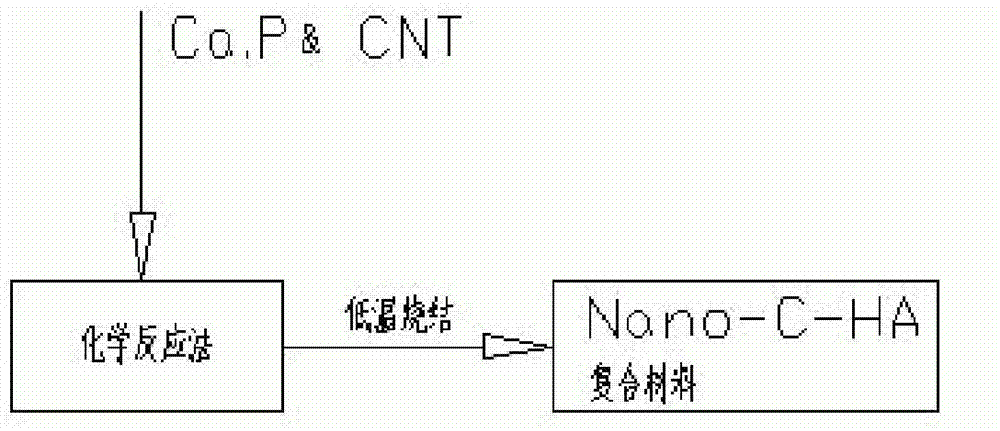

Multiple mesh nanometer carbon-hydroxyapatite composite material and preparation method thereof

A nano-hydroxyapatite and hydroxyapatite technology, which is applied in the field of nanocomposite material science and engineering, can solve the problems of uneven dispersion of carbon nanotubes, poor performance consistency, and agglomeration of carbon nanotubes, and is beneficial to large-scale production. Industrialized production, low cost, and the effect of enhancing interfacial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Weigh 0.7100g of phosphorus pentoxide, dissolve the weighed phosphorus pentoxide into 20ml of absolute ethanol under room temperature and medium-speed magnetic stirring, and keep stirring for 1h to obtain solution A;

[0042] 2. Accurately weigh 3.9412 g of calcium nitrate tetrahydrate with an electronic analytical balance, dissolve the weighed calcium nitrate tetrahydrate into 20 ml of absolute ethanol at room temperature and under medium-speed magnetic stirring, and continue stirring for 1 hour to obtain solution B;

[0043] 3. Weigh 0.1860g of CNTs into a beaker, add 20ml of absolute ethanol to the beaker, place it in an ultrasonic disperser and disperse it ultrasonically for 2 hours while passing in hydrogen peroxide, so that the CNTs are evenly dispersed, and a C solution is obtained;

[0044] 4. Under the condition of medium-speed magnetic stirring, slowly inject solution C into solution B successively, and keep stirring for 20 minutes. Then slowly inject soluti...

Embodiment 2

[0048] 1. Weigh 1.4200g of phosphorus pentoxide, dissolve the weighed phosphorus pentoxide into 20ml of absolute ethanol under room temperature and medium-speed magnetic stirring, and keep stirring for 1h to obtain solution A;

[0049] 2. Accurately weigh 7.8824 g of calcium nitrate tetrahydrate with an electronic analytical balance, dissolve the weighed calcium nitrate tetrahydrate into 20 ml of absolute ethanol at room temperature and under medium-speed magnetic stirring, and continue stirring for 1 hour to obtain solution B;

[0050] 3. Weigh 0.5906g of CNTs and put them into a beaker, add 20ml of absolute ethanol into the beaker, put it in an ultrasonic disperser and disperse it ultrasonically for 2 hours while passing in hydrogen peroxide, so that the CNTs are evenly dispersed, and a C solution is obtained;

[0051] 4. Under the condition of medium-speed magnetic stirring, slowly inject solution C into solution B successively, and keep stirring for 20 minutes. Then slowly ...

Embodiment 3

[0055] 1. Weigh 0.7100g of phosphorus pentoxide, dissolve the weighed phosphorus pentoxide into 20ml of absolute ethanol under room temperature and medium-speed magnetic stirring, and keep stirring for 1h to obtain solution A;

[0056] 2. Accurately weigh 3.9412 g of calcium nitrate tetrahydrate with an electronic analytical balance, dissolve the weighed calcium nitrate tetrahydrate into 20 ml of absolute ethanol at room temperature and under medium-speed magnetic stirring, and continue stirring for 1 hour to obtain solution B;

[0057] 3. Weigh 2.2000g of CNTs into a beaker, add 20ml of absolute ethanol into the beaker, place it in an ultrasonic disperser and disperse it ultrasonically for 2 hours while passing in hydrogen peroxide, so that the CNTs are evenly dispersed, and a C solution is obtained;

[0058] 4. Under the condition of medium-speed magnetic stirring, slowly inject solution C into solution B successively, and keep stirring for 20 minutes. Then slowly inject solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com