Method and apparatus for supplying and recycling oxygen in process of high-density fermentation of aerobic microorganism

An aerobic microorganism and high-density fermentation technology, applied in the field of fermentation engineering, can solve the problems of reduced oxygen utilization, cannot be utilized by microorganisms, and increased cost, and achieves the effects of increasing solubility, shortening aerobic fermentation cycle, and improving productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Synthesis of polyhydroxybutyrate by high-density aerobic fermentation of Ralstonia eutropha in a 5-liter fermenter

[0026] Strain: Ralstonia eutropha NCIMB 11599 was purchased from the British Culture Collection

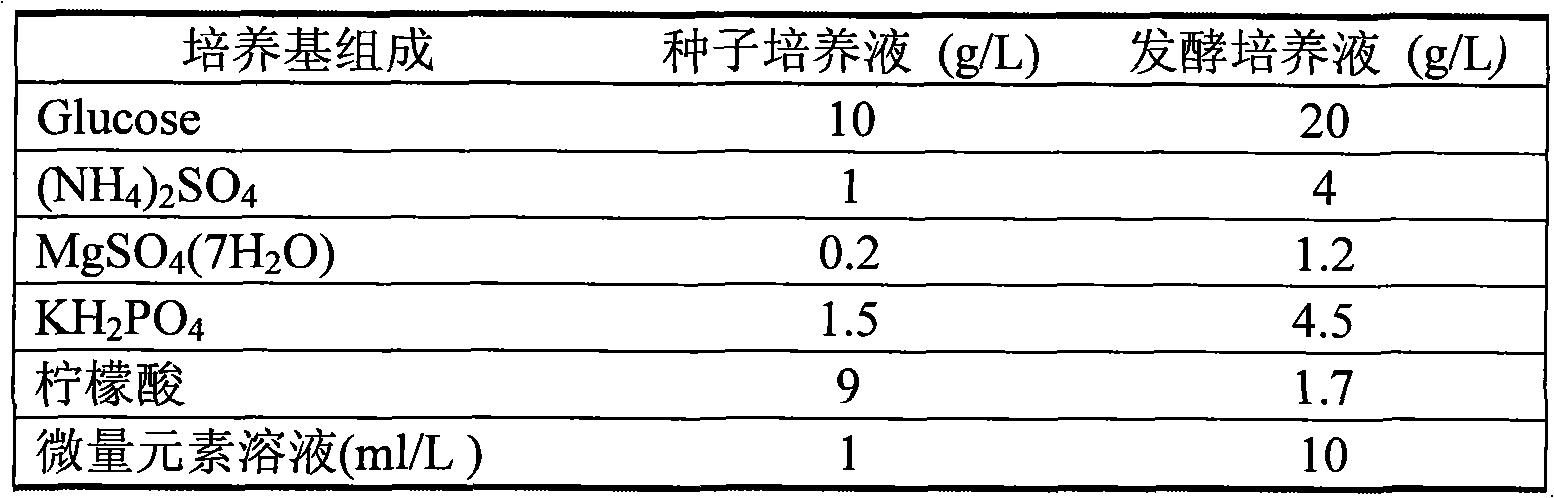

[0027] Culture medium composition: the composition of seed culture liquid and fermented liquid is as follows:

[0028]

[0029] Attachment: The trace element solution contains 10g FeSO per liter 4 (7H 2 O), 2.25g ZnSO 4 (7H 2 O), 1.2g CuSO4(5H 2 O), 0.5g MnSO 4 (5H 2 O), 2g CaCl 2 (2H 2 O), 0.25g Na 2 B 4 o 7 (7H 2 O), 0.12g (NH 4 )6Mo 7 o 24 , and 10ml of 35% HCl.

[0030] Analysis and test method: take out 2 ml of fermentation broth during the fermentation process, after centrifugation, washing, and centrifugation again, dry the cells to constant weight at 105°C, weigh them to calculate the cell concentration: dry cell weight / per liter of fermentation broth. The concentration of the metabolite polyhydroxybutyrate (PHB) was meas...

Embodiment 2

[0035] Example 2 Synthesis of polyhydroxybutyrate by high-density aerobic fermentation of Ralstonia eutropha in a 30-liter fermenter

[0036] Adopt the bacterial classification identical with embodiment 1, culture medium composition, analytical test method and process control method, obtain following result in 30 liters of fermentors:

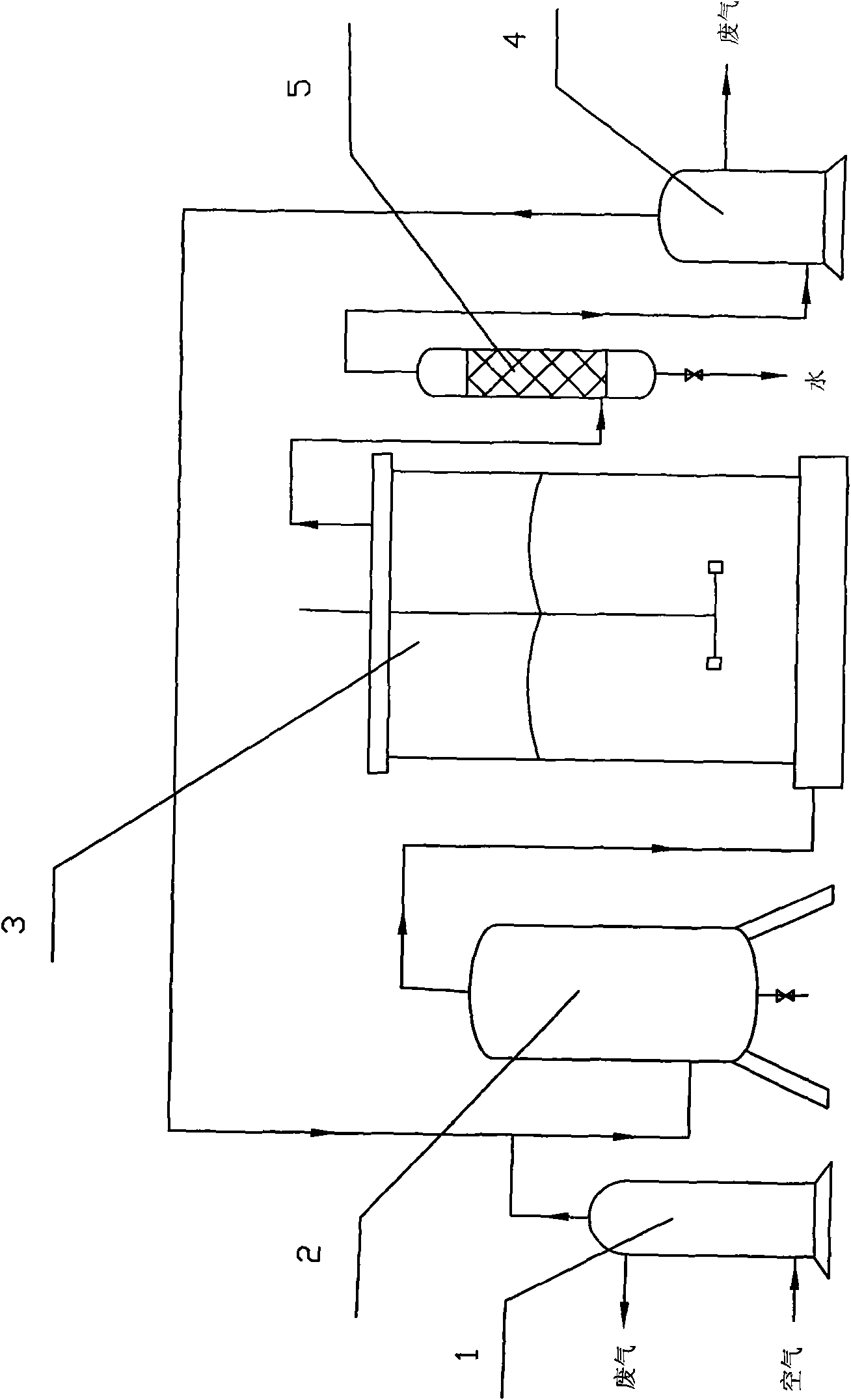

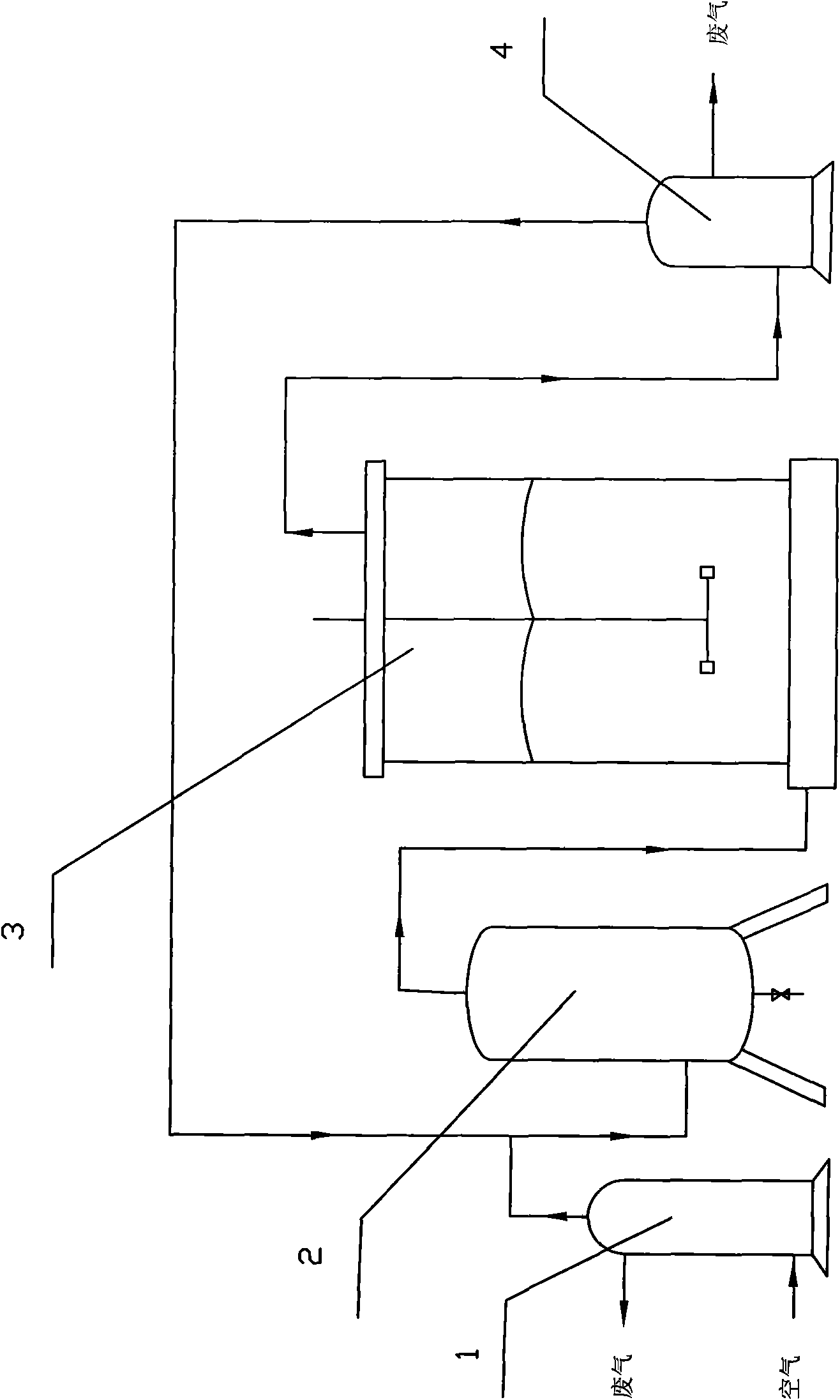

[0037] As the volume of the fermentation tank increases, the number of microorganisms in the tank increases, requiring more oxygen to meet the needs of the growth of aerobic microorganisms and the metabolism and synthesis of products; Ester is carried out in 30 liters fermentors, keeps other all operating conditions identical with embodiment 1, but the gas that fermentor 3 gas outlets discharges is sent into moisture separator 5 earlier, then enters second oxygen generator II4; Utilize Oxygen supply and recycling method in the high-density fermentation process of aerobic microorganisms, the final cell concentration and product concentration are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com