Method for producing hydrogen by bacterial fermentation

A technology for producing hydrogen and microorganisms, which is applied in the field of bacterial fermentation to produce hydrogen, and can solve problems such as little energy regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, Enterobacter aerogenes uses sodium pyrophosphate as phosphorus source to produce hydrogen

[0021]1) Add sodium pyrophosphate to the basal medium (glucose 15.0g / L, tryptone 5.0g / L, ammonium sulfate 2.0g / L, magnesium sulfate 0.2g / L) so that the final concentration is 0.01mol / L, The pH was adjusted to 6.0, and the medium without sodium pyrophosphate was used as a control. Enter the activated Enterobacter aerogenes IAM1183 (Enterobacter aerogenes) in the medium, so that the initial content of Enterobacter aerogenes IAM1183 is 5×10 8 CFU / ml, cultured at 37°C, 170rpm for 15h.

[0022] 2) Add sodium pyrophosphate to the basal medium (glucose 15.0g / L, tryptone 5.0g / L, ammonium sulfate 2.0g / L, magnesium sulfate 0.2g / L) so that the final concentration is 0.10mol / L, The pH was adjusted to 6.0, and the medium without sodium pyrophosphate was used as a control. Enter the activated Enterobacter aerogenes IAM1183 (Enterobacter aerogenes) in the medium, so that the in...

Embodiment 2

[0031] Example 2. Recombinant Enterobacter aerogenes uses sodium pyrophosphate as phosphorus source to produce hydrogen

[0032] The pMCL plasmid is used as the expression vector of Enterobacter aerogenes IAM1183 (Enterobac ter aerogenes), and the pMCL plasmid construction process is as follows:

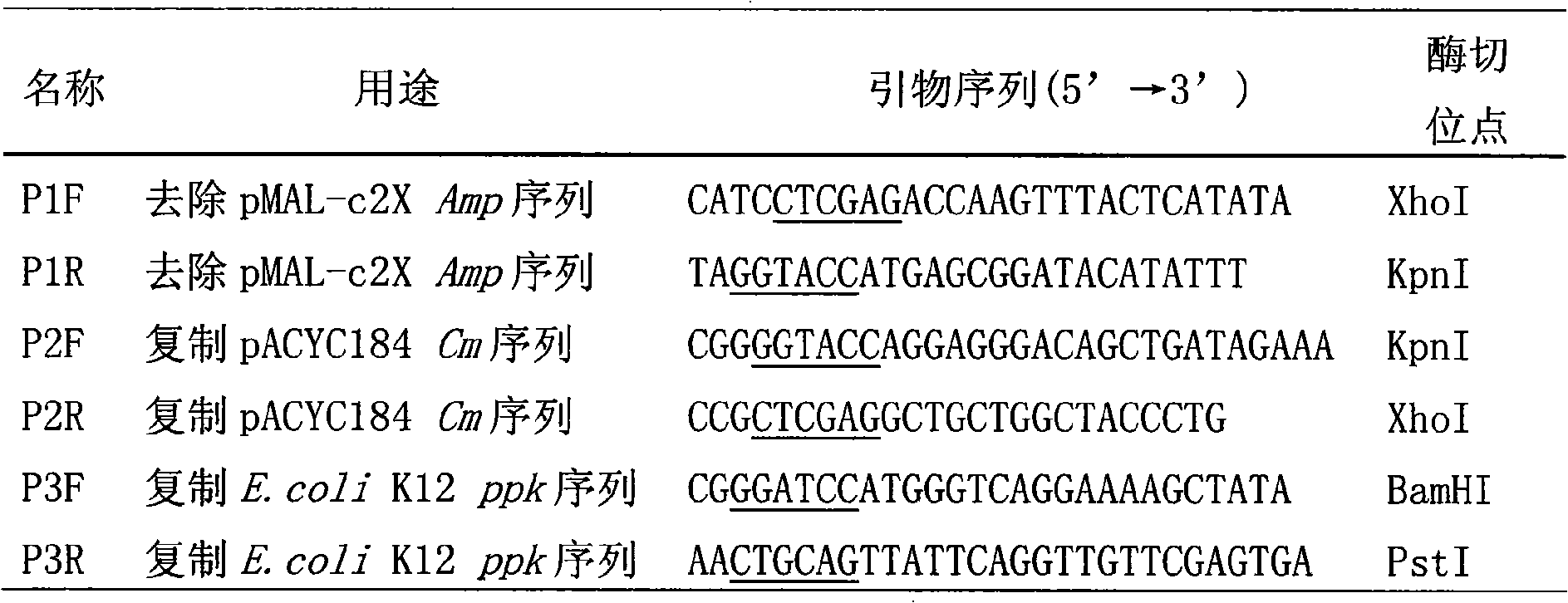

[0033] Use P1F and P1R primers (Table 1) to amplify the ampicillin resistance (Amp)-removed sequence on pMAL-c2X (purchased from NEB Company, No. N8076), and then digest with XhoI and KpnI to obtain product I;

[0034] PCR amplification conditions were: 94°C, 5min; 30 cycles, 94°C, 1min; 60°C, 3min; 72°C, 1min; final extension at 72°C for 5min, and finally 4°C storage.

[0035] Use primers P2F and P2R to amplify the chloramphenicol sequence (Cm) on pACYC184 (purchased from NEB Company, No. E4152S), and then clone it into the pMD-18T vector to obtain a recombinant vector. KpnI and XhoI digest the recombinant vector to obtain the product II;

[0036] PCR amplification conditions were...

Embodiment 3

[0049] Example 3, Enterobacter aerogenes produces hydrogen through aerobic-anaerobic conversion

[0050] 1) Add sodium dihydrogen phosphate to the basal medium (glucose 10.0g / L, tryptone 5.0g / L, ammonium sulfate 2.0g / L, magnesium sulfate 0.2g / L) to make the final concentration 0.01mol / L , the pH was adjusted to 6.0. Enter the activated Enterobacter aerogenes IAM1183 (Enterobacter aerogenes) in the culture medium, so that the initial content of Enterobacter aerogenes IAM1183 (Enterobacter aerogenes) is 5 × 10 8 CFU / ml, cultured at 37°C, 170rpm for 15h.

[0051]2) Add sodium dihydrogen phosphate to the basal medium (glucose 10.0g / L, tryptone 5.0g / L, ammonium sulfate 2.0g / L, magnesium sulfate 0.2g / L) to make the final concentration 0.10mol / L , the pH was adjusted to 6.0. Enter the activated Enterobacter aerogenes IAM1183 (Enterobacter aerogenes) in the culture medium, so that the initial content of Enterobacter aerogenes IAM1183 (Enterobacter aerogenes) is 5 × 10 8 CFU / ml, cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com