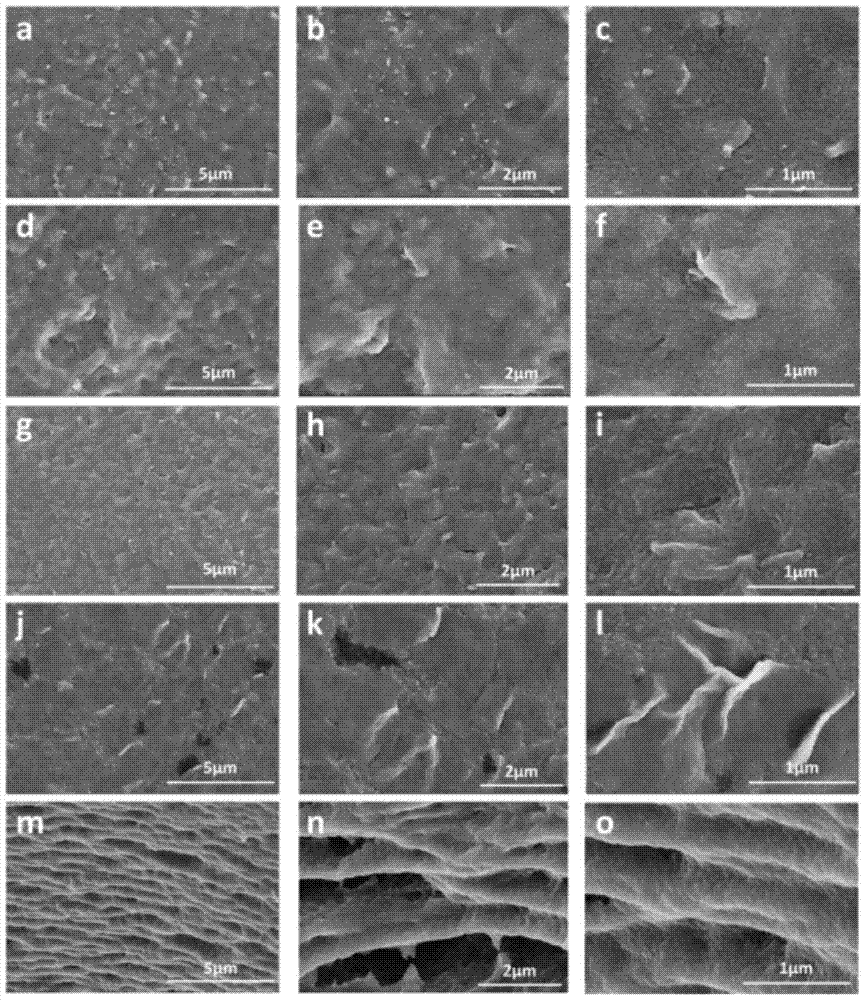

[0036] Disperse 1.0 g of graphite oxide into 100 g of water by ultrasonic stripping with a probe, the power is about 40 W, and the ultrasonic time is 1.5 hours to obtain dispersion A. Add the aqueous solution of graphite oxide into 400 g of N-methylpyrrolidone (NMP), continue ultrasonic dispersion, observe with an opti...

Embodiment 2

[0047] The preparation of the graphene oxide dispersion is the same as in Example 1.

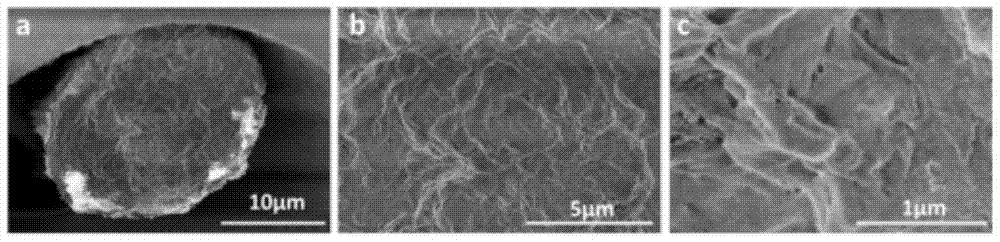

[0048] Preparation of composite resin masterbatch:

[0049] 0.4g of graphene obtained by thermal reduction is ultrasonically dispersed in o-chlorophenol with a probe. After about 1.5 hours, use an optical microscope to observe that the dispersion is good, then add PET powder, stir magnetically, heat the oil bath to reflux at 165°C, and dissolve completely after about 3 hours. Stop heating and stirring, mash after cooling to room temperature, add a large amount of acetone to sonicate. Wash off the o-chlorophenol, and wash with suction until the filtrate is colorless. Dry in a blast oven at 60°C, and dry in a vacuum oven at 120°C for 48 hours.

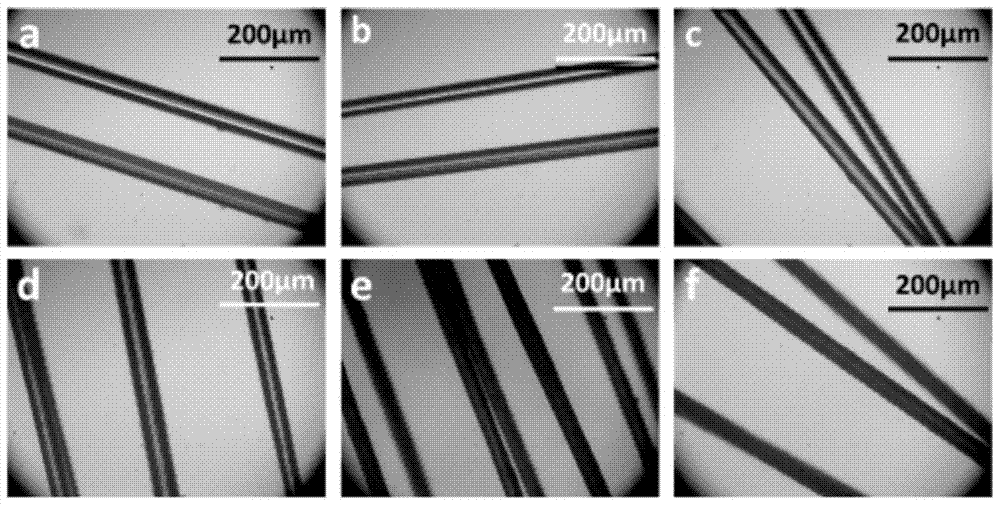

[0050] Preparation of graphene modified composite fiber:

[0051] (1) Get 5 mass parts of masterbatch, 95 mass parts of PET chips;

[0052] (2) Send the masterbatch and PET chips into a vacuum drum dryer for drying treatment. The drying process is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com