Exhaust gas catalysts and exhaust-gas catalytic converter

A technology of catalysts and catalyst carriers, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

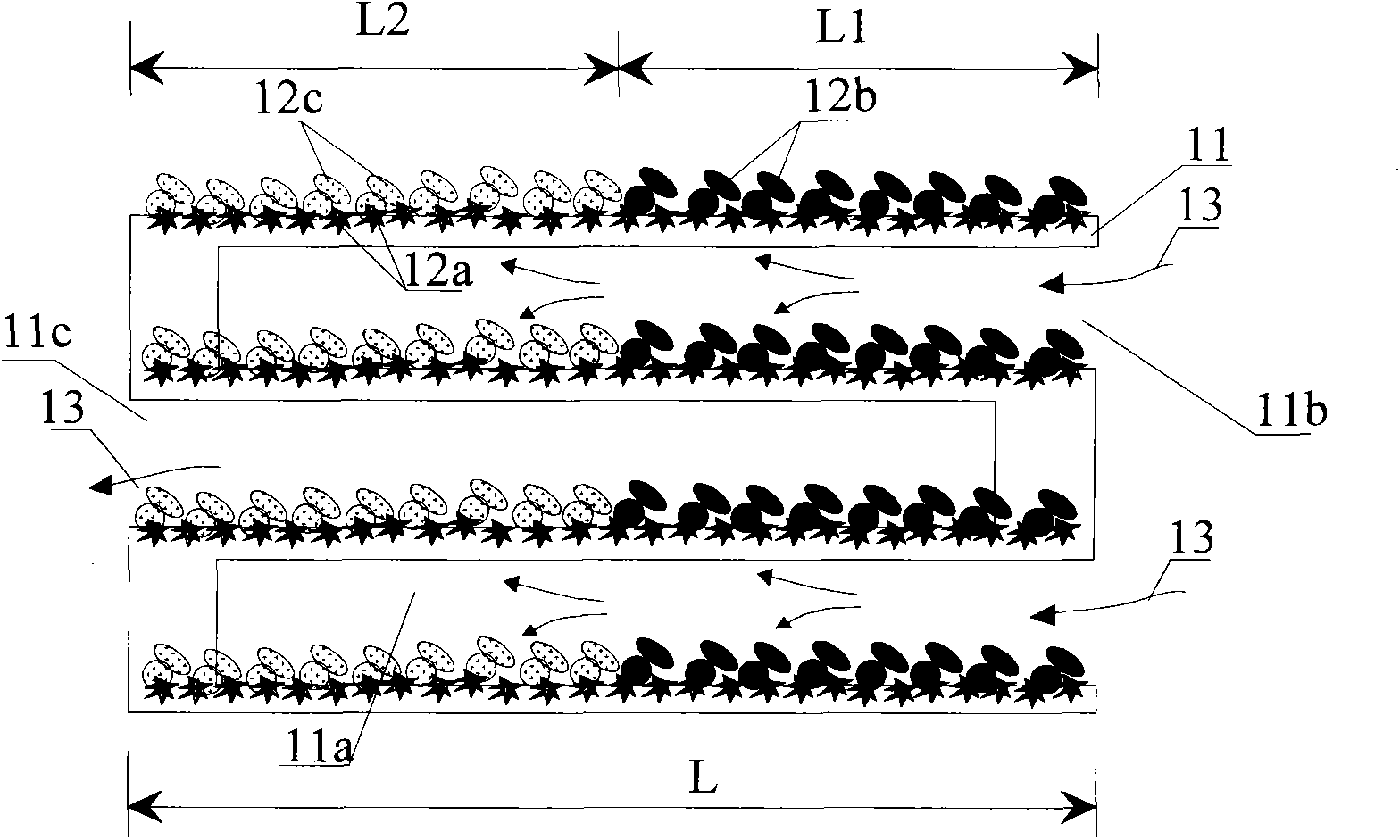

Image

Examples

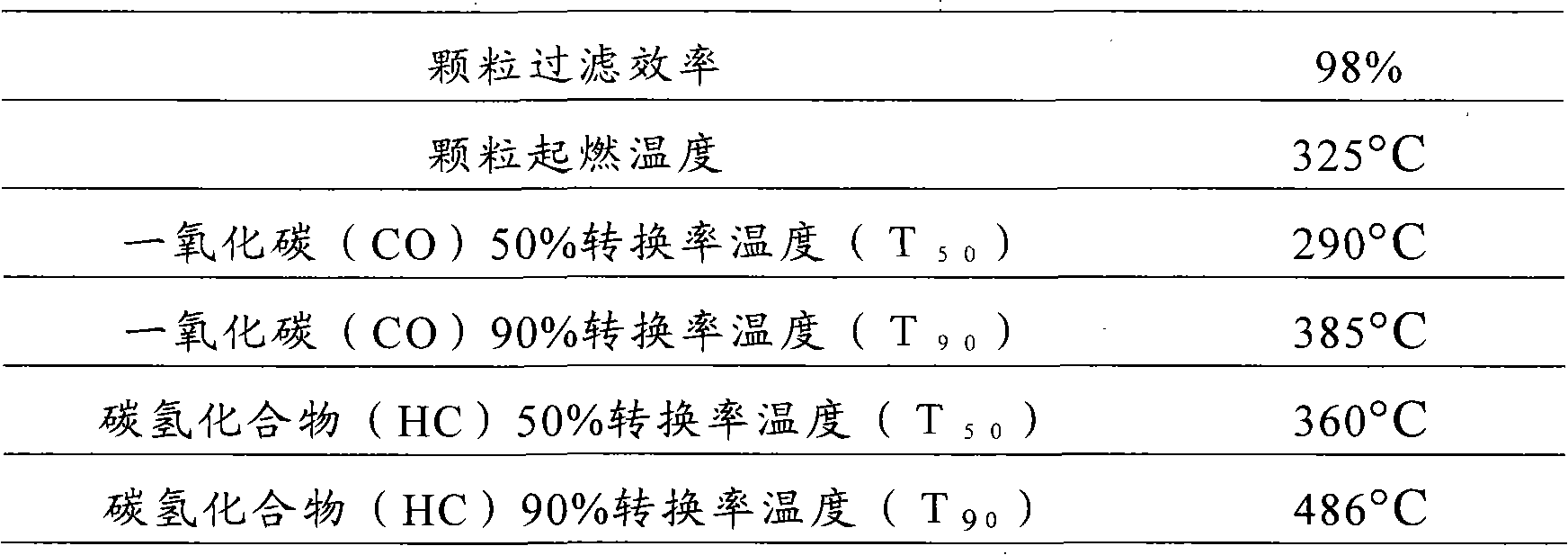

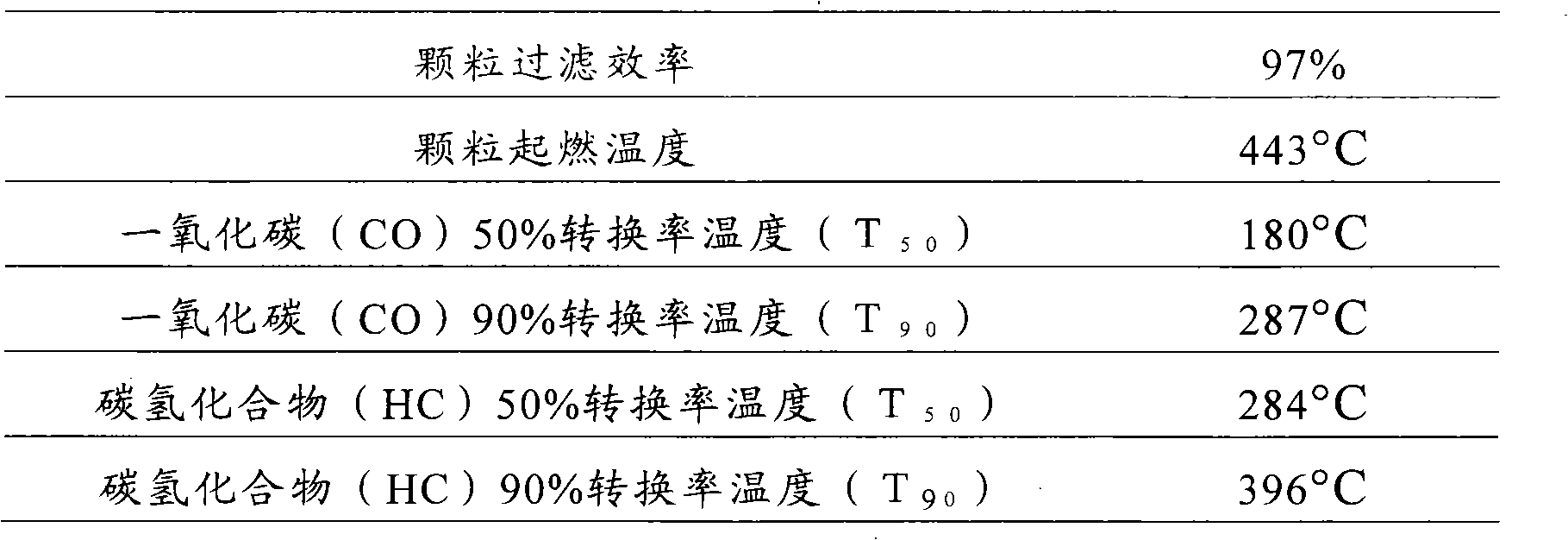

Embodiment 1

[0054] Take 28g (gram) tungsten silicate (SiO 2 -12WO 3 ) and 55g amine molybdate (NH 4 ) 6 Mo 7 o 24 Dissolve in 1500 ml of deionized water to obtain a slurry, and then heat the slurry to 40°C to 60°C in a water bath, and keep stirring the slurry during heating to completely dissolve the tungsten silicate and amine molybdate to obtain a solution.

[0055] Take the wall-flow honeycomb cordierite catalyst carrier and dry it at 120°C for 2 hours at a constant temperature. The diameter of the catalyst carrier is 5cm, the length is 6cm, and the porosity of the catalyst carrier is selected as 60%. solution, and the catalyst support was immersed in the solution for 10 minutes. The impregnated catalyst carrier was dried at 120° C. under an air atmosphere for 7 hours, and then the dried catalyst carrier was calcined in an electric heating furnace at 650° C. for 5 hours under an air atmosphere to obtain the first layer of catalyst on the catalyst carrier.

Embodiment 2

[0057] Get 100g potassium nitrate (KNO3) and 92g cobalt nitrate (Co(NO 3 ) 2 ) was dissolved in 1500 ml of deionized water to obtain a slurry, which was heated to 40°C to 60°C in a water bath, and the slurry was continuously stirred until potassium nitrate and cobalt nitrate were completely dissolved to obtain a solution. According to the water absorption of the wall-flow honeycomb ceramic carrier, measure 1 / 2 of the water absorption from the above solution, and immerse the outlet end of the catalyst carrier with the first layer of catalytic layer in Example 1 into the solution , the impregnation time was 5 minutes, the impregnated carrier was dried in air at 120°C for 6 hours, and then placed in an electric heating furnace for sintering and calcining in air at 650°C for 6 hours to obtain the second layer of catalyst at the outlet section of the catalyst carrier.

Embodiment 3

[0059] With 66g praseodymium nitrate (Pr(NO3) 3 ), 136g zirconium nitrate Zr (NO 3 ) 4 , 10 milliliters of 11wt% palladium nitrate (Pd(NO3) 2 ) solution was added into 1500 ml of deionized water to obtain a slurry, the slurry was heated to 40° C. to 60° C., and the slurry was continuously stirred until a completely dissolved solution was obtained. According to the water absorption of the wall-flow honeycomb ceramic carrier, measure 1 / 2 of the water absorption from the solution, and immerse the inlet end of the carrier with the first catalytic layer prepared in Example 1 in the solution. The impregnated catalyst carrier was dried in air at 120° C. for 6 hours for 5 minutes, and calcined in an air atmosphere of 600° C. for 6 hours to obtain the second layer of catalyst on the inlet section of the catalyst carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com