Process for cleaning and recovering ammonia gas as byproduct of glyphosate

A glyphosate and ammonia technology, applied in the preparation/separation of ammonia, etc., can solve problems such as environmental pollution of glyphosate production tail gas, and achieve the effects of high recovery rate, good quality and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

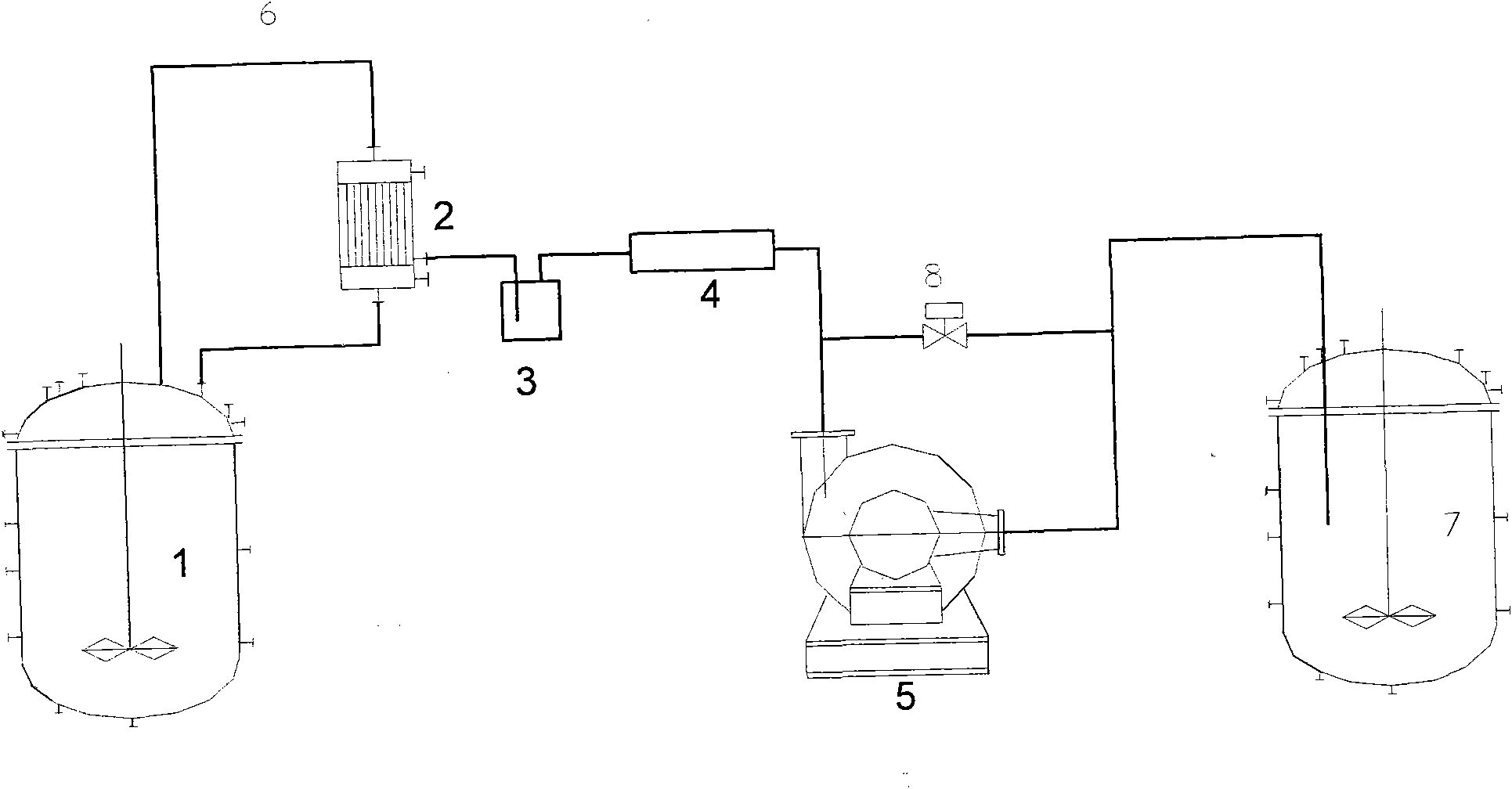

Image

Examples

Embodiment 1

[0021] Embodiment 1: A water-ring vacuum pump is used to provide ammonia gas delivery power, and the pressure is maintained at -0.01Mpa to -0.05Mpa. The ammonia gas is dried and purified by soda lime, and the method of bubbling and absorbing with an extension tube is used to obtain ammonia gas with a content of 30%. Back to the neutralization of glyphosate mother liquor.

Embodiment 2

[0022] Embodiment 2: A water ring vacuum pump is used to provide ammonia gas delivery power, and the pressure is maintained at -0.01Mpa to -0.05Mpa. The ammonia gas is dried and purified by calcium oxide, and the ammonia gas with a content of 60% is used as glyphosate mother liquor for spraying and absorption.

Embodiment 3

[0023] Embodiment 3: A water ring vacuum pump is used to provide ammonia gas delivery power, and the pressure is maintained at -0.01Mpa to -0.05Mpa. The ammonia gas is dried and purified by activated carbon, and then sprayed and absorbed with soft water through a packed tower to make 20% ammonia water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com