Dedicated sealant surface layer coating for high-performance storage tank bottom and preparation method thereof

A surface coating, high-performance technology, applied in the field of chemical building materials, can solve the problems of poor performance such as the sealing and deformation of the bottom of the storage tank, low temperature flexibility, corrosion of the bottom of the tank, etc., and achieves good elasticity, high adhesion, The effect of preventing corrosion of the tank bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

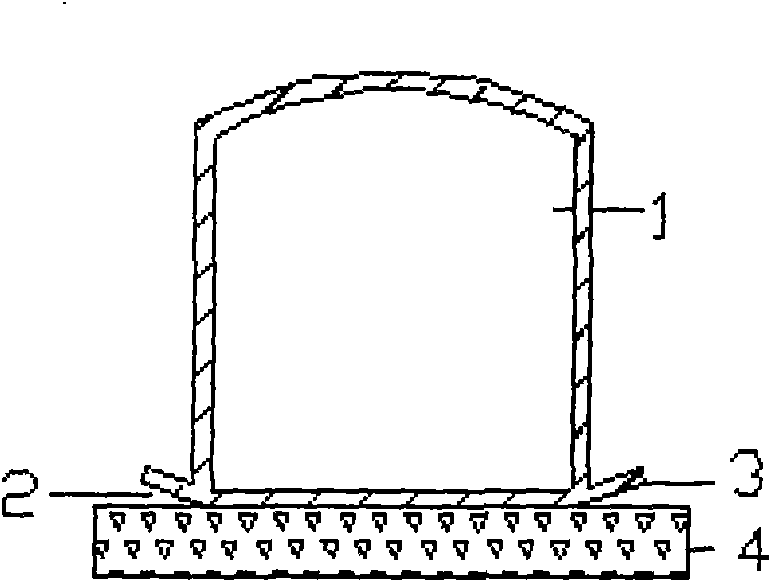

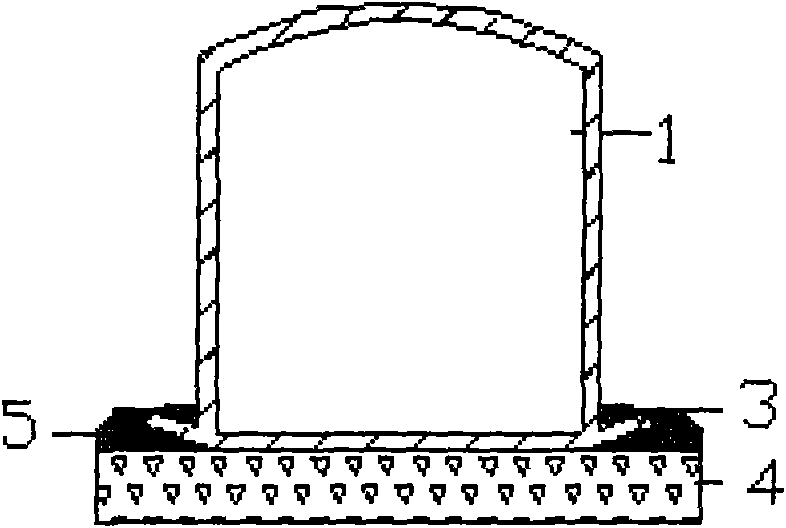

Image

Examples

Embodiment 1

[0065] 1. Formula of CTPU special sealant surface coating for high-performance storage tank bottom:

[0066] Component A:

[0067] Toluene diisocyanate 12kg,

[0068] Diphenylmethane diisocyanate 35kg,

[0069] TBIOL2000 polyether 80kg,

[0070] TMN3000 20kg,

[0071] TBIOL1000 polyether 5kg.

[0072] Component B:

[0073] Amine chain extender 10kg,

[0074] TMN3000 polyether 10kg,

[0075] TBIOL2000 polyether 35kg,

[0076] Plasticizer 110: dibutyl phthalate 10kg,

[0077] Wetting agent T80 5.5kg,

[0078] Reflective agent 2.0kg,

[0079] Antioxidant 1010 1.0kg,

[0080] UV absorber uv327 0.8kg,

[0081] Color and filler: talcum powder 14kg, titanium dioxide 5.5kg, china clay 3kg, kaolin 3kg, white carbon black 0.15kg, carbon black 0.1kg,

[0082] Diluent: xylene 5kg, ethyl acetate 3kg, butanone 2kg,

[0083] Accelerator: lead isooctanoate 1kg,

[0084] Defoamer: defom6800 0.3kg,

[0085] Leveling agent: levelslip810 0.2kg,

[0086] Adhesion enhancer: adheren...

Embodiment 2

[0092] Formula of CTPU special sealant surface coating for high-performance storage tank bottom:

[0093] Component A:

[0094] Toluene diisocyanate 8kg,

[0095] Diphenylmethane diisocyanate 20kg,

[0096] TBIOL2000 polyether 50kg,

[0097] TMN3000 15kg,

[0098] TBIOL1000 polyether 0kg.

[0099] Component B:

[0100] Amine chain extender 4kg,

[0101] TMN3000 polyether 6kg,

[0102] TBIOL2000 polyether 27.5kg,

[0103] Plasticizer 110: dioctyl phthalate 8kg,

[0104] Wetting agent T80 5kg,

[0105] Accelerator: stannous octoate 1.5kg,

[0106] UV absorber uv327 0.8kg,

[0107] Reflective agent 8kg,

[0108] Antioxidant 1010 2.0kg,

[0109] Color and filler: talcum powder 16kg, titanium dioxide 5kg, china clay 4kg, kaolin 1kg, white carbon black 0.15kg, carbon black 0.1kg.

[0110] Diluent: xylene 7kg, ethyl acetate 3kg,

[0111] Defoamer: defom5300 0.3kg,

[0112] Leveling agent: levelslip875 0.2kg,

[0113] Adhesion enhancer: adherent1051 0.1kg.

[0114] T...

Embodiment 3

[0116] Formula of CTPU special sealant surface coating for high-performance storage tank bottom:

[0117] Component A:

[0118] Toluene diisocyanate 15kg,

[0119] Diphenylmethane diisocyanate 25kg,

[0120] TBIOL2000 polyether 60kg,

[0121] TMN3000 10kg,

[0122] TBIOL1000 polyether 5kg.

[0123] Component B:

[0124] Amine chain extender 5kg,

[0125] TMN3000 polyether 5kg,

[0126]TBIOL2000 polyether 30kg,

[0127] Plasticizer 110: dibutyl phthalate 8kg,

[0128] Wetting agent T80 5kg,

[0129] Reflective agent 3.0kg,

[0130] Antioxidant 1010 1.0kg,

[0131] UV absorber 327 0.8kg,

[0132] Color and filler: talcum powder 10kg, titanium dioxide 5kg, china clay 4kg, kaolin 7kg, white carbon black 0.15kg, carbon black 0.1kg

[0133] Thinner: xylene 6kg, acetone 4kg,

[0134] Accelerator: lead isooctanoate 2.0kg,

[0135] Defoamer: defom 5500 0.3kg,

[0136] Leveling agent: levelslip8100 0.2kg,

[0137] Adhesion enhancer: KL 0.1kg.

[0138] The production pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com