Method for preparing molecular imprinted polymer for recognizing chloromycetin, thiamphenicol and florfenicol simultaneously

The technology of fluorine thiamphenicol and thiamphenicol is applied in the field of preparation of molecularly imprinted polymers, and can solve the problems affecting the wide application of molecularly imprinted solid-phase extraction technology, removing template molecules from polymers, and leakage of template molecules, etc. Achieve the effect of large promotion and application value, improve detection sensitivity and detection efficiency, and strong identification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

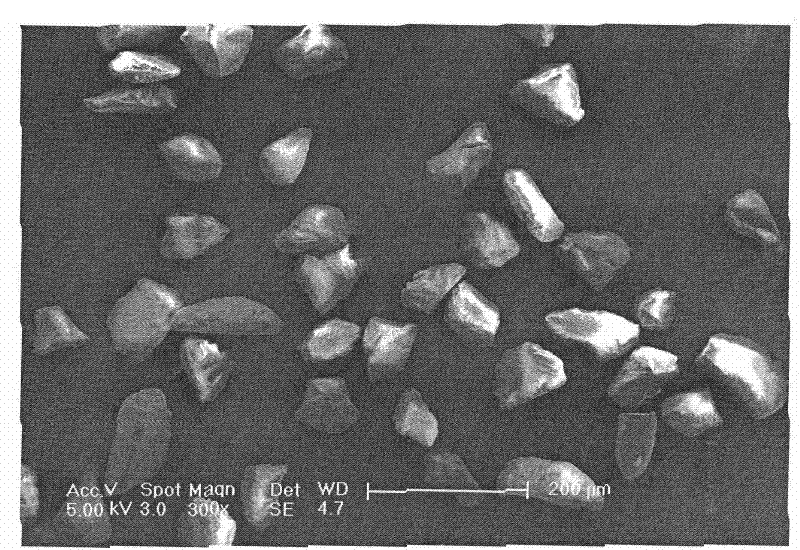

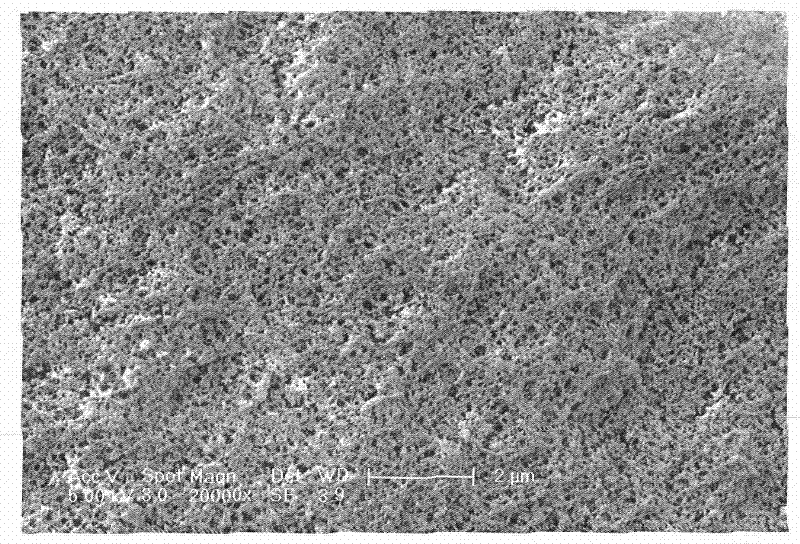

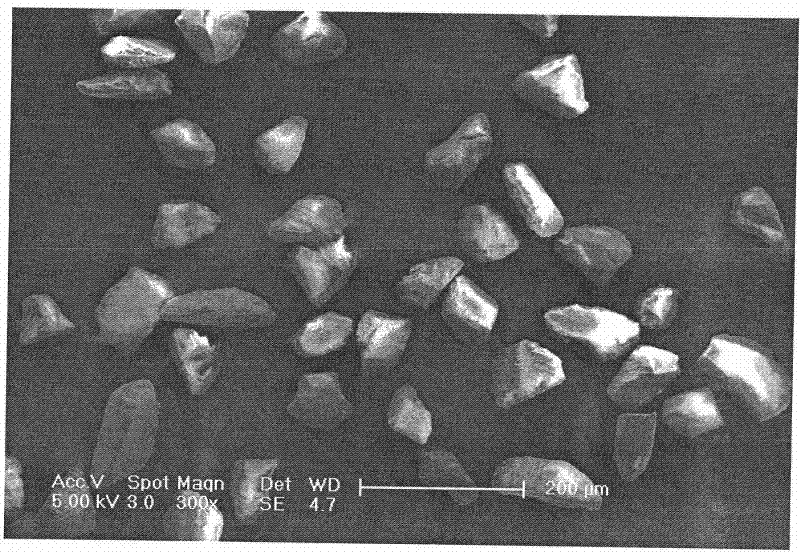

Embodiment 1

[0021] Add 1 mmol of functional monomer methacrylic acid (MAA) to 5 ml of porogen acetonitrile, add 25 mmol of cross-linking agent ethylene glycol dimethacrylate (EGDMA), mix well, heat at 40°C for 2 min, and then add template molecules 1 mmol of thiamphenicol was passed through nitrogen for 10-15 minutes, the initiator azobisisobutyronitrile (AIBN) was added, ultrasonic degassed for 5-10 minutes, and sealed under nitrogen or vacuum state. React at 60°C for 36 hours; after the polymerization reaction, take out the synthesized polymer, grind it, sieve it, and use methanol: formic acid (v / v 9 / 1), methanol to remove the template molecule through Soxhlet extraction, and further extract the obtained molecule The imprinted polymer was loaded into a solid-phase extraction column, rinsed with methanol: formic acid (v / v9 / 1) and methanol in sequence, and detected by high-performance liquid chromatography-mass spectrometry until no template molecules were detected; The polymer is vacuum-...

Embodiment 2

[0023] Add 8mmol of functional monomer methacrylic acid (MAA) to 5ml of porogen acetonitrile, add 25mmol of cross-linking agent ethylene glycol dimethacrylate (EGDMA), mix well, heat at 50°C for 2min, and then add template molecules 1 mmol of thiamphenicol was passed through nitrogen for 10-15 minutes, the initiator azobisisobutyronitrile (AIBN) was added, ultrasonic degassed for 5-10 minutes, and sealed under nitrogen or vacuum state. React at 60°C for 36 hours; after the polymerization reaction, take out the synthesized polymer, grind it, sieve it, and use methanol: formic acid (v / v 9 / 1), methanol to remove the template molecule through Soxhlet extraction, and further extract the obtained molecule The imprinted polymer was loaded into a solid-phase extraction column, rinsed with methanol: formic acid (v / v9 / 1) and methanol in sequence, and detected by high-performance liquid chromatography-mass spectrometry until no template molecules were detected; The polymer is vacuum-drie...

Embodiment 3

[0025] Add 1 mmol of functional monomer N, N-diethylaminoethyl methacrylate (DEAEM) to 5 ml of porogen acetonitrile, add 25 mmol of crosslinking agent ethylene glycol dimethacrylate (EGDMA), and mix well , heat at 40°C for 2 minutes, then add 1 mmol of the template molecule thiamphenicol, pass through nitrogen for 10 to 15 minutes, add the initiator azobisisobutyronitrile (AIBN), ultrasonically degas for 5 to 10 minutes, and seal under nitrogen or vacuum state . Reaction at 70°C for 36h; after the polymerization reaction, the synthesized polymer was taken out, ground, sieved, and template molecules were removed by Soxhlet extraction with methanol: formic acid (v / v 9 / 1), methanol, and the obtained molecules were further The imprinted polymer was loaded into a solid-phase extraction column, rinsed with methanol: formic acid (v / v 9 / 1), and methanol in sequence, and detected by high-performance liquid chromatography-mass spectrometry until no template molecules were detected; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com