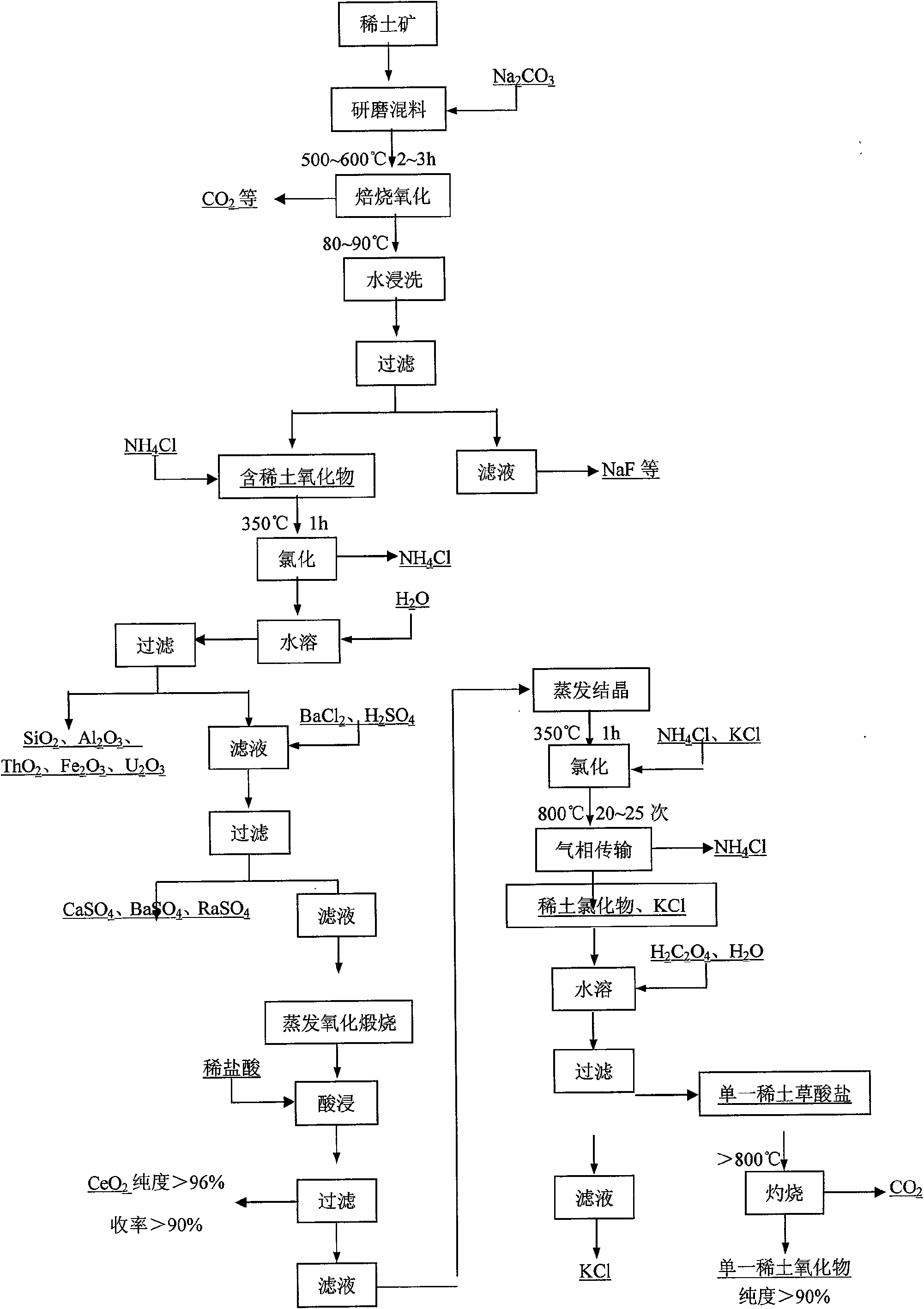

Method for separating rare earth oxides from rare earth ore by using ammonium chloride-potassium chloride gas phase transmission

A technology of rare earth oxide and gas phase transmission, applied in the direction of improving process efficiency, etc., can solve problems such as long reaction time, human poisoning, even sudden death, explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment:

[0016] Bastnaesite raw ore, main chemical composition (%): REO (16.8), Al 2 o 3 (10.7), Fe 2 o 3 (3.7), CaO(6.4), BaO(11.2), MgO(1.7), MnO 2 (0.6), PbO(0.6), SiO 2 (41.6), F (2.8), ThO 2 (0.2), P(0.4). CeO in rare earth ores 2 The content accounts for 46.5%, and the non-cerium rare earth oxides lanthanum oxide, praseodymium oxide and neodymium oxide account for 51%.

[0017] Grind the above-mentioned bastnaesite raw ore to less than 50 μm, take 70 g, add 30 g of sodium carbonate, mix evenly, put it into a high-alumina ceramic reactor, heat up to 300 ° C, keep it warm for 1 hour, and continue to heat up to 500 ° C within 1 hour ~600°C, keep warm for 2-3 hours; mix the decomposed solid product with water at a solid-to-liquid ratio of 1:5, temperature 80-90°C, stir for 1-2 hours, settle, filter, and rinse to obtain mixed rare earth oxide The solid matter of the compound is grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com