Method for processing landfill percolate

A treatment method and technology of leachate, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of poor removal effect of refractory substances and high treatment cost, and achieve convenient eradication, Reduce processing costs and enhance the effect of biological reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

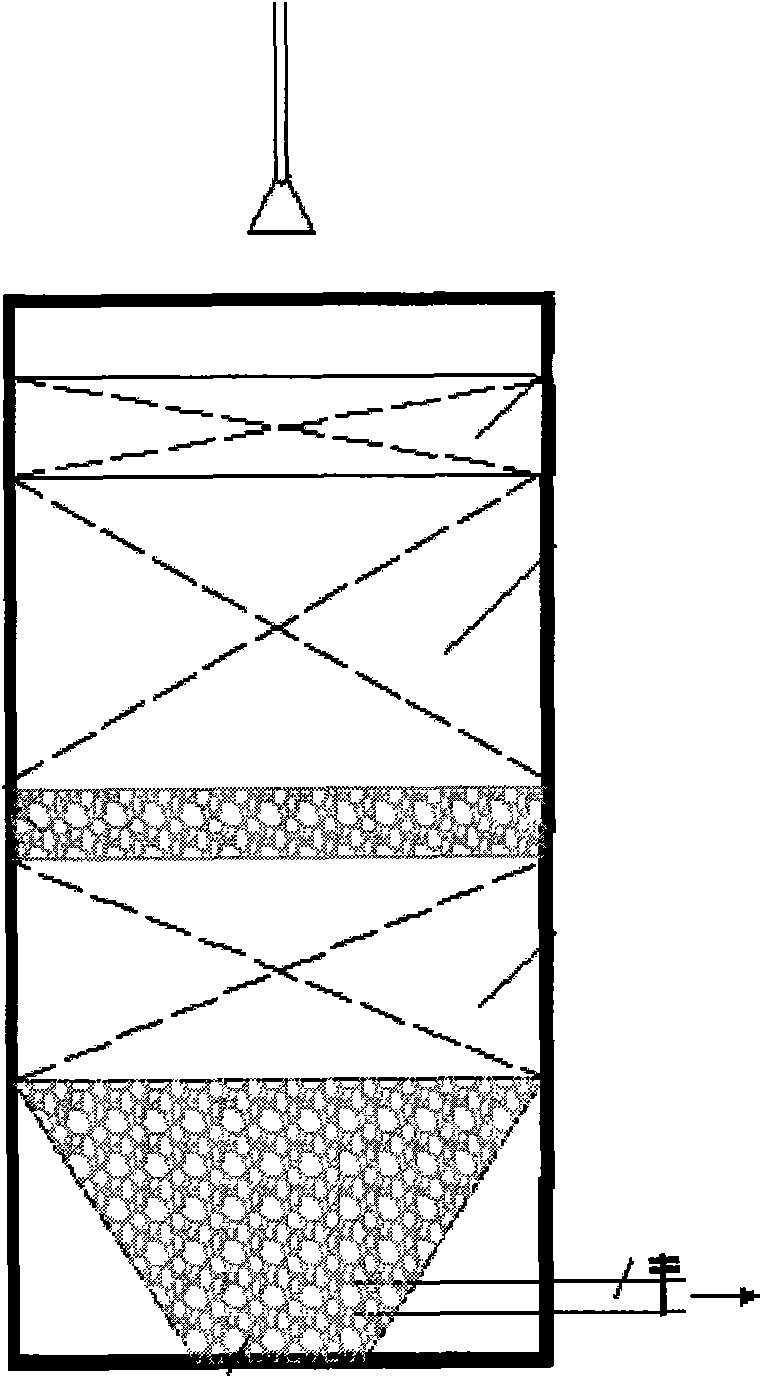

[0036] figure 1 It is a schematic diagram of a landfill leachate treatment device in the prior art. Before filtering, each filter layer is filled into a barrel, and then filtered. The landfill leachate passes through the filter layer in the barrel, and is filtered to complete the purification. The specific properties of the landfill leachate in this example are shown in Table 1, and the specific properties of the mineralized waste used to build the bed are shown in Table 2.

[0037] Table 1 Influent water quality index (mg / L)

[0038] Exterior

[0039] Table 2 Basic properties of mineralized waste (landfill age 8 years, sieving particle size ≤ 40mm)

[0040] nature

[0041] Construct the bio-iron internal electrolysis reaction bed with Fe and mineralized waste (referring to the sum of the mineralized waste mass of each layer in the barrel) with a mass ratio of 1:20; the bottom of the iron filings layer is provided with a water-permeable support plate to ...

Embodiment 2

[0043] A PVC column with an inner diameter of 10 cm and a height of 1.0 m was used, and each filter layer was filled therein. Wherein the reaction bed body consists of a 5cm high crushed stone support layer, a main reaction layer (wherein the main reaction layer of the reaction bed is composed of mineralized garbage and corresponding scrap iron chips in a mass ratio of 10:1, and the Fe layer is on top of the mineralized garbage layer at the bottom) and 5cm super high; the bottom of the iron filings layer is provided with a water-permeable support plate, and holes with a diameter of 10mm are distributed on the support plate; the particle size of the mineralized waste is 40-60mm, and it will be buried for 10 years. The scrap iron chips used come from the broken iron pieces cut by the lathe when the alloy steel parts are processed in the metal machinery processing factory. The iron chips are about 4mm wide and 1mm thick and in a curled shape. Before use, soak them in 1% hydrochlor...

Embodiment 3

[0051] The specific properties of landfill leachate are shown in Table 5.

[0052] Table 5 Influent water quality index (mg / L)

[0053] COD Cr

pH

TOC

TN

tertiary water

701

7.47

10010

135

398.9

510.8

[0054] Note: The unit of conductivity is (μs / cm); pH has no unit, and the other indicators are mg / L.

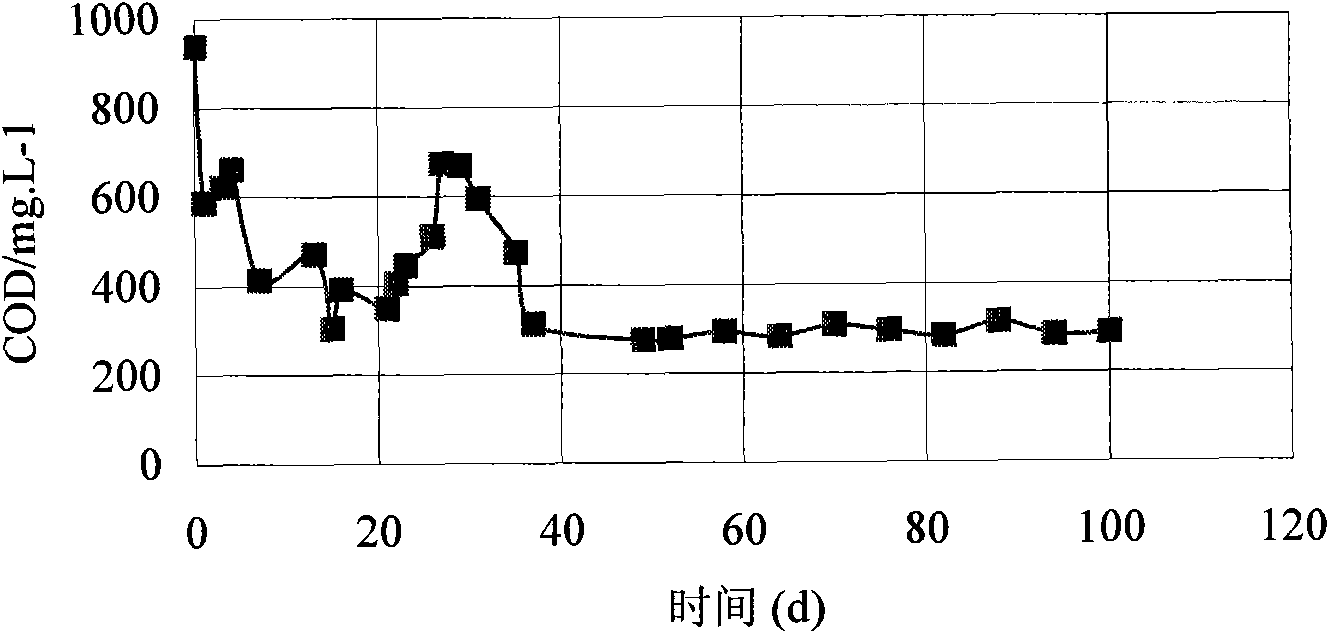

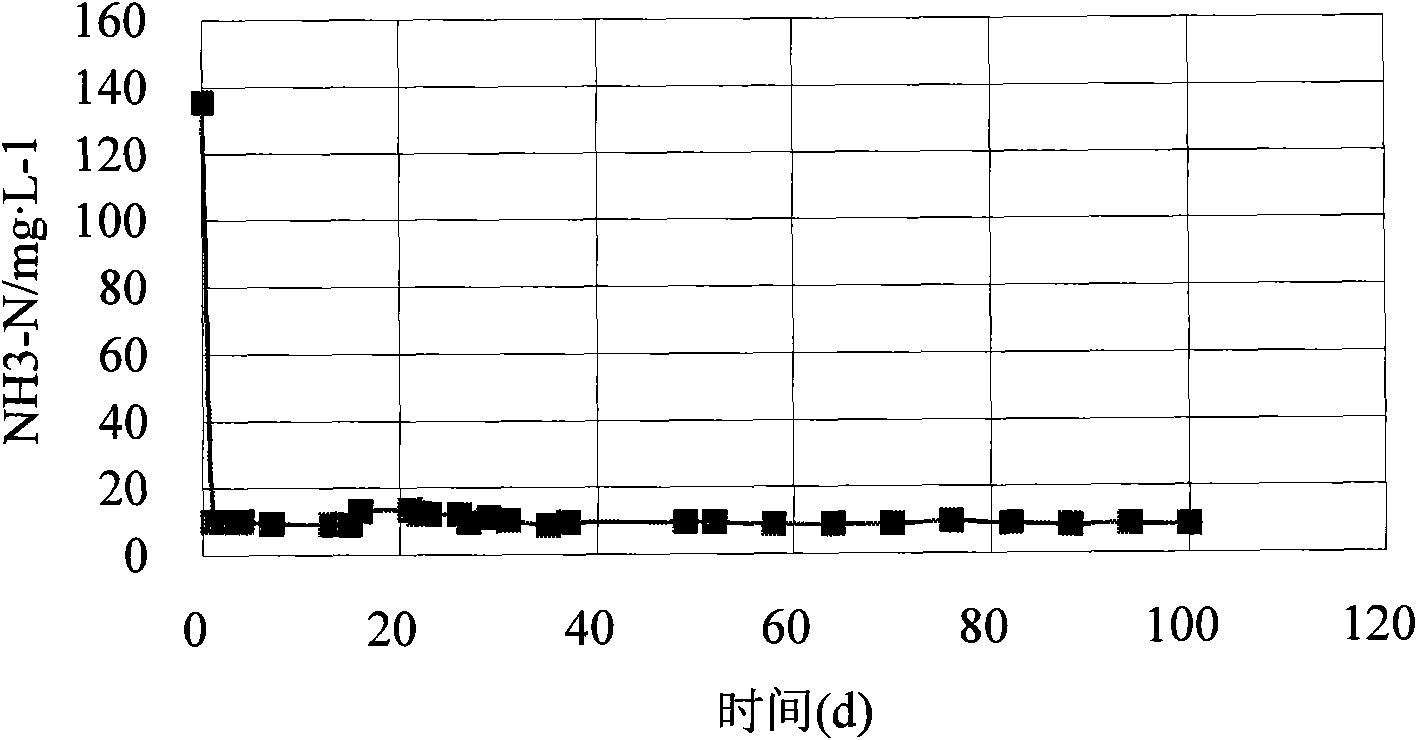

[0055] In this implementation, the quality of the iron filings layer is 510g, and the quality of the mineralized garbage layer (the sum of the mineralized garbage quality of each layer in the barrel body) is 4.65Kg; the size of the iron flakes in the used iron filings is: 0 Figure 6 It can be seen from the figure that after being treated by the bio-iron internal electrolytic reaction bed, the COD of the secondary water Cr It can be reduced from 701mg / L to below 300mg / L, reaching the second level index of national effluent, reflecting a strong processing capacity. Fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com