Compound blockage relieving agent and using method thereof

A composite plugging remover and plugging remover technology, applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve problems such as injury, low conversion rate of chlorine dioxide, explosion of the human respiratory system, etc. Achieve the effect of reducing construction cost, simple operation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

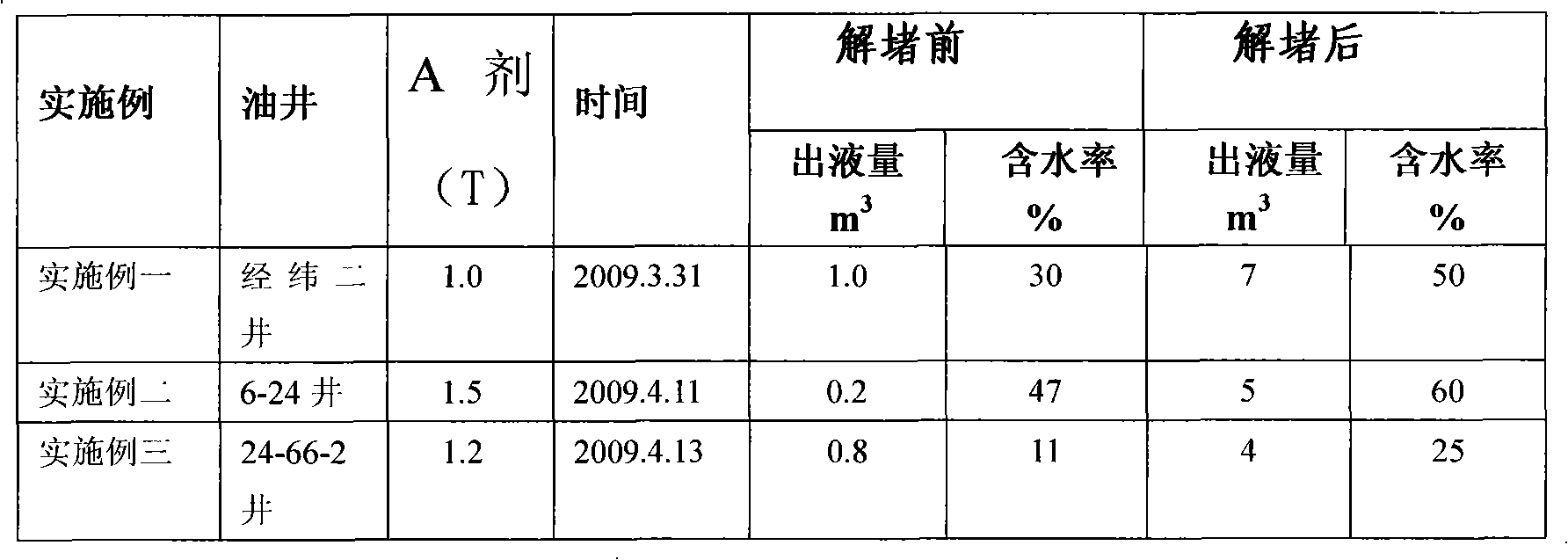

Embodiment 1

[0029] A composite plugging agent, consisting of agent A, agent B and agent C, agent A is a chlorine dioxide solution; agent B is a non-acid solid activator system; agent C is an organic phosphine corrosion inhibitor that resists chlorine dioxide oxidative corrosion , the mass ratio of agent A, agent B and agent C is 100:4:30

[0030] Agent A is a 2% stable chlorine dioxide solution in parts by mass.

[0031] B agent is made up of organic isocyanurate, inorganic sulfate and chlorate, and the organic isocyanurate in B agent is sodium dichloroisocyanurate, and its mass accounts for 40% of B agent; The inorganic sulfate is magnesium sulfate, and its mass accounts for 25% of agent B, and the chlorate is calcium chloride, and its mass accounts for 35%.

[0032] Agent C is 25% hexamethylenediamine tetramethylene phosphonic acid in parts by mass.

[0033] Its specific usage method is:

[0034] The first step is to inject the pre-liquid water 7T downhole through the casing;

[003...

Embodiment 2

[0043] A composite plug-removing agent, consisting of agent A, agent B and agent C, agent A is a chlorine dioxide solution; agent B is a non-acid solid activator system; agent C is an anti-oxidation corrosion inhibitor, and agent A, agent B The mass ratio of agent and agent C is 100:5:30.

[0044]Agent A is a 3% stable chlorine dioxide solution in parts by mass.

[0045] Agent B is composed of organic isocyanurate, inorganic sulfate and chlorate. The organic isocyanurate in agent B is trichloroisocyanuric acid, and its mass accounts for 45% of agent B; Sulphate is sodium sulfate, and its quality accounts for 30% of B agent. Chlorate is calcium chloride, which accounts for 25% by mass.

[0046] Agent C is 2-phosphonic acid butane-1,2,4-tricarboxylic acid with a mass fraction of 35%.

[0047] Its specific usage method is:

[0048] The first step is to inject 6T of pre-liquid water downhole through the casing;

[0049] The second step is to select the amount of plugging agen...

Embodiment 3

[0057] A composite plug-removing agent, consisting of agent A, agent B and agent C, agent A is a chlorine dioxide solution; agent B is a non-acid solid activator system; agent C is an anti-oxidation corrosion inhibitor, and agent A, agent B The mass ratio of agent and agent C is 100:6:20.

[0058] Agent A is a 2.5% stable chlorine dioxide solution in parts by mass.

[0059] B agent is made up of organic isocyanurate, inorganic sulfate and chlorate, and the organic isocyanurate in B agent is sodium dichloroisocyanurate, and its mass accounts for 43% of B agent; The inorganic sulfates are sodium bisulfate and magnesium sulfate, and their mass accounts for 25% and 5% of the B agent respectively. Chlorate is calcium chloride, which accounts for 27% by mass.

[0060] Agent C is 35% hexamethylenediamine tetramethylene phosphonic acid in parts by mass.

[0061] Its specific usage method is:

[0062] The first step is to inject 5T of pre-liquid water downhole through the casing; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com