Synthesis method of thermosetting phenol-formaldehyde resin in solid at normal temperature

A technology of phenolic resin and synthesis method, applied in the field of resin synthesis, to achieve the effect of preventing the formation of gel, less environmental pollution and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

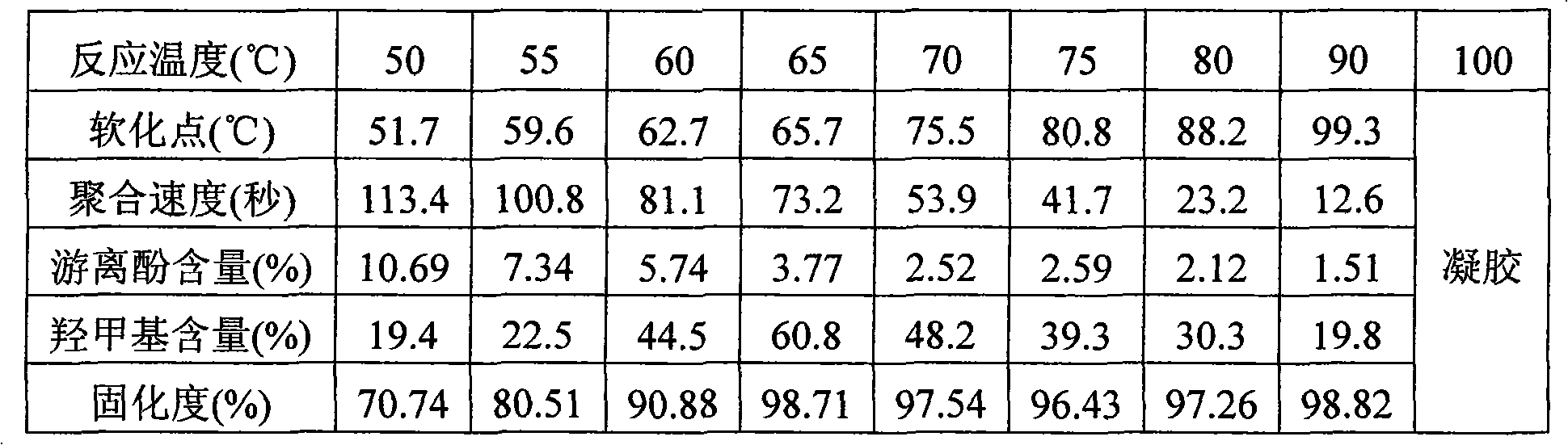

Examples

Embodiment 1

[0027] Take 1 mole of the raw material phenol used in the preparation of solid thermosetting phenolic resin as an example. Other raw materials used and their proportioning and preparation methods are as follows:

[0028] 1. Ingredients

[0029] Take 94g of phenol, 146g of formaldehyde with a mass concentration of 37%, and 11.20g of potassium hydroxide into a 500mL three-necked flask, and stir evenly, that is, the molar ratio of phenol to formaldehyde and alkali is 1:1.8:0.2.

[0030] 2. Reflux reaction

[0031] The reactant was heated to 65° C. under stirring, and reacted at constant temperature for 4 hours.

[0032] 3. Vacuum dehydration

[0033] After the reaction, put the product into a vacuum drying oven with a vacuum degree of -0.07MPa, and dry it at 85°C for 2.5 hours to prepare a solid thermosetting phenolic resin at room temperature.

[0034] 4. Characterization

[0035] The prepared thermosetting phenolic resin, which is solid at room temperature, uses an automati...

Embodiment 2

[0043] Take 1 mole of the raw material phenol used in the preparation of solid thermosetting phenolic resin as an example. Other raw materials used and their proportioning and preparation methods are as follows:

[0044] Take 94g of phenol, 81.08g of formaldehyde with a mass concentration of 37%, and 1.12g of potassium hydroxide into a 500mL three-necked flask, and stir evenly, that is, the molar ratio of phenol to formaldehyde and alkali is 1:1.0:0.02. The other steps are the same as in Example 1, to prepare a solid thermosetting phenolic resin at room temperature.

Embodiment 3

[0046] Take 1 mole of the raw material phenol used in the preparation of solid thermosetting phenolic resin as an example. Other raw materials used and their proportioning and preparation methods are as follows:

[0047] Take 94g of phenol, 243.24g of formaldehyde with a mass concentration of 37%, and 21.28g of potassium hydroxide into a 500mL three-necked flask, and stir evenly, that is, the molar ratio of phenol to formaldehyde and alkali is 1:3.0:0.38. The other steps are the same as in Example 1, to prepare a solid thermosetting phenolic resin at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com