Technology for treating and reusing sewerages of industrial circulating water

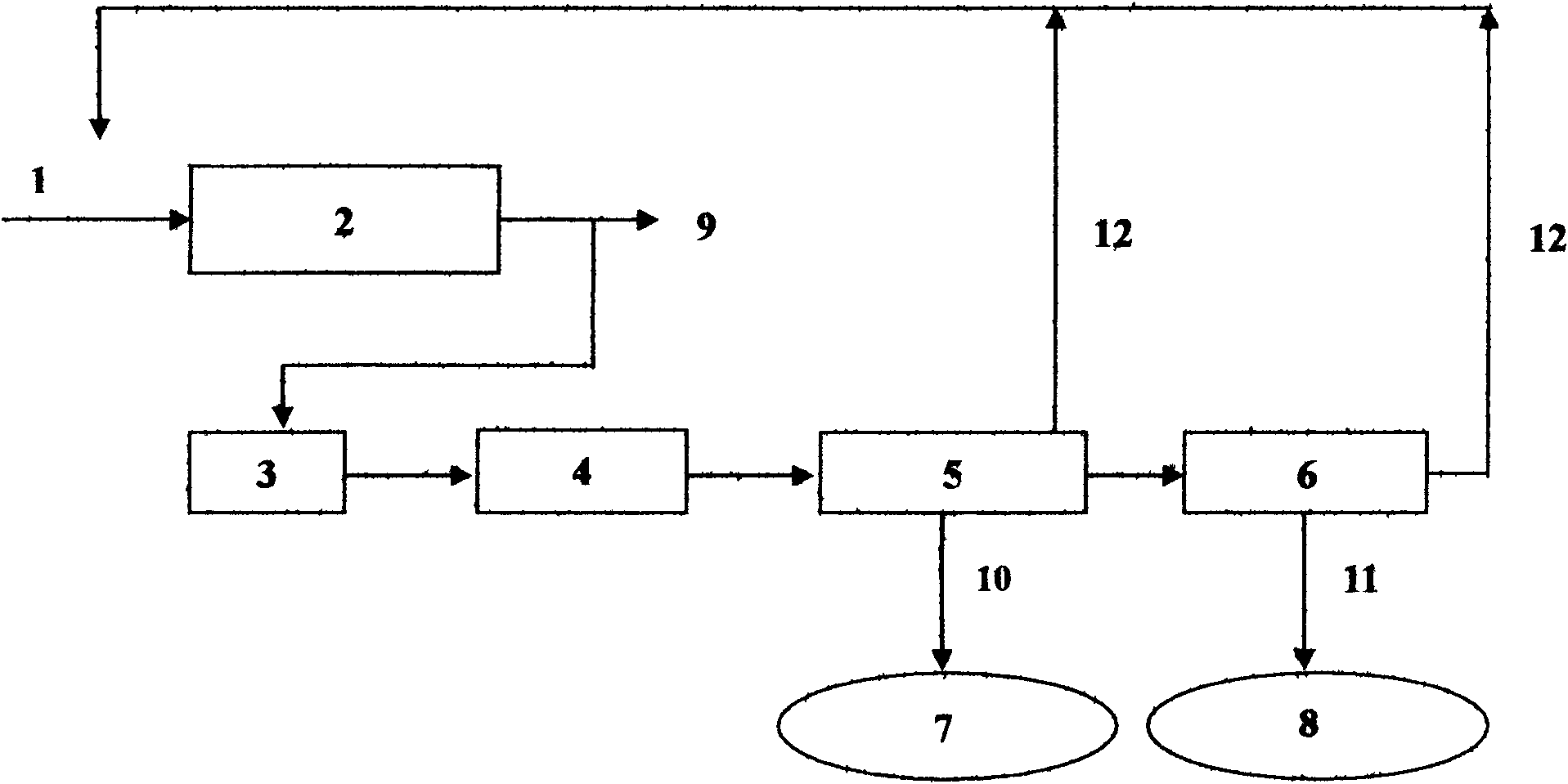

A technology for industrial circulating water and sewage, which is applied in the direction of adsorption water/sewage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problem of large cooling water side-flow treatment, acid-base consumption, poor treatment effect, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The water sample is taken from a chemical fertilizer plant that uses natural gas as raw material. The circulating water and sewage are directly passed through the photocatalytic oxidation reactor according to step A. The light source is an ultraviolet lamp system, and the photocatalytic material is 1% ammonium molybdate and 1% nickel nitrate , and 1% cobalt nitrate composite loaded titanium dioxide catalyst. The light source part adopts a multi-stage parallel arrangement. The influent COD concentration dropped from 258mg / L to 38mg / L, and the TOC dropped from 80mg / L to 8mg / L. The discharged water meets the first class a standard of urban sewage treatment plant pollutant discharge (GB 18918-2002).

Embodiment 1 proportion 1

[0017] The photocatalytic material uses ordinary titanium dioxide as a catalyst. The light source part adopts a multi-stage parallel arrangement. The concentration of influent COD dropped from 258mg / L to 163mg / L, and TOC dropped from 80mg / L to 54mg / L. The discharged water cannot meet the first class a standard of urban sewage treatment plant pollutant discharge (GB 18918-2002).

Embodiment 1 proportion 2

[0019] The photocatalytic material uses 0.5% ammonium molybdate supported on titanium dioxide as a catalyst. The light source part adopts a multi-stage parallel arrangement. The concentration of influent COD dropped from 272mg / L to 113mg / L, and TOC dropped from 83mg / L to 26mg / L. The discharged water cannot meet the first class a standard of urban sewage treatment plant pollutant discharge (GB 18918-2002).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com