Porous yttrium-cerium-zirconium solid solution and preparation method thereof

A technology of cerium-zirconium solid solution and aqueous solution, which is applied in the field of porous yttrium-cerium-zirconium solid solution and its preparation, can solve the problems of small specific surface area and sintering, and achieve the effect of large specific surface area, high degree of crystallization, and easy industrial operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

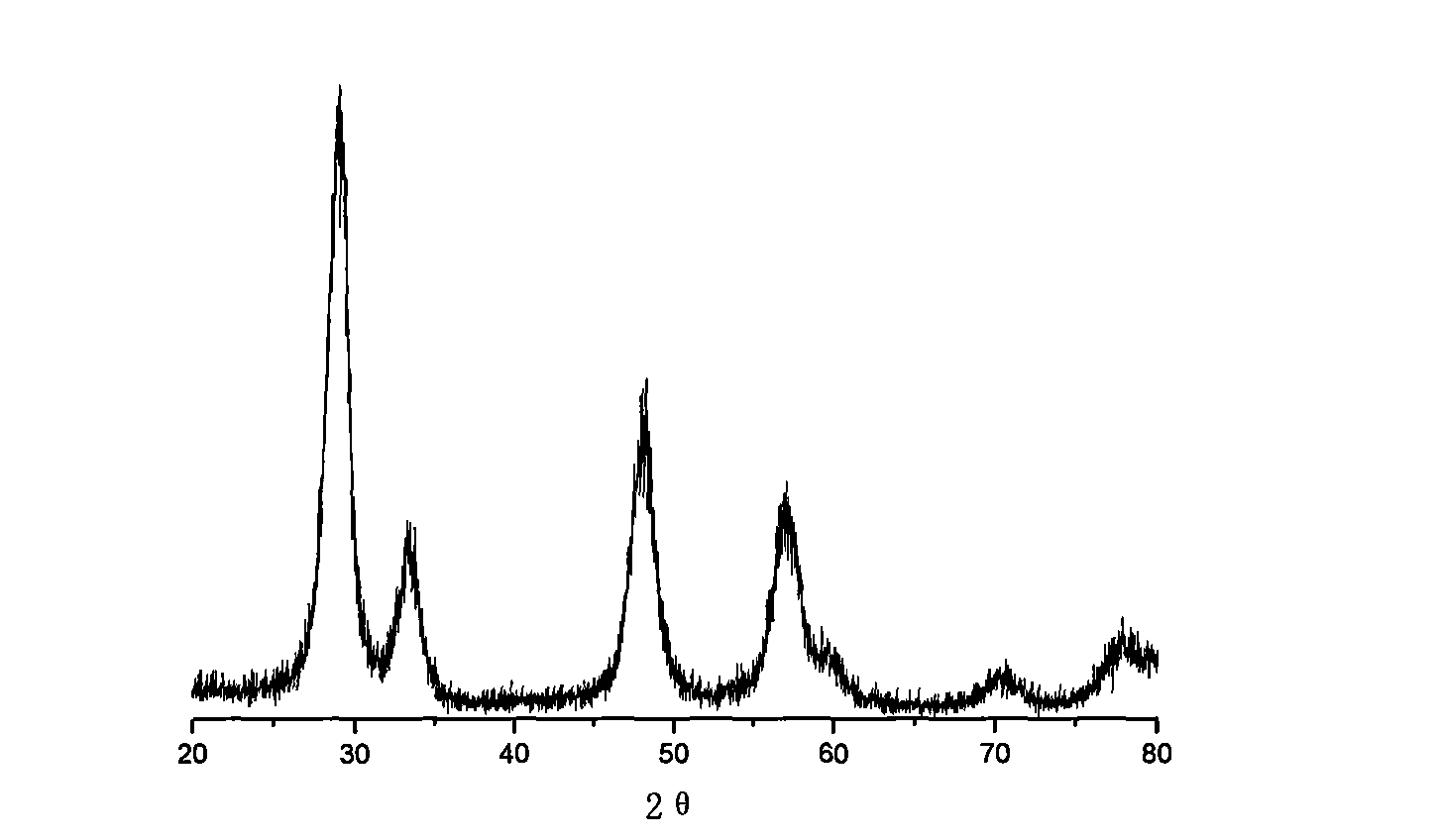

Image

Examples

Embodiment 1

[0042] Add 0.4g ammonium persulfate and 0.8g NaHCO to the four-neck flask 3 and 120mL of distilled water, stirred for 10min, added 20mL of styrene monomer, and passed nitrogen into the four-necked flask for protection, raised the temperature to 70°C and reacted for 1h, then added 4g of γ-(methacryloyloxy)propyltrimethoxy base silane, continue to react for 9h, after the reaction is completed, cool and stand still to obtain a white emulsion, which is ready for use.

[0043] Take the above white emulsion, add water to make active polystyrene microspheres 0.2g mL-1 200mL of active polystyrene emulsion was poured into a three-necked flask equipped with a condenser and a stirrer at a stirring speed of 100rpm, and 1000mL of deionized water and 18g of polyethylene glycol 4000 were added.

[0044] 90mL concentration is 0.5mol L -1 cerous chloride aqueous solution, 45mL concentration is 1mol L -1 zirconium oxychloride aqueous solution and 100mL concentration is 0.1mol L -1 Add the yt...

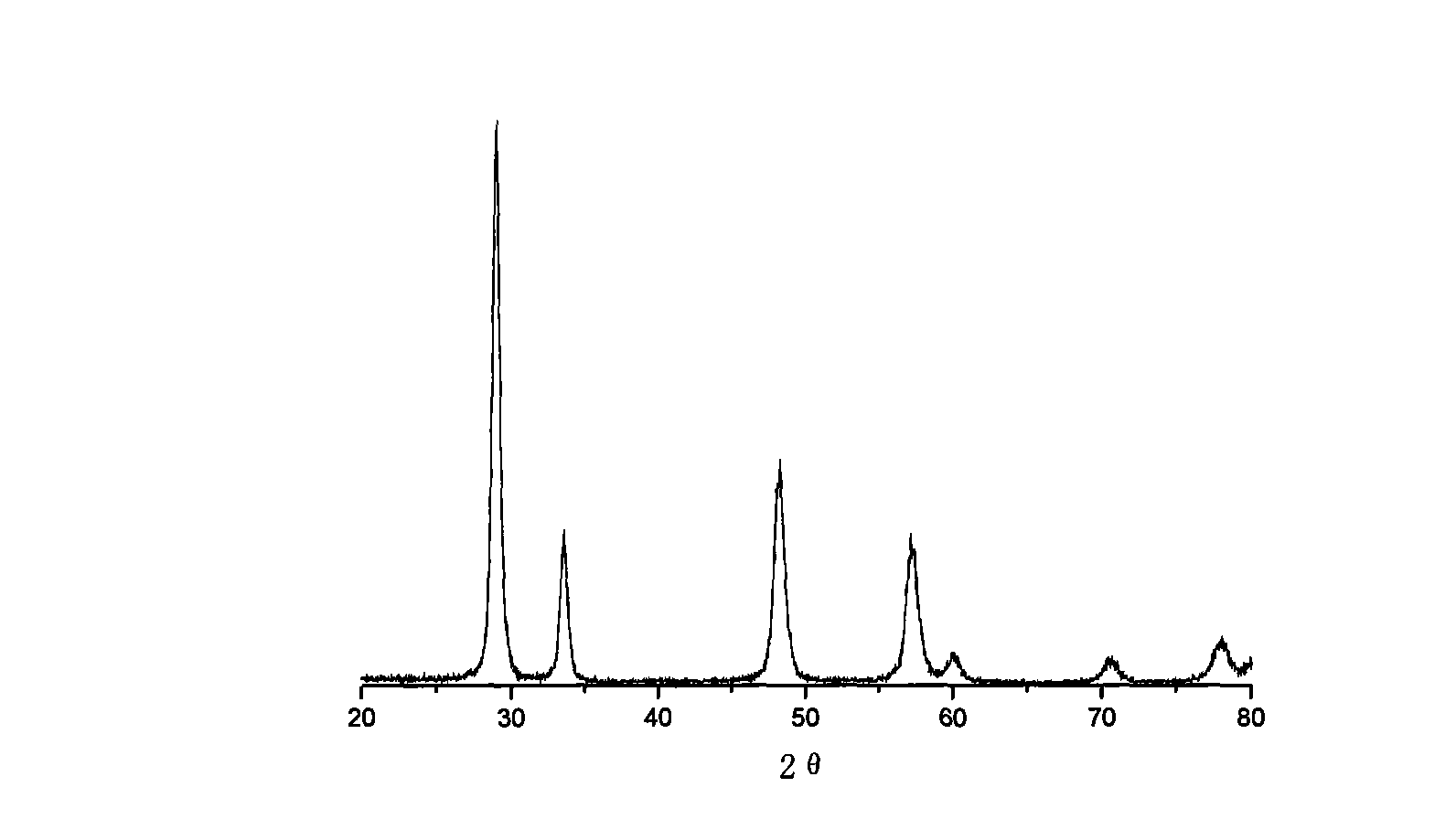

Embodiment 2

[0046] Add 0.4g ammonium persulfate, 0.1g sodium dodecylbenzenesulfonate and 120mL distilled water into the four-necked flask, stir for 10min, add 20mL styrene monomer, and pass nitrogen into the four-necked flask for protection, and heat up to After reacting at 70°C for 1 hour, add 4 g of γ-(methacryloyloxy)propyltrimethoxysilane and continue the reaction for 9 hours. After the reaction is completed, cool and stand still to obtain a white emulsion for use.

[0047] Take the above-mentioned white emulsion, adjust and make active polystyrene microspheres 0.23g mL -1 200mL of active polystyrene emulsion was poured into a three-necked flask equipped with a condenser and a stirrer at a stirring speed of 100rpm, and 1000mL of deionized water and 20g of polyethylene glycol 2000 were added.

[0048] 120mL concentration is 0.5mol L -1 cerous nitrate aqueous solution, 60mL concentration is 0.5mol L -1 zirconyl nitrate aqueous solution and 50mL concentration is 0.2mol L -1 Add the yt...

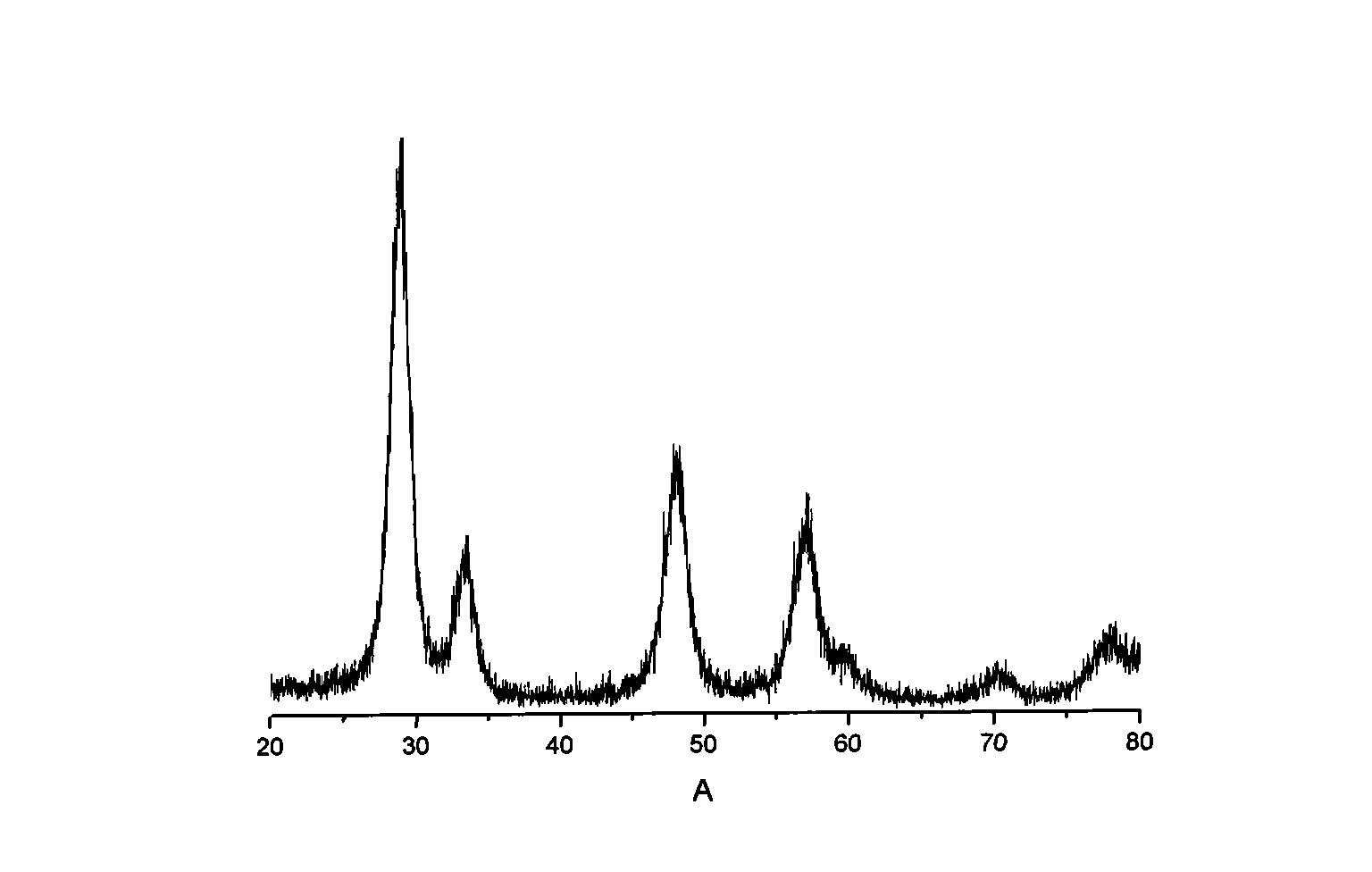

Embodiment 3

[0050] Add 0.4g ammonium persulfate and 0.8g KHCO to the four-necked flask 3 and 120mL of distilled water, stirred for 10min, then added 20mL of styrene monomer, and passed nitrogen into the four-necked flask for protection, raised the temperature to 70°C and reacted for 1h, then slowly added 4g of γ-(methacryloyloxy)propyl Trimethoxysilane was continued to react for 9 hours, and after the reaction was completed, it was cooled and left still to obtain a white emulsion for use.

[0051] Take the above white emulsion, add water to make active polystyrene microspheres 0.25g mL -1 200mL of active polystyrene emulsion was poured into a three-necked flask equipped with a condenser tube and a stirrer at a stirring speed of 100rpm, and 1000mL of deionized water and 20g of polyethylene glycol 4000 were added.

[0052] The 50mL concentration is 1mol·L -1 cerous nitrate aqueous solution, 40mL concentration is 1mol L -1 zirconyl nitrate aqueous solution and 25mL concentration is 0.4mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com