Low-volatization unsaturated polyester resin suitable for large glass steel structural layer and manufacturing method thereof

A polyester resin and unsaturated technology, which is used in the production method of resin and the field of low-volatile unsaturated polyester resin for glass fiber reinforced plastics, can solve the problems of health hazards, exothermic peak height and environmental pollution of construction workers, and achieve excellent mechanical properties. , good water resistance, high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

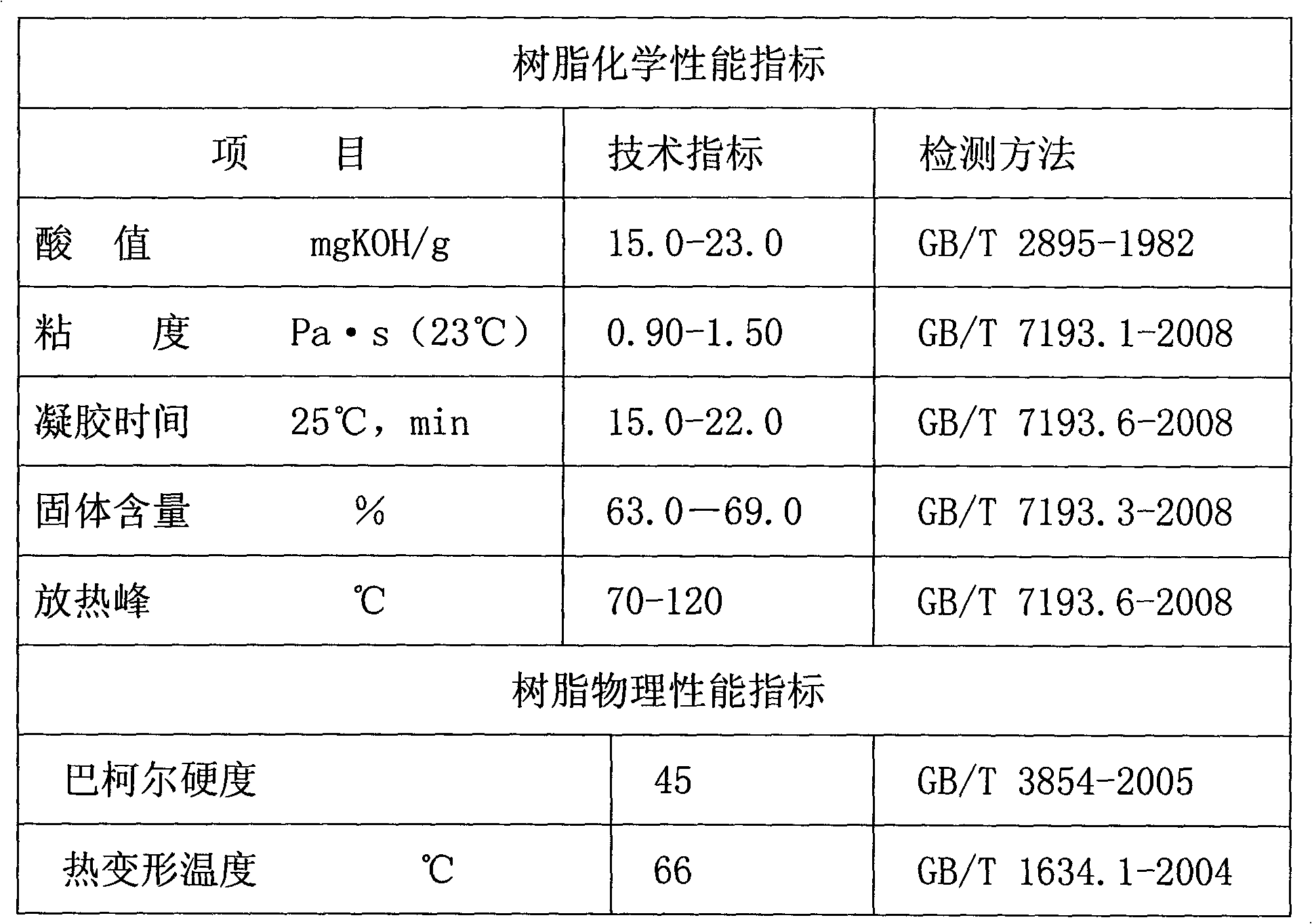

[0026] Low volatility unsaturated polyester resin suitable for large FRP structure layer, which is prepared from the following raw materials: propylene glycol 119Kg, ethylene glycol 11Kg, adipic acid 4Kg, phthalic anhydride 140Kg, maleic anhydride 54Kg, styrene 150Kg, B20 Polyethylene glycol surfactant 0.02Kg, α-methylstyrene 20Kg, N20 fumed silica 0.55Kg.

[0027] The specific method is as follows:

[0028] ① Put 119Kg of propylene glycol, 11Kg of ethylene glycol, 4Kg of adipic acid, 140Kg of phthalic anhydride and 54Kg of maleic anhydride into a 350L reactor in sequence.

[0029] ② Nitrogen (flow rate is 0.5m 3 / h) for 10 minutes, make the reaction kettle in a state of nitrogen blanketing, start stirring and start to heat up, keep warm for 1 hour when the temperature rises to 155-160°C, and immediately pass cooling water into the vertical condenser when the water comes out from the distillation head, and control The head temperature is 100-102°C. After the heat preservati...

Embodiment 2-6

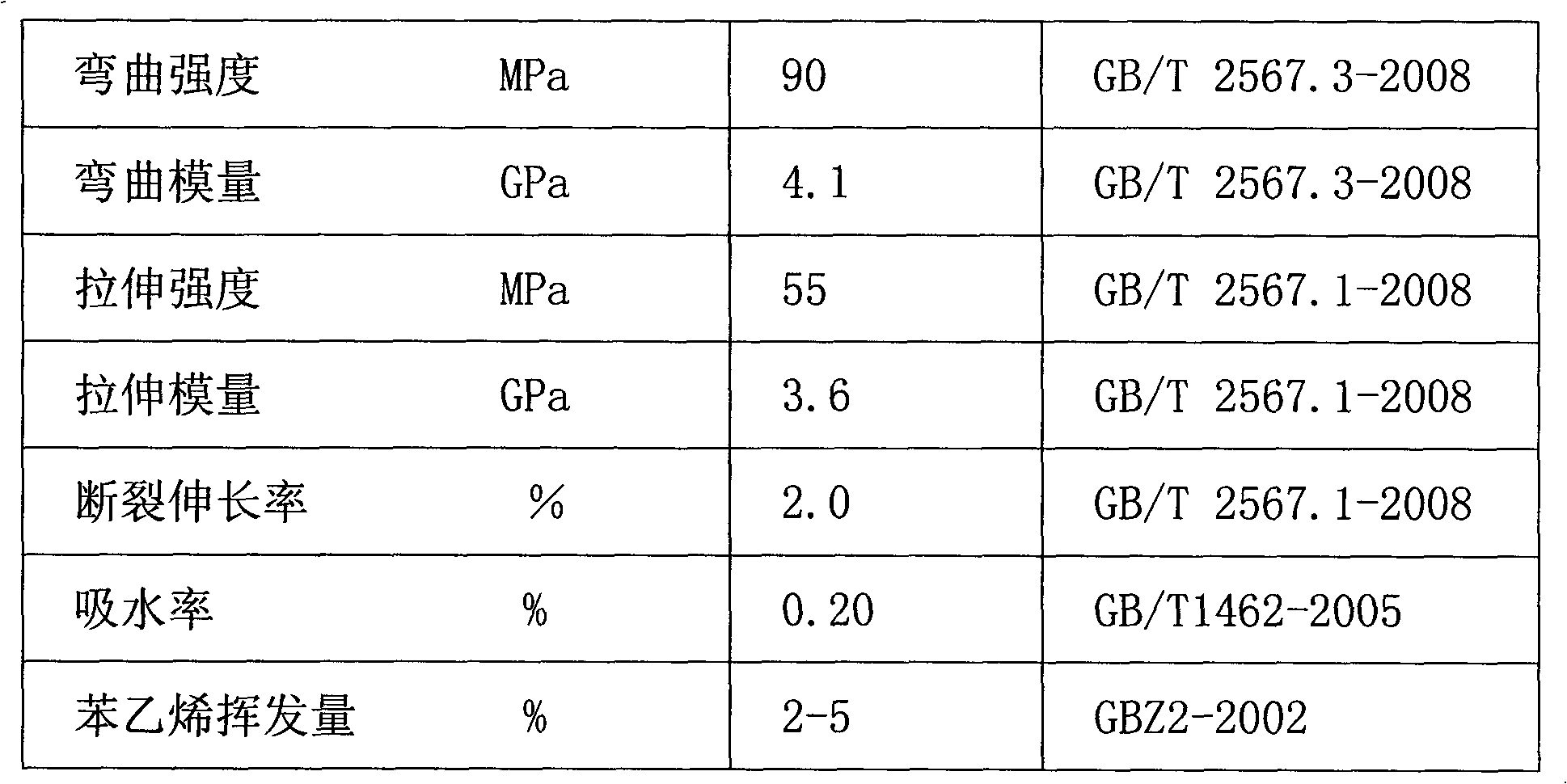

[0035]The method described in Example 1 is used to obtain a low-volatility unsaturated polyester resin suitable for large-scale FRP structural layers, and the specific raw material ester ratio is shown in Table 1. The unsaturated polyester resin was made into a casting body and its various indexes were measured, as shown in Table 1.

[0036] The formula of table 1 embodiment 1-6 and casting body index

[0037] (raw material unit Kg)

[0038] implement

example 1

implement

Example 2

implement

Example 3

implement

Example 4

implement

Example 5

implement

Example 6

119

120

119

119

112

128

Ethylene glycol

11

10

11

11

8

15

4

5

3

4

3

6

140

138

140

140

130

150

54

55

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com