Preparation method for efficient tetramethylammonium hydroxide

A technology of tetramethylammonium hydroxide and tetramethylammonium bicarbonate salt, which is applied in the preparation of amino-substituted functional groups, organic chemistry, electrolysis process, etc., can solve the problems that the cost is difficult to meet market requirements, product pollution, consumption, etc., and achieve The effect of reducing the generation of industrial waste, production safety, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: the preparation method of this high-efficiency tetramethylammonium hydroxide, make tetramethylammonium bicarbonate salt with dimethyl carbonate and trimethylamine as reaction substance, wherein dimethyl carbonate: the mol ratio of trimethylamine is 1~1.5, and then use the three-chamber two-membrane electrolytic cell method to prepare tetramethylammonium hydroxide; ~100℃, trimethylamine gas space velocity: 50~100kg / h.

[0011] The specific method is: dimethyl carbonate is weighed and poured into the reaction kettle, after being fully mixed, the mixing temperature is controlled to be 30~100°C, trimethylamine is introduced at normal pressure according to the specified flow rate, and the heat preservation reaction is completed for four hours, and then poured into the third chamber Two-membrane electrolyzer for electrolysis, alkali flow at 5m 3 / h, the temperature rise rate is 1.5°C / 10 minutes, the current rise rate is 500A / 3 minutes, and the current rises to ...

Embodiment 2

[0012] Embodiment 2; According to the ionic membrane central control operation described in embodiment 1:

[0013] Confirm the start-up conditions: including the brine section, rectification power supply, public works (water, electricity, gas and gas), etc., have the start-up conditions, and the secondary brine system has the start-up conditions.

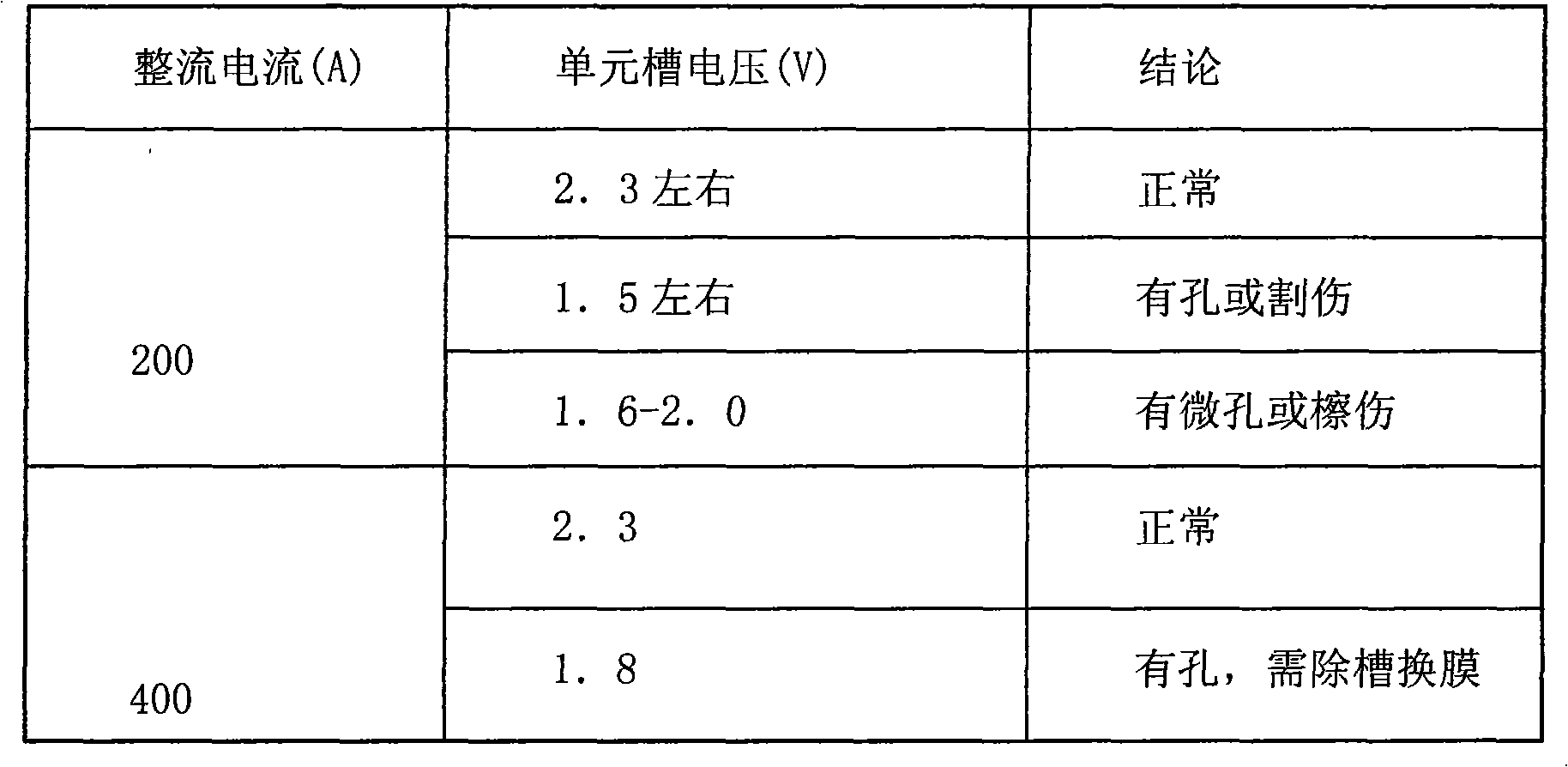

[0014] Send direct current to detect membrane leakage: first increase the current to 200A, check the voltage of each cell, and use a multimeter to measure the cell with abnormal voltage. Then increase the current to 500A, and increase the current to 4KA at a speed of 500A / 3 minutes. The conclusion is shown in Table 1.

[0015] Table 1 Conclusion table

[0016]

[0017] Single-tank driving: reduce the current speed to 500A / 3 minutes, check the overflow of lye and light salt water in each unit tank, and prevent the flow from being cut off. Single-tank parking: reduce the current speed to 500A / 3 minutes, check the overflow of lye ...

Embodiment 3

[0021] Embodiment 3: According to the resin tower treatment described in Embodiment 1: the flow rate of brine at full load of the resin tower is 32kg / h, and the two resin towers operate in series when they are normal.

[0022] The premise of resin tower regeneration: when the calcium and magnesium content at the outlet of the first resin tower exceeds 30ppb, it should be regenerated off-line. When the calcium and magnesium content at the outlet of the second resin tower exceeds the standard due to poor regeneration, it should be regenerated off-line. A tower must be regenerated every 48 hours. The basic steps of resin tower regeneration: place the resin tower to be regenerated offline, and run the other tower as a single tower, drain the brine in the tower into the waste water tank for 15 minutes, make the tower half full, and use 8M3 / h pure water Clean the resin tower from top to bottom for 1 hour, and drain the waste liquid into the waste liquid tank. Then fill the resin t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com