Method for preparing negative pole material SnS2 of lithium ion battery

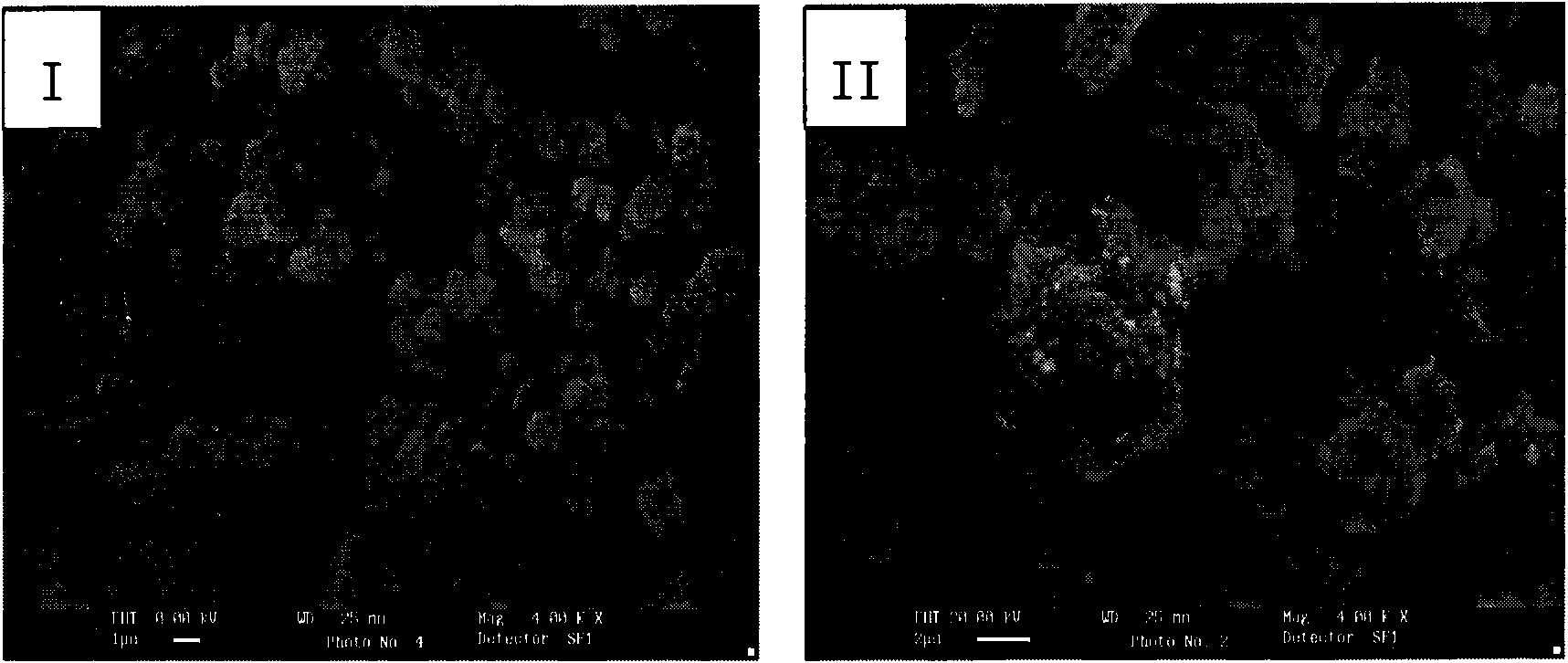

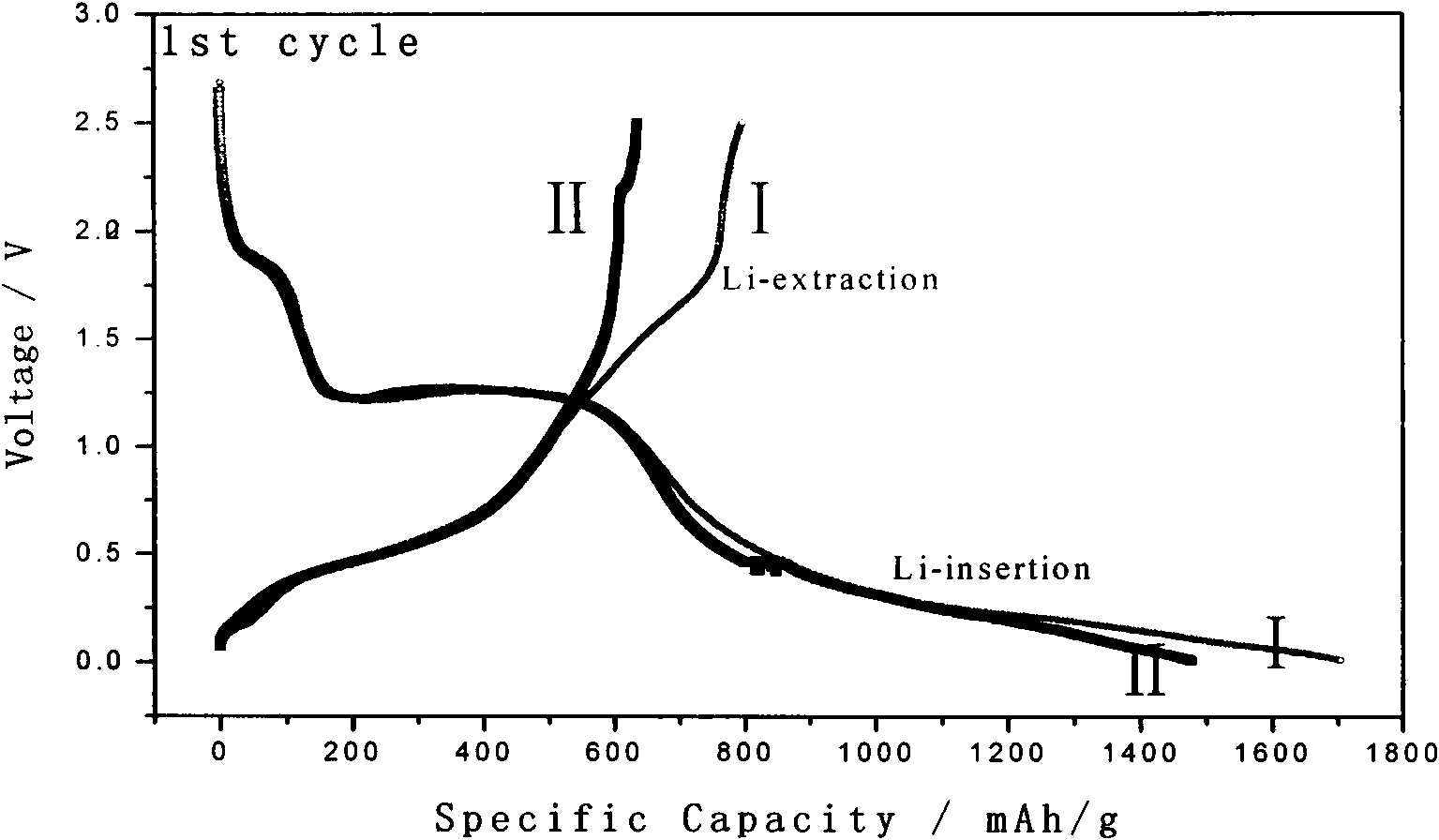

A technology for lithium ion batteries and negative electrode materials, which is applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as unevenness and large material particles, and achieve the effects of uniform distribution, high phase purity and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] (1) The ethylene glycol of 39ml is mixed with the water of 39ml as solvent;

[0021] (2) 1.2g of thioacetamide is added to the solvent prepared in (1), and stirred to completely dissolve it;

[0022] (3) Dissolve 4.5g tin tetrachloride pentahydrate in 12ml concentrated hydrochloric acid, stir to make it evenly mixed;

[0023] (4) Add the solution prepared in (2) to the solution prepared in (3), and stir to make it evenly mixed;

[0024] (5) Add the mixed solution prepared in (4) into the self-boosting reactor, seal it, the reaction temperature is 120°C, and the reaction time is 12h;

[0025] (6) After the reaction is completed, the reaction kettle is taken out and cooled to room temperature naturally, and the turbid liquid containing the yellow precipitate is suction-filtered, washed, and dried to obtain SnS 2 material, the resulting SnS 2 The material is used as the active material of the negative electrode material of the lithium ion battery.

[0026] SnS 2 Mix w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com