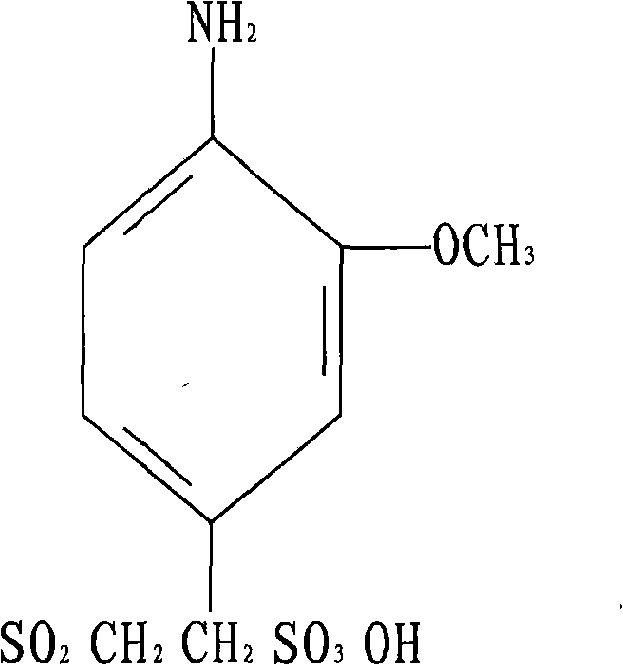

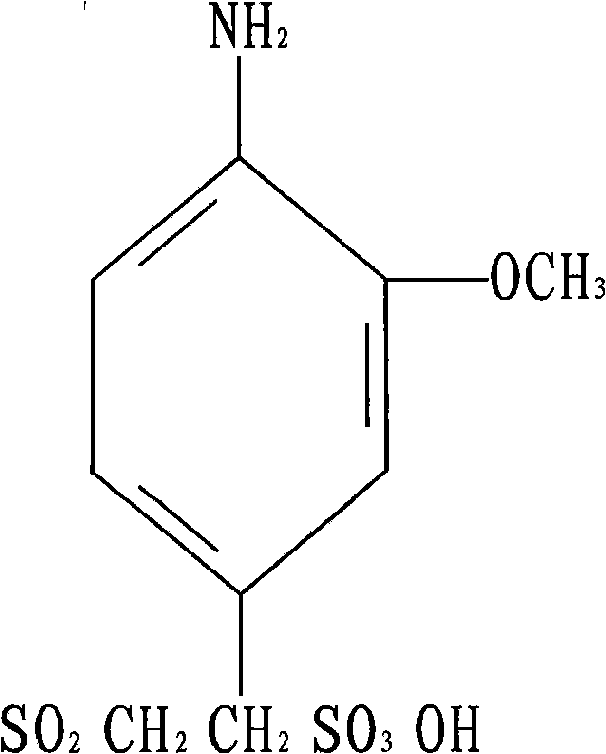

O-methoxy-beta-sulfuric ester ethyl sulfonyl aniline and preparation method thereof

A technology of ethyl sulfone aniline and oxygen pairs, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as complex production methods, high use cost, and effective content of only 95%, reaching The production method is simple and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

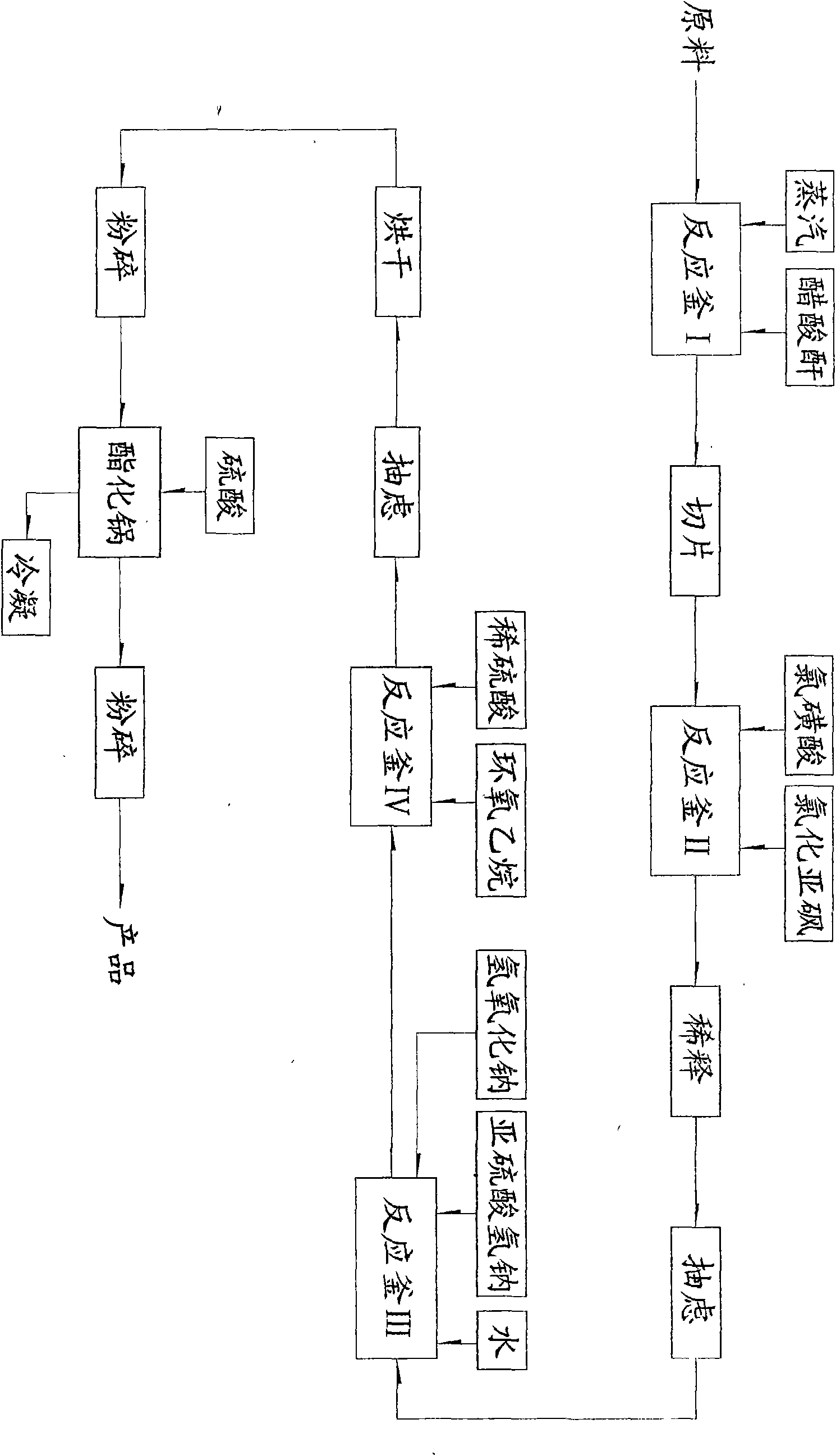

Method used

Image

Examples

Embodiment 1

[0022] a. Acetylation

[0023] With 100 grams of anthranil, add in reaction kettle 1 99 grams of acetic anhydride solution with 1 hour and stir, temperature is controlled at 75 ℃-78 ℃, after adding, keep warm for 1 hour, use vacuum pump and condenser steam heating to evacuate, in The acetic acid generated by the reaction was evaporated under vacuum conditions, and the reactant was sliced by a microtome to obtain 135 grams of o-methoxyacetanilide. The reaction formula is as follows:

[0024]

[0025] b. Sulfonation

[0026] Add 500 grams of chlorosulfonic acid and 50 grams of thionyl chloride into the reaction kettle II, start stirring, add 100 grams of the above-mentioned acetylated product o-methoxyacetanilide within 2 hours, and control the reaction temperature at 45°C-48°C. After the end point, slowly add the sulfonated solution into 3000 grams of ice water for dilution, the temperature is controlled at 10°C-15°C, after the dilution is completed, put the diluted solu...

Embodiment 2

[0038] a. Acetylation

[0039] Add 1000kg of anthranilic ether to 990kg of acetic anhydride solution in 2000L reactor I in 4 hours, start stirring, and control the temperature at 75°C-80°C. Vacuum, the acetic acid generated by the reaction was evaporated under vacuum conditions, and the reactant was sliced by a slicer to obtain 1350 kg of acetylated product o-methoxyacetanilide.

[0040] b. Sulfonation

[0041] Add 5500kg of chlorosulfonic acid and 500kg of thionyl chloride into the 5000L reactor II, start stirring, add the above-mentioned o-methoxyacetanilide 1000kg within 10 hours, and control the reaction temperature at 45°C-48°C. After the end of the reaction, the The sulfonated solution is slowly added into a dilution pot containing 15000kg of ice water for dilution. The temperature is controlled at 10°C-15°C. Oxy-p-β-sulfonyl chloride acetanilide.

[0042] c. Restore

[0043] Add 1000kg of sodium bisulfite into the reaction kettle III containing 3000kg of water to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com