Process for producing polyurethane foam

一种制造方法、氨基甲酸酯的技术,应用在半导体/固态器件制造、制造工具、研磨机床等方向,能够解决流体相聚合物组合物厚度调节、不能制造厚度精度研磨层等问题,达到研磨速度良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092] The following examples are given to illustrate the present invention, but the present invention is not limited to these examples.

[0093] [measurement, evaluation method]

[0094] (Measurement of average cell diameter, evaluation of cell shape)

[0095] The produced abrasive layer was cut in parallel with a razor blade as thin as possible to a thickness of 1 mm or less and used as a sample. The sample was fixed on a glass slide, and observed at 200 times with a SEM (S-3500N, Hitachi Science Systems Co., Ltd.). For the obtained image, the total bubble diameter in an arbitrary range was measured using an image analysis software (WinRoof, Mitani Shoji Co., Ltd.), and the average bubble diameter was calculated. Also, observe the bubble shape.

[0096] (measurement of specific gravity)

[0097] Performed in accordance with JIS Z8807-1976. Cut the manufactured abrasive layer into 4cm×8.5cm strips (thickness: optional) as a sample, and let it stand for 16 hours in an env...

Embodiment 1

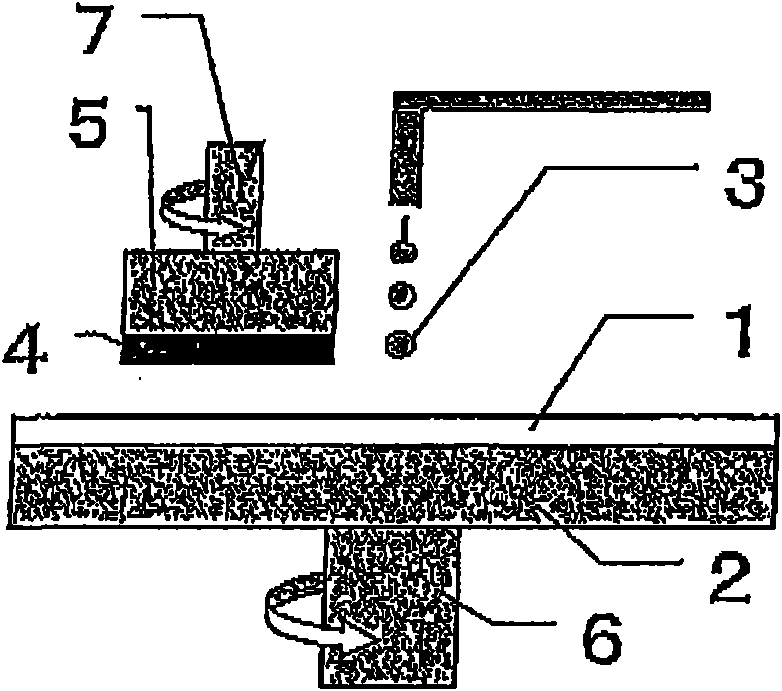

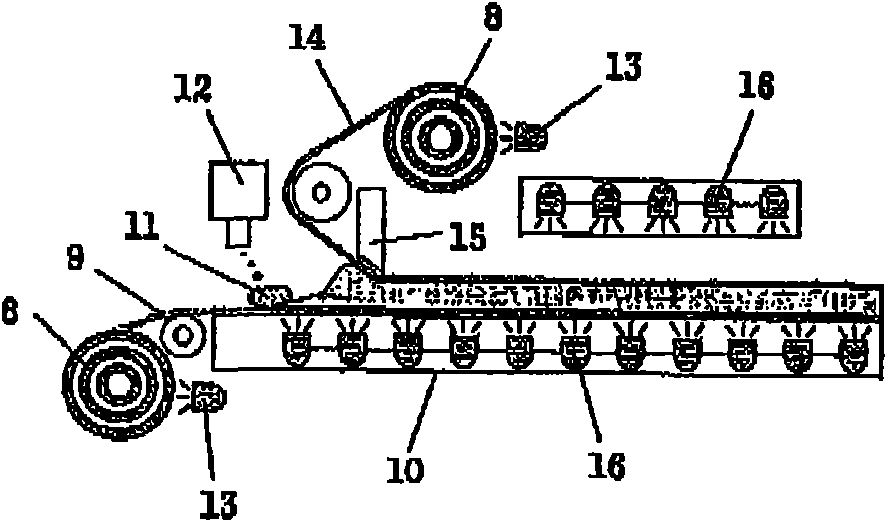

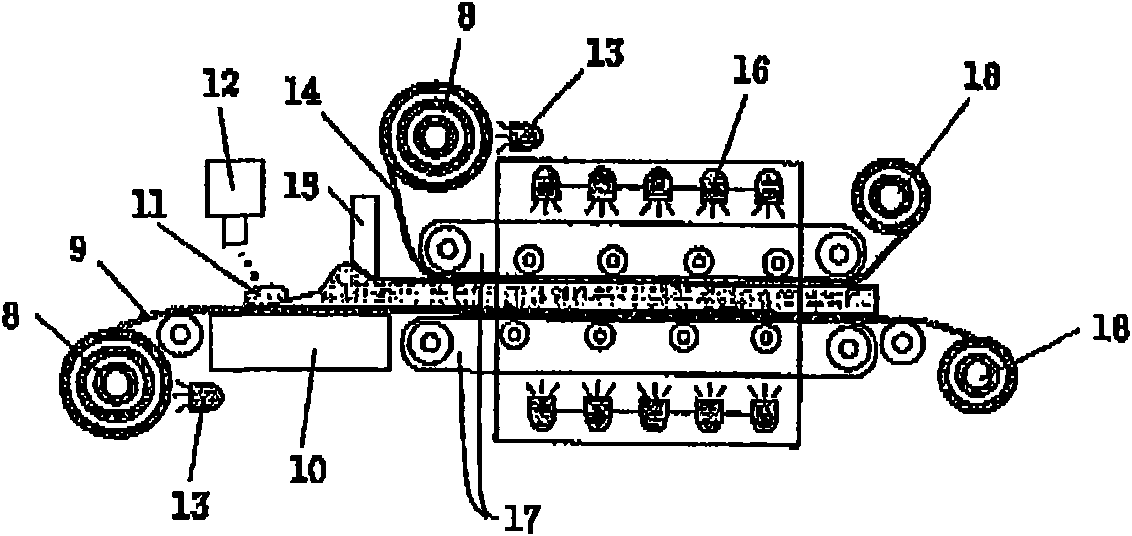

[0105] Use a heater to adjust the temperature of the surface material A (thickness 188 μm, width 100 cm) made of PET film and subjected to peeling treatment to 50 ° C and transport it to a fixed flat plate at a transport speed of 1 m / min. The discharge port continuously discharged the urethane composition (temperature at discharge: 62° C.) to the center of the surface material A in the width direction at a discharge rate of 1.2 L / min and a discharge speed of 9 m / min. Then, the surface material B (thickness 188 μm, width 100 cm) made of PET film and subjected to peeling treatment was adjusted to 50° C. with a heater and covered on the composition at a conveying speed of 1 m / min. The thickness of the composition is adjusted uniformly with a thickness adjustment interval of 20 mm and a thickness adjustment time of 1.2 seconds. Thereafter, the composition was cured by passing it through a heating oven at 70° C. installed on a fixed flat plate for 30 minutes to form a polishing she...

Embodiment 2

[0107] A polishing layer was produced in the same manner as in Example 1 except that the face materials A and B made of paper were used instead of the face materials A and B made of a PET film in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bubble diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com