Process for producing ferrous fumarate

A ferrous fumarate and production process technology, which is applied in carboxylate preparation, animal feed, animal husbandry, etc., can solve the problems of high price, lack of qualitative and quantitative analysis and testing methods, difficult application, etc., and achieve iron content High, good chemical stability, high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

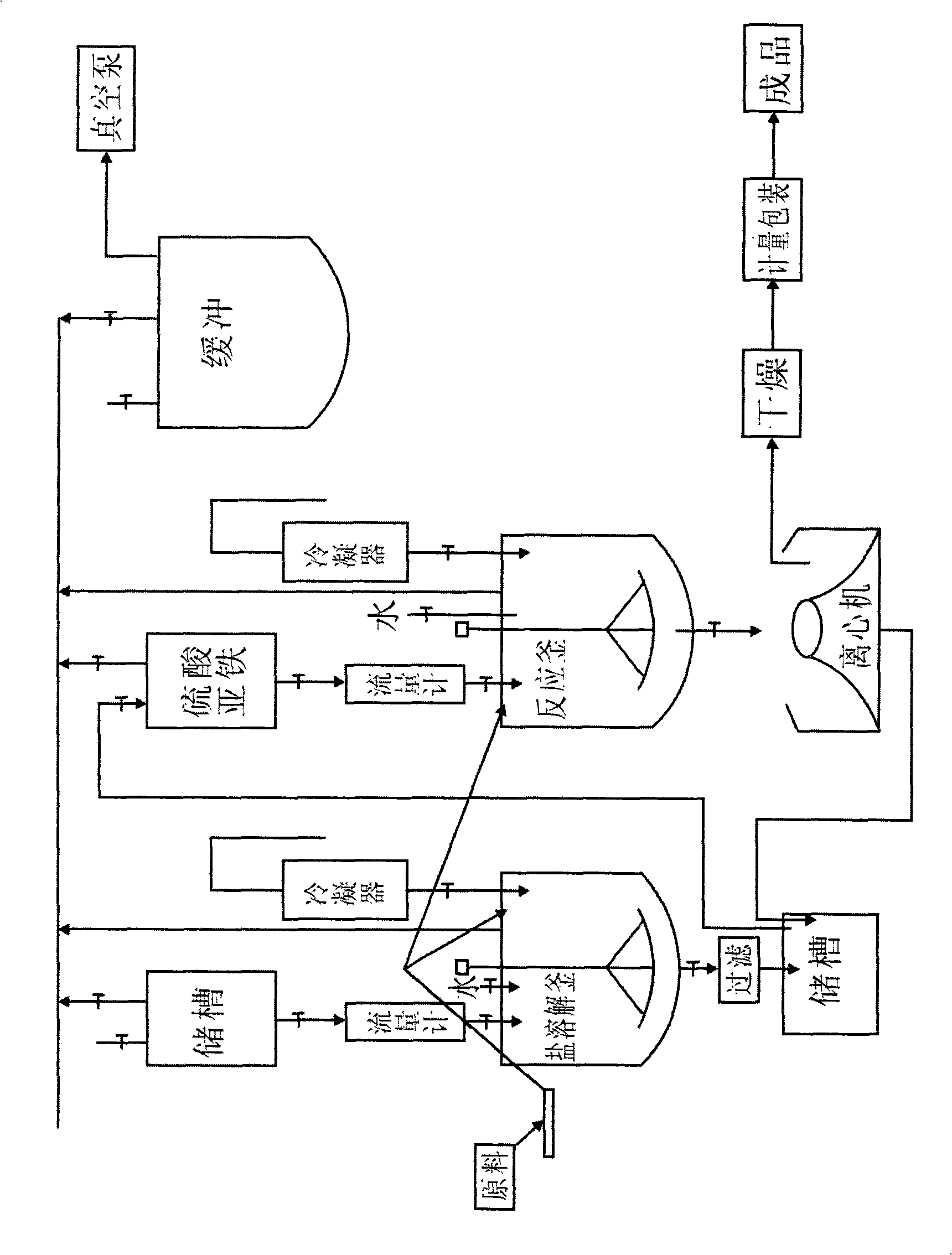

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0016] As shown in the drawings, the production process of the present invention is as follows: add water into the salt dissolution tank and raise the temperature to 80-85°C—add fumaric acid and soda ash in sequence—raise the temperature to 100°C—together with ferrous sulfate Add to the reaction kettle—heat up to 100°C—chemical reaction—discharging, cooling—centrifugal separation—drying—measurement packaging—finished product. Soda ash is sodium hydroxide, used to react with fumaric acid to obtain sodium fumarate, sodium fumarate reacts with ferrous sulfate to obtain ferrous fumarate, ferrous fumarate is organic iron, and the ferrous iron in it It is easily absorbed by animals and will not cause harm to animals' bodies.

[0017] As shown in the figure, in the centrifugal separation process in the centrifuge, the separated mother liquor is introduced into the storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com