Method for extracting soybean dietary fibre and soybean protein from soybean residue

A technology of soybean dietary fiber and soybean protein, which is applied in plant protein processing, protein food ingredients, protein composition of vegetable seeds, etc., to achieve the effects of short process, overcoming equipment corrosion, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

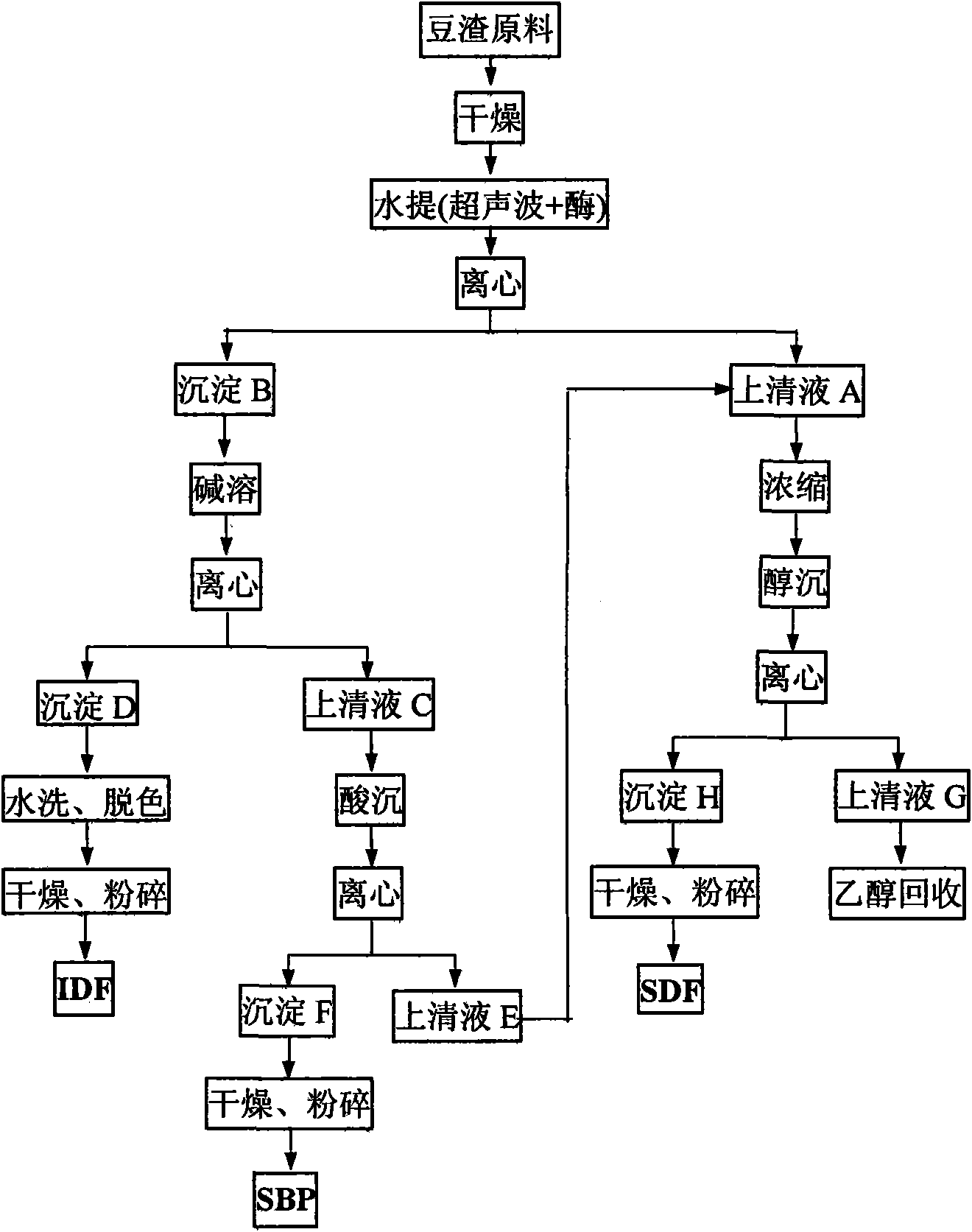

Image

Examples

Embodiment 1

[0022] The method for extracting soybean dietary fiber and soybean protein from bean dregs comprises the following steps:

[0023] step 1

[0024] Dry the fresh bean dregs at 50-60°C to constant weight, pulverize them, and pass through a 80-mesh sieve to obtain bean dregs powder;

[0025] step 2

[0026] Weigh 10g of bean dregs powder, add 495mL water extract and 7.4mL cellulase solution (enzyme activity is 0.22U / mL), stir well and put it into an ultrasonic extractor. Ultrasonic extraction for 20 minutes under the condition of empty ratio 1:0.5 to obtain ultrasonic extraction solution;

[0027] The above water extract contains cellulase with an enzyme activity of 0.22-3.14U / mL, and the enzyme activity of cellulase is defined as the hydrolysis of sodium carboxymethylcellulose substrate within 1 minute to generate 1umol under the conditions of 37°C and pH 7.0 The enzyme amount of glucose is one enzyme activity unit (U).

[0028] step 3

[0029] The ultrasonic extract was ce...

Embodiment 2

[0036] In step 4, citric acid was added to supernatant C to adjust its pH to 4.5.

[0037] Other steps are the same as in Example 1.

Embodiment 3

[0039] In step 4, malic acid was added to supernatant C to adjust its pH to 4.5.

[0040] Other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com