Water-based polyurethane

A technology of water-based polyurethane and water-based curing agent, applied in the direction of polyurea/polyurethane coating, polyurea/polyurethane adhesive, adhesive type, etc., can solve the problem of polyurethane insoluble in water and environmental protection, and achieve excellent chemical resistance properties, low viscosity, and good film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

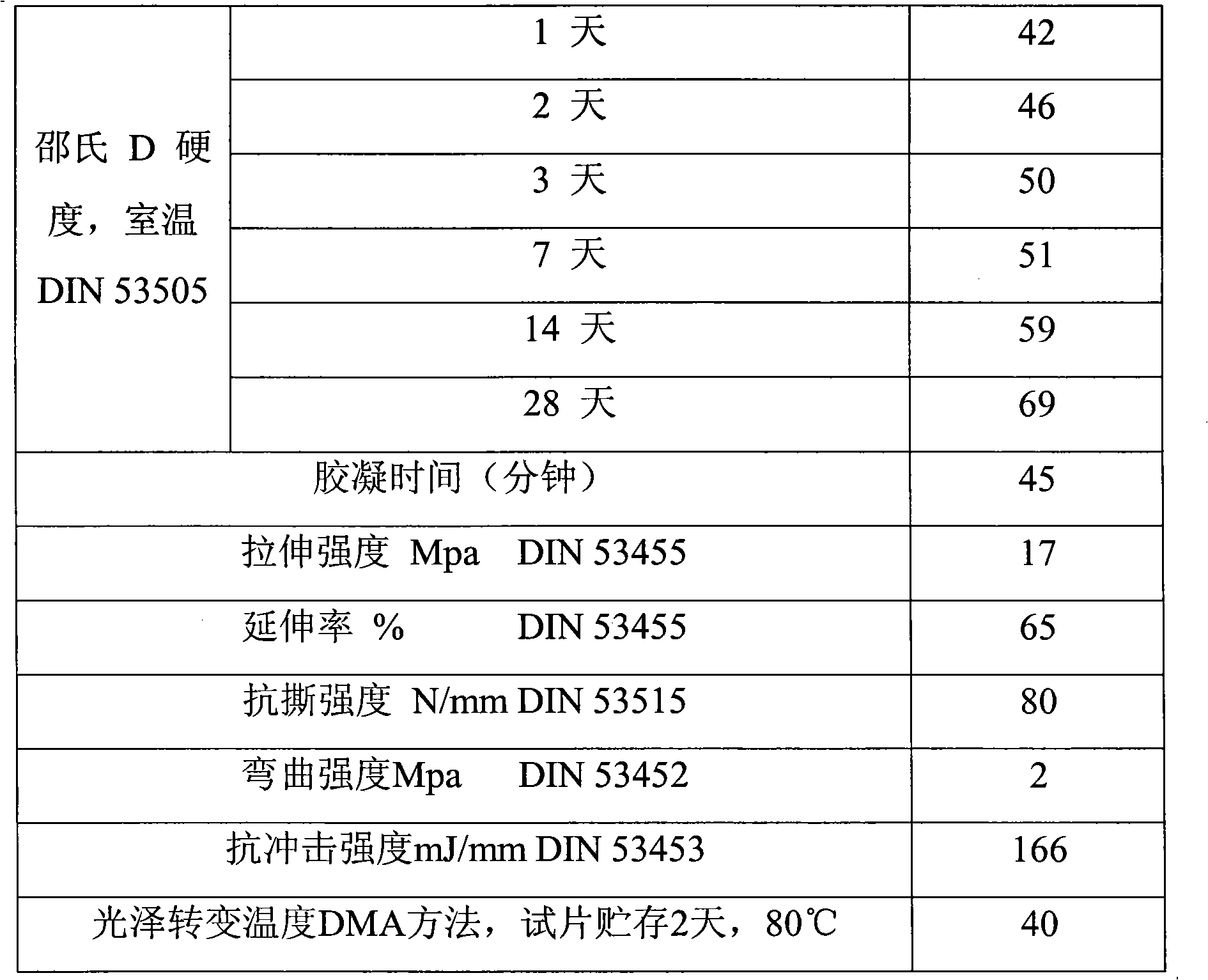

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiment:

[0017] (1) Preparation of Polyol Resin Emulsion:

[0018] 40-80 parts by weight of SOVERMOL polyol resin, non-ionic emulsifier accounting for 2-10% by weight of polyol resin, and 30-52 parts by weight of water are weighed.

[0019] Its preparation method comprises the following steps:

[0020] A. Put SOVERMOL polyol resin into a 500ml beaker, heat to 20-80°C, add nonionic emulsifier A-3065;

[0021] B. Put the dispersing head of the emulsifying machine in a beaker, turn on the emulsifying machine, preheat the dispersing head, and disperse the mixed solution of polyol resin and emulsifier obtained in step A evenly;

[0022] C. Add water at 30-80°C to the mixed solution obtained in step B, stop adding water when the mixed solution reaches the phase inversion critical point, stir for 3-10 minutes until the mixed solution is uniform, add the remaining water, and continue stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com