Terylene FDY spinning oil and preparation process thereof

A spinning oil and polyester technology, which is applied in the field of polyester FDY spinning oil and its manufacturing, can solve the problems of oil mist pollution and easy volatilization of chemical fiber oil, and achieve stable quality, good bundling, and even fiber oil content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

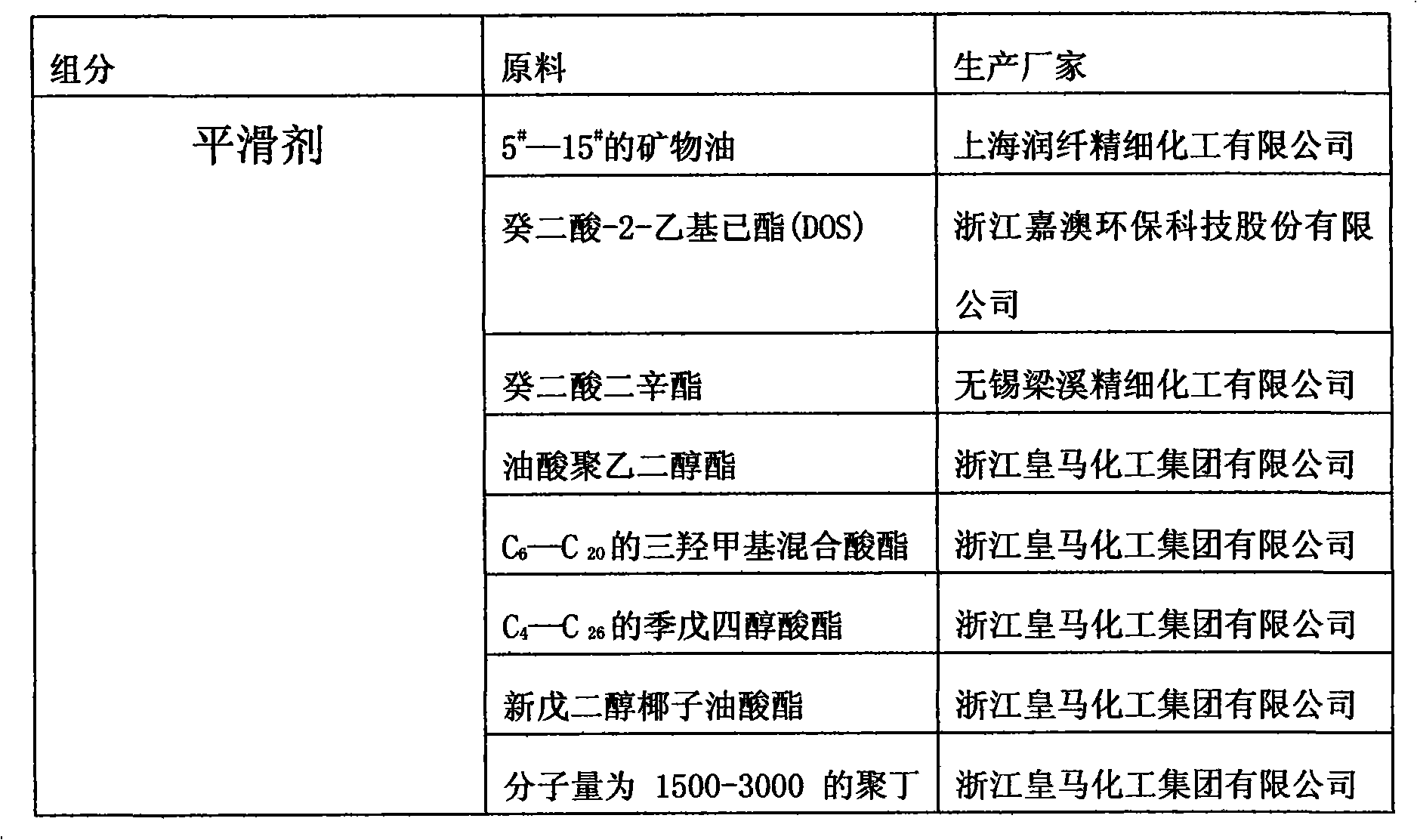

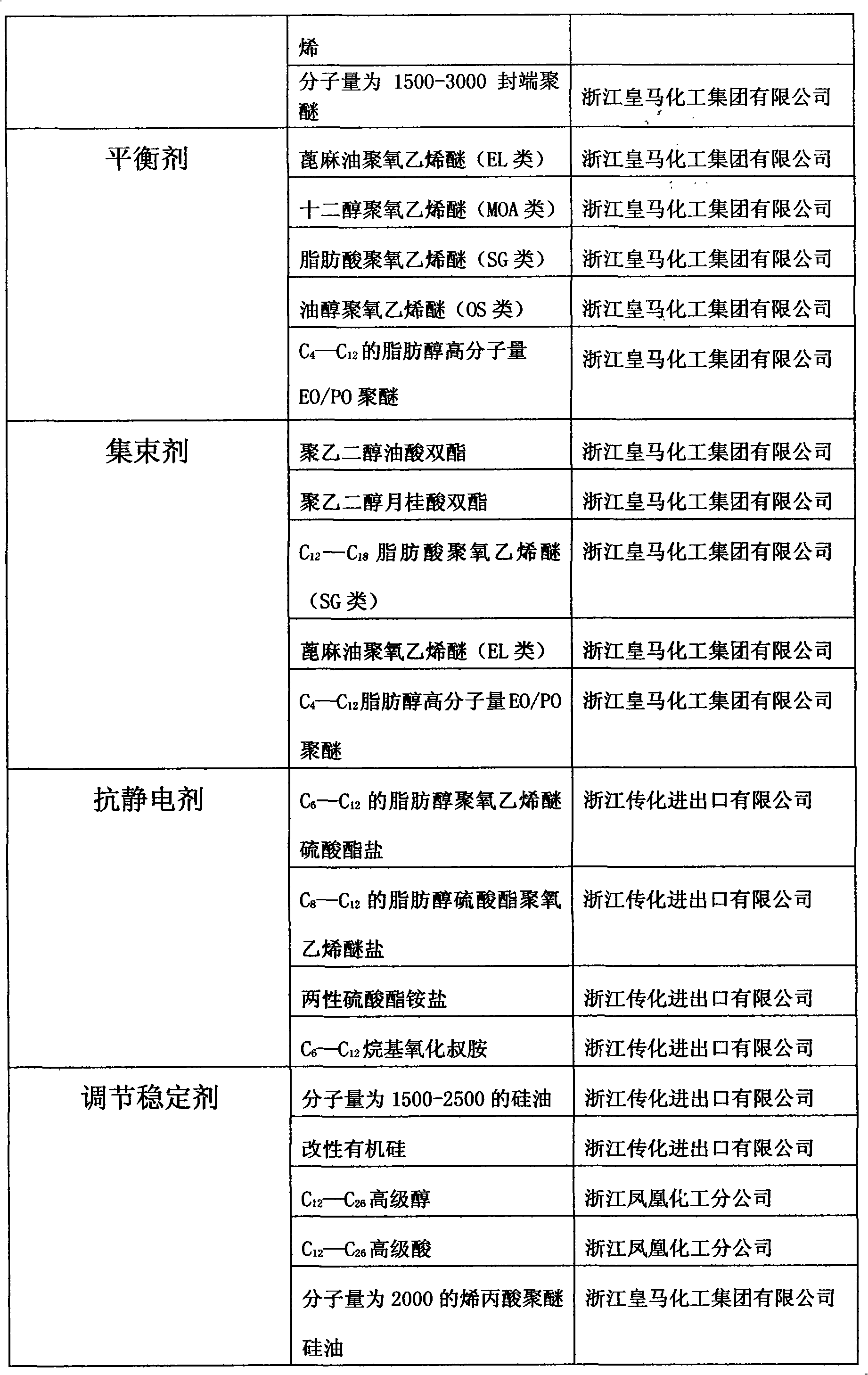

Method used

Image

Examples

Embodiment 1

[0021] The present embodiment determines that the ratio of each component is by weight percentage;

[0022] Balancer 25%, lauryl alcohol polyoxyethylene ether (MOA type) 8%, oleyl alcohol polyoxyethylene ether (OS type) 17%;

[0023] 10% sizing agent, 5% polyethylene glycol (400) diester oleate, 5% polyethylene glycol (800) diester laurate;

[0024] Antistatic agent 5%, fatty alcohol (C 6~12 ) Polyoxyethylene ether sulfate ester salt 4%, amphoteric sulfate ester ammonium salt 1%;

[0025] Smoothing agent 58%, mineral oil (15 # ) 35%, 2-ethylhexyl sebacate (DOS) 23%;

[0026] Adjust stabilizer 2%, silicone oil 2%.

[0027] After batching according to the above ratio, the manufacturing method of its polyester FDY spinning finish is:

[0028] Pump the balancing agent, clustering agent, and antistatic agent into the reactor, start stirring, raise the temperature to about 50°C, stir evenly, then pump the smoothing agent into the reactor, keep the temperature at about 50°C, sti...

Embodiment 2

[0030] The present embodiment determines that the ratio of each component is by weight percentage;

[0031] Balancer 20%, including fatty alcohol high molecular weight EO / PO polyether (molecular weight 5000) 5%, castor oil polyoxyethylene ether (EL type) 8%, fatty acid polyoxyethylene ether (SG type) 7%;

[0032] Stimulant 12%, castor oil polyoxyethylene ether 5%, lauric acid polyethylene glycol (400) diester 7%;

[0033] Antistatic agent 5%, of which fatty alcohol (C 8-12 ) sulfate polyoxyethylene ether salt 1%, fatty alcohol (C 8-12 ) polyoxyethylene ether sulfate 4%;

[0034] Smoothing agent 60%, of which mineral oil (5 # )15%, trimethylol mixed acid (C 6~20 ) ester 30%, capped polyether (molecular weight 3000) 15%;

[0035] Adjusting stabilizer 3%, of which modified silicone 2%, advanced acid (C 26 )1%.

[0036] After batching according to the above ratio, the manufacturing method of its polyester FDY spinning finish is:

[0037] Pump the balancing agent, clusterin...

Embodiment 3

[0039] The present embodiment determines that the ratio of each component is by weight percentage;

[0040] Balancer 20%, of which oleyl alcohol polyoxyethylene ether 12%, fatty alcohol (C 4-12 ) High molecular weight EO / PO polyether (molecular weight 5000) 5%, lauryl alcohol polyoxyethylene ether (MOA type) 3%;

[0041] Stimulant 10%, castor oil polyoxyethylene ether (EL type) 5%, fatty acid (C 12-18 ) polyoxyethylene ether (SG type) 5%;

[0042] Antistatic agent 7%, of which fatty alcohol (C 10-18 ) polyoxyethylene ether sulfate 4%, C 6 -C 12 Alkyl tertiary amine oxide 3%;

[0043] Smoothing agent 61%, of which pentaerythritol (C 4~26 ) acid ester 20%, polybutene (molecular weight 2500) 15%, neopentyl glycol cocoate 26%;

[0044] Conditioning stabilizer: silicone oil 2%.

[0045]After proportioning according to the ratio described in above-mentioned three embodiments, the manufacture method of its polyester FDY spinning finish is:

[0046] Pump the balancing agent, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com