Drying method and drying equipment of wet rice paper poster

A technology of drying equipment and drying method, which is applied to dryers for static materials, drying solid materials, lighting and heating equipment, etc. The effect of rice paper yield, reducing environmental pollution and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

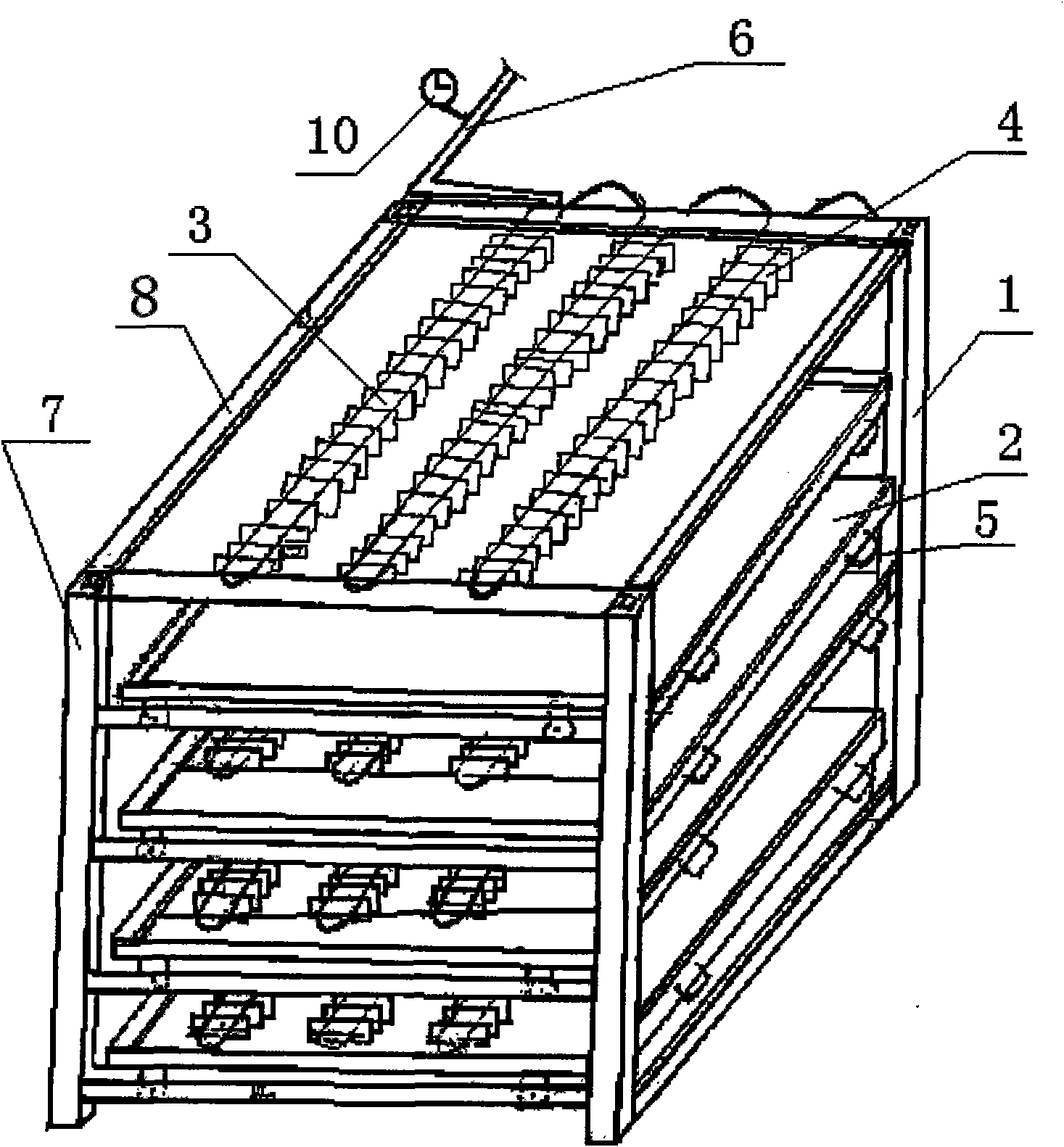

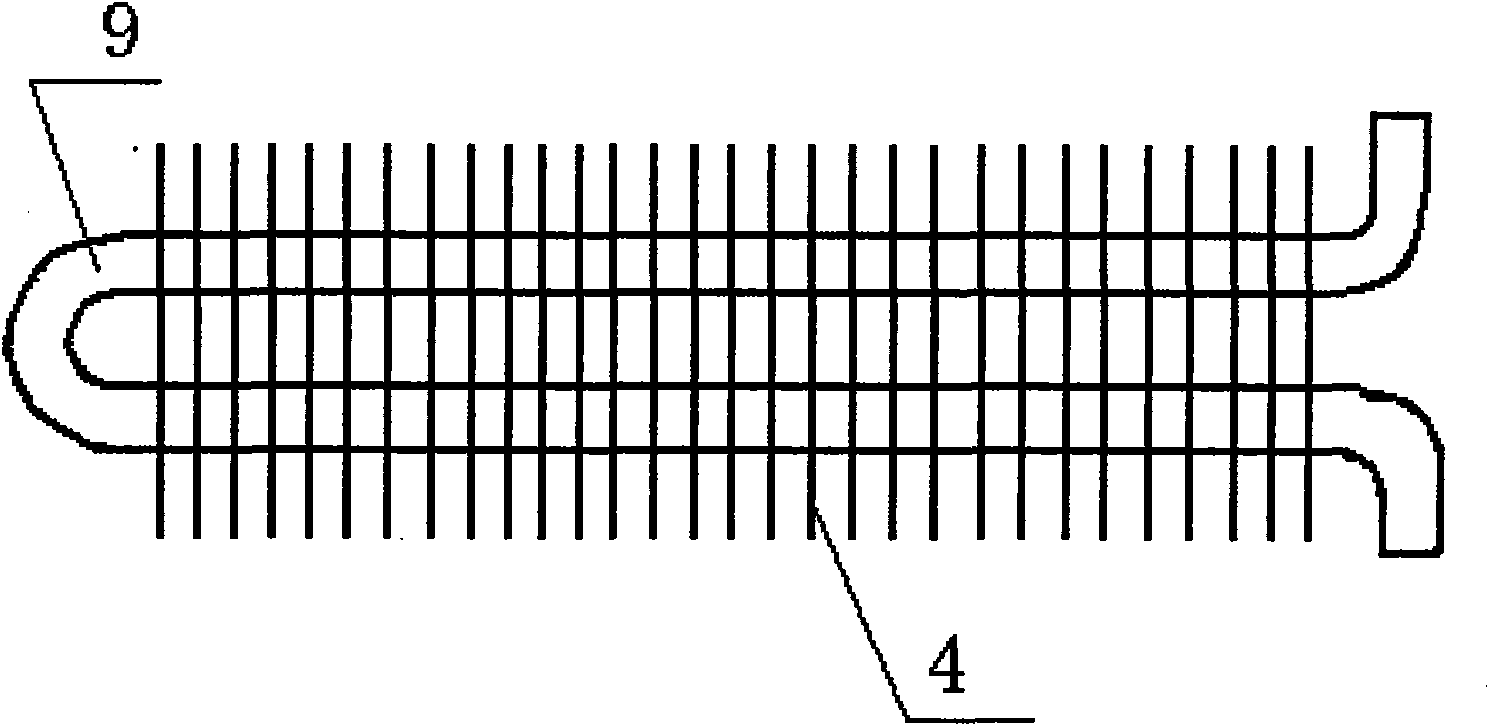

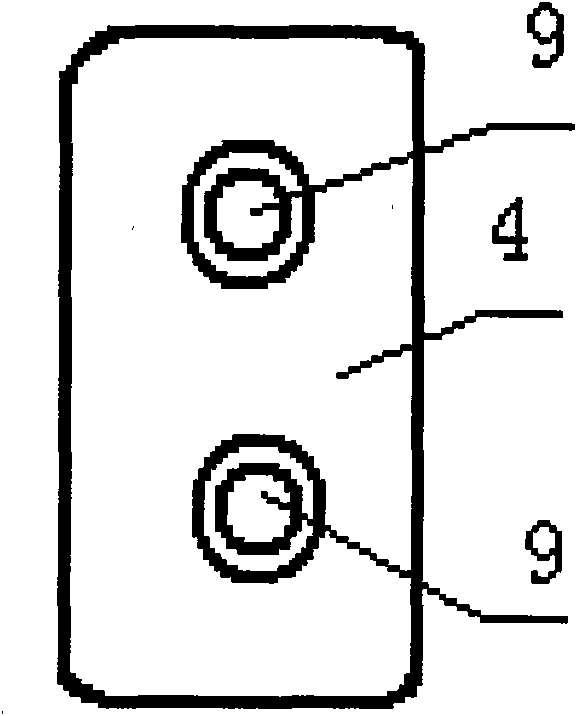

[0026] figure 1 It is a structural schematic diagram of a kind of rice paper wet paste drying machine of the present utility model; figure 2 It is a structural schematic diagram of a heat transfer device of a rice paper wet paste dryer of the present invention; image 3 It is a schematic diagram of the heat sink of a rice paper wet paste dryer of the present invention; it includes a frame 1, a heat transfer device 3 and a temperature control device, the frame 1 is a frame structure composed of a pillar 7 and a crossbeam 8, and the temperature control device controls heat transfer The device 3 transfers heat outward, and the frame 1 is divided into multi-layer shelf parts by beams 8. A heat transfer device 3 is arranged between each interval of the shelf parts, and a rice paper wet sticker can be placed between adjacent heat transfer devices 3. The bracket 2 of the rice paper wet post bracket 2 is provided with a rolling bearing that drives the rice paper wet post bracket to ...

Embodiment 2

[0033] The equipment is the same as in Example 1, and the wet paste steps of dry rice paper are as follows:

[0034] (1) Preheating stage: time 90 minutes, rising from room temperature to 76°C;

[0035] (2) Constant-speed drying stage: time 480 minutes, temperature 76°C;

[0036] (3) Cooling and drying stage: the time is 200 to 210 minutes, the temperature drops from 76°C to 45°C; the temperature control allows plus or minus 3°C.

Embodiment 3

[0038] The equipment is the same as in Example 1, and the wet paste steps of dry rice paper are as follows:

[0039] (1) Preheating stage: time 2 hours, from room temperature to 80°C;

[0040] (2) Constant-speed drying stage: time 9 hours, temperature 76°C;

[0041] (3) Cooling and drying stage: the time is 4 hours, the temperature is lowered from 80°C to 50°C; the temperature control allows plus or minus 3°C.

[0042] Adopting the above-mentioned technical scheme, the performance is reliable, the operation is simple, and has the following beneficial effects:

[0043] 1. Save energy

[0044] 640m2 drying room for original soil baking tray 2 , the annual coal consumption is more than 1300 tons, and the steam production is 5200T / year. Using the disc dryer, the annual coal consumption is reduced to 600 tons, and the steam consumption is 2400T / year.

[0045] 2. Environmental governance

[0046] The weight of toxic gas emitted by burning coal per ton is 60kg of sulfur dioxide, 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com