Wall-flow honeycomb ceramic filter

A technology of honeycomb ceramics and filter body, which is applied in the direction of filtration and separation, ceramic molding machines, mechanical equipment, etc., can solve the problems of high thermal expansion coefficient and mechanical strength, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

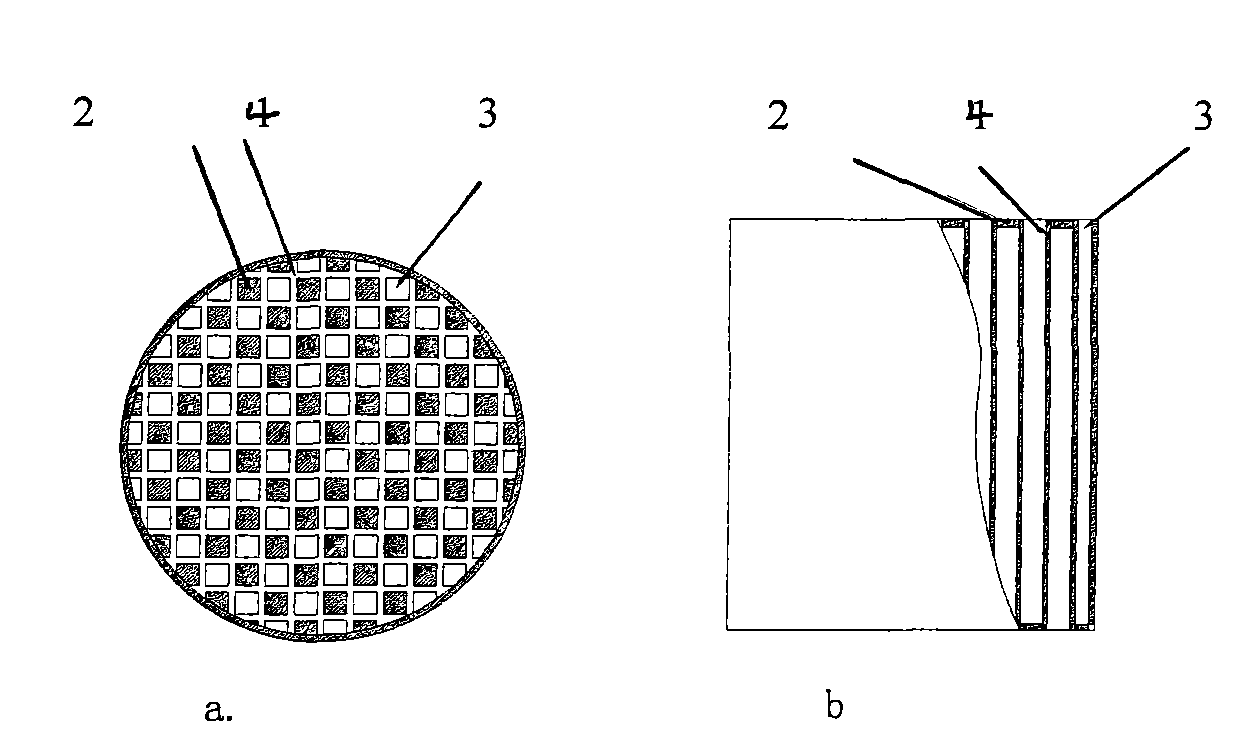

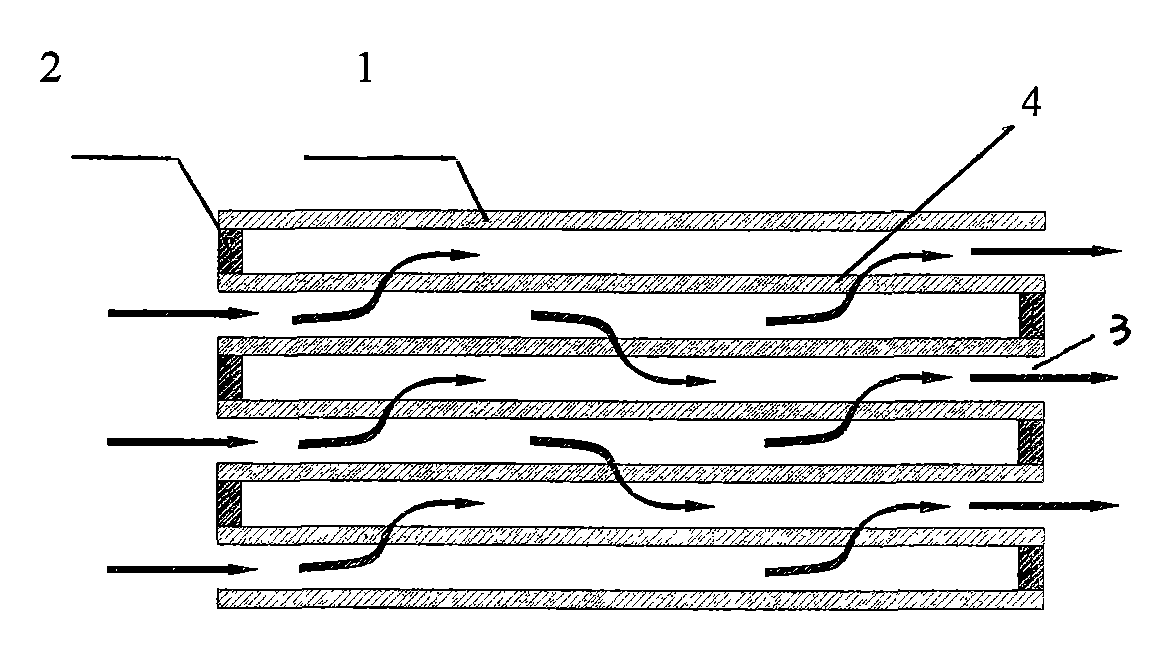

[0019] Wall-flow honeycomb ceramic filters such as figure 1 , figure 2 Shown: 1 is the outermost wall, 2 is the closed cell at the end, 3 is the opening at the end, and 4 is the filter wall.

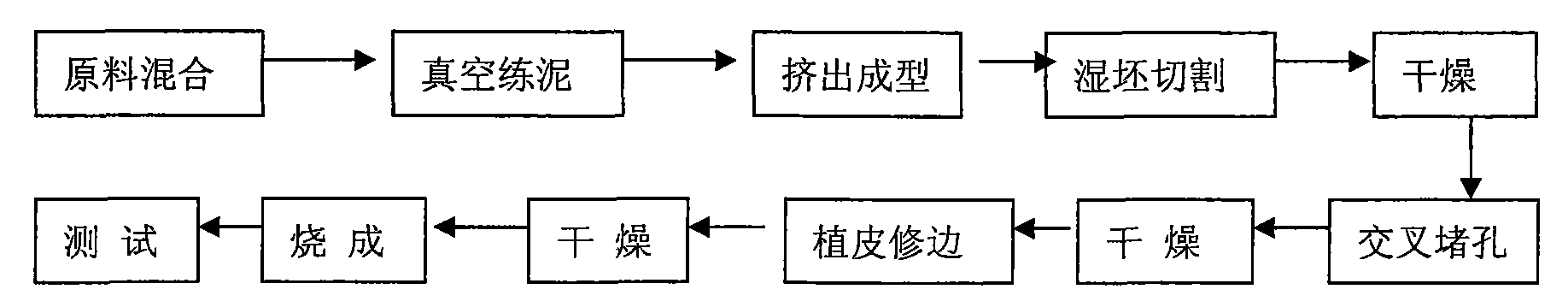

[0020] The embodiment of the wall-flow honeycomb ceramic filter body includes raw material processing, molding and firing, and the specific technical route is as follows (see image 3 ):

[0021]First, 35-45 parts of kaolin, with an average particle size of ≤5μm, 20-30 parts of talc, with an average particle size of 15μm, 4-9 parts of α-alumina, with an average particle size of ≤2μm, a pore-forming agent (including carbon particles or organic High polymer molecular particles can also be a mixture of the two, and the weight ratio of the two mixtures is 2-8:8-2; carbon particles can be used alone, including coal powder, etc., and organic polymer particles can be used alone, including a variety of polymer particles. Or fibrous polymers, such as polyethylene, polypropylene, polyester, al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com