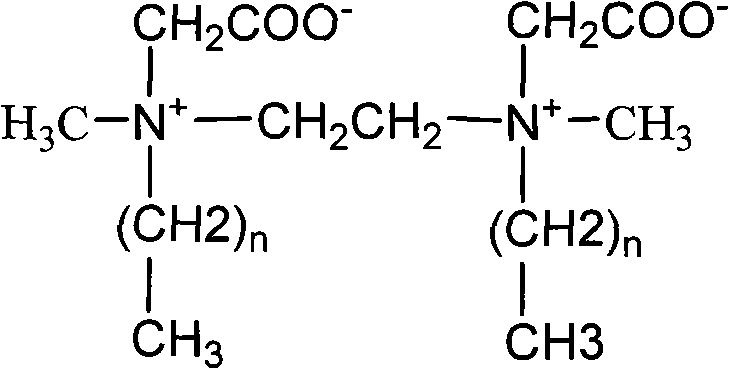

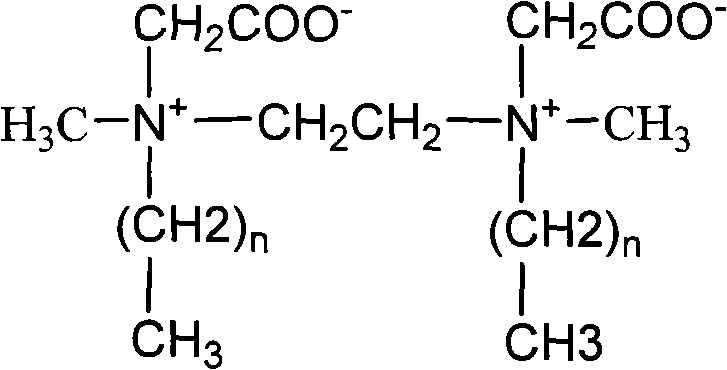

Carboxylic acid betaine type gemini surfactant and preparation method

A technology of surfactants and gemini surfaces, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve problems such as the limited variety of gemini surfactants, cumbersome operations, and harsh production process conditions of gemini surfactants , to achieve the effect of easy product, cheap raw material and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

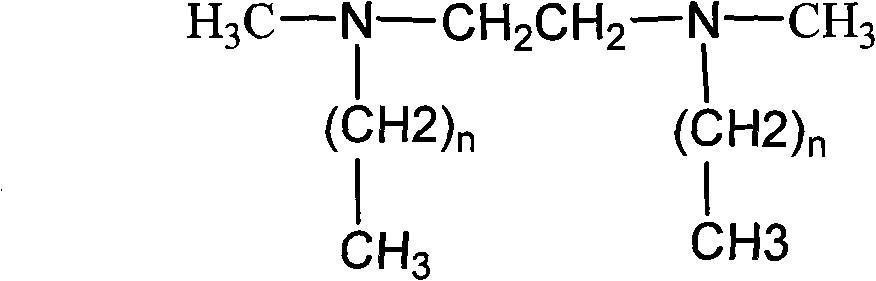

[0038] Embodiment 1: the preparation of N, N'-dialkyl-N, N'-dimethylethylenediamine

[0039] Add 20ml of absolute ethanol, 27ml of dodecane bromide and 4.4g of N,N'-dimethylethylenediamine in a dry container, stir at 30°C for 4 hours, then add 4g of sodium hydroxide, and continue stirring for 12 hours , filtered, the filtrate was adjusted to acidity with concentrated hydrochloric acid, 100ml of acetone was added to obtain a white precipitate, cooled to crystallize, filtered, the solid was heated to reflux with 50ml of 15% aqueous sodium hydroxide solution for 2 hours, cooled, the water phase was discarded, and the solid phase was washed with 70ml of ethyl acetate Recrystallization of the ester gave the product as a white solid.

Embodiment 2

[0040] Embodiment 2: the preparation of carboxylic acid betaine type amphoteric gemini surfactant

[0041] Dissolve 6.7g of bromoacetic acid in 50ml of methanol in a dry reactor, slowly add 2g of NaOH, after the reaction is complete, add 1g of potassium iodide and 8g of dimethyldidodecylethylenediamine, heat and reflux for 24 hours, after the reaction is complete , cooled, and the reaction solution was filtered, and the filtrate was distilled under reduced pressure at 70° C., and then dried to obtain a light yellow solid, which was the crude product surfactant. The solid was washed with acetone, and then recrystallized with absolute ethanol to obtain a white hygroscopic solid product.

Embodiment 3

[0042] The structural characterization of embodiment 3 product surfactants

[0043] (1) Take the product prepared in Example 2 as an example, carry out elemental analysis with an Italian CARLO ERBA 1106 elemental analyzer, and the result is N 3.84% 3.83%; C 50.50% 50.81%; H 9.98% 9.79%, and the calculated result is that the water content is 11.90%, illustrate that this surfactant is extremely hygroscopic, and the ratio of sodium bromide and surfactant is 2: 0.98, illustrates that 2 molecular sodium bromides are contained in each surfactant molecule.

[0044] (2) Taking the product prepared in Example 2 as an example, the photoelectron spectroscopy method was used to measure sodium and bromine in the sample, indicating that the sample contained sodium bromide, which was consistent with the elemental analysis results.

[0045] (3) The synthesized product was prepared with KBr salt flakes, and analyzed by NICOLET MX-1EFT-IR infrared spectrometer. Taking the product prepared in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com