Nanometer microsphere or hollow sphere of casein or casein-polyacrylic acid compound and preparation method and application thereof

A technology of polyacrylic acid and nano-microspheres, which is applied to the preparation of microspheres, microcapsule preparations, and medical preparations of non-active ingredients. Degradability, good biocompatibility, and the effect of not being immune to the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

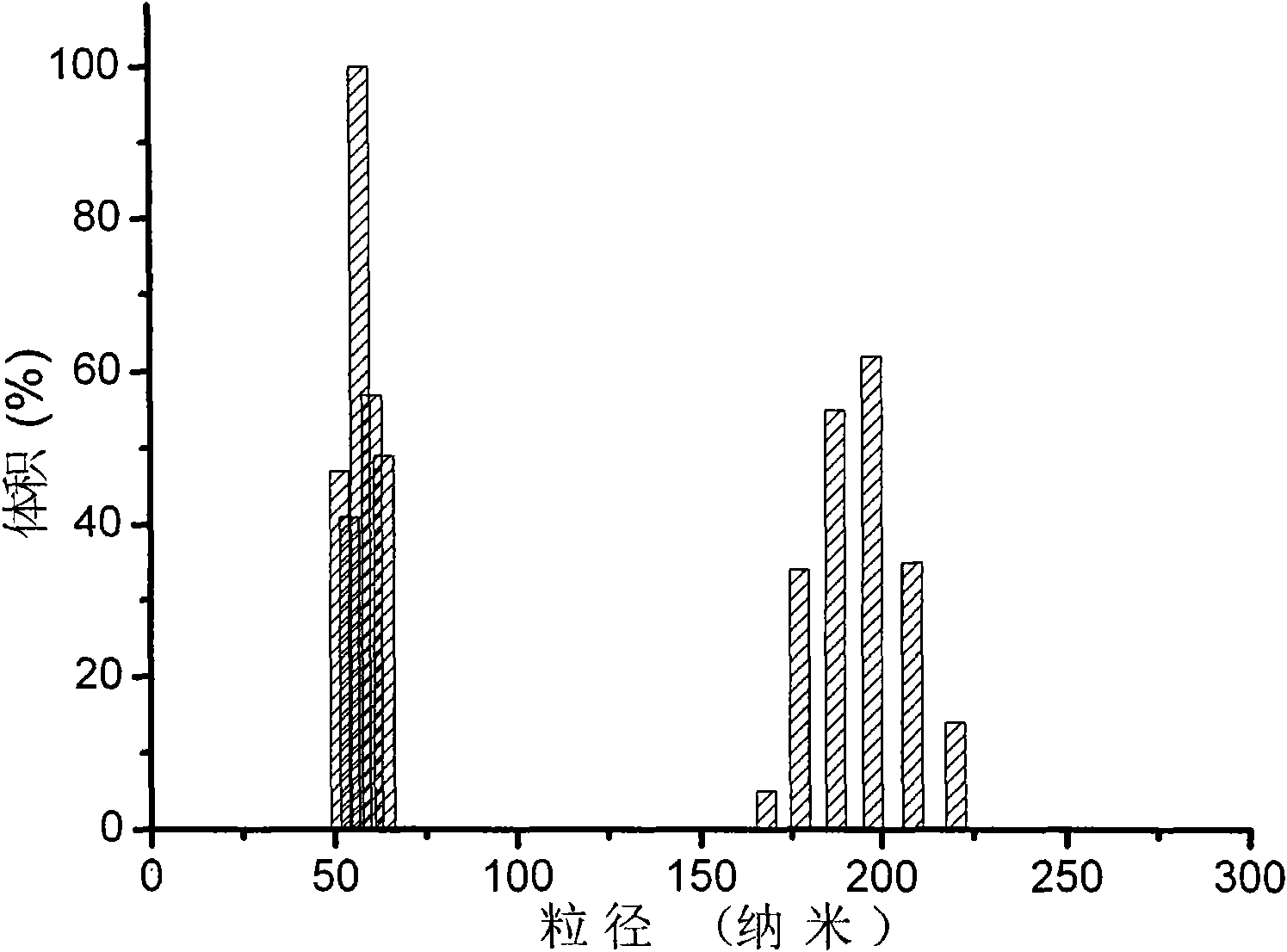

[0046] Add 40ml of distilled water, 0.08g of casein, and 0.4g of acrylic acid into a 100ml three-neck flask, and then heat it to 90°C. g. As the reaction progresses, the color of the system gradually changes from colorless to light blue to milky blue. At this time, remove the heat source, stop stirring, cool, filter, and use analytically pure hydrochloric acid and distilled water to adjust pH=3 for dialysis Media dialysis, adding 250ml of water each time, changing the water 20 times, dialysis to remove the small inorganic salt molecules and unreacted monomers in the system, and then the composite nano-microspheres can be obtained. 170nm, particle size distribution see Picture 1-1 , the transmission electron microscope photo see figure 2 . Take out the above liquid, add 40ul of 25% glutaraldehyde or 0.04g of calcium sulfate dihydrate to cross-link, react at 40°C for 24 hours and then filter, then use analytically pure hydrochloric acid and distilled water to prepare a dialy...

Embodiment 2

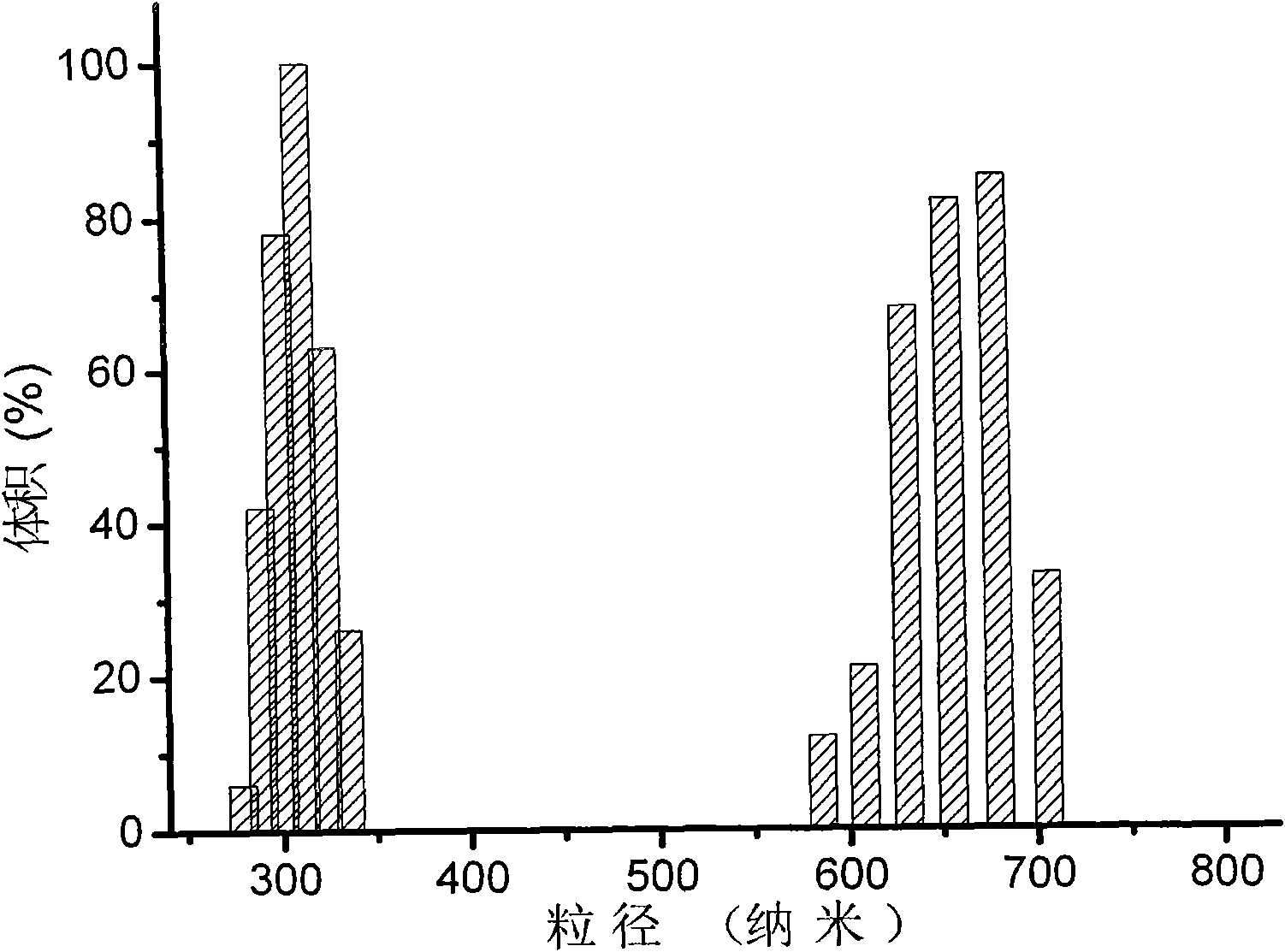

[0048] Add 40ml of distilled water, 0.08g of casein, and 0.6g of acrylic acid into a 100ml three-necked flask, and then heat it to 90°C. g, as the reaction progresses, the color of the system gradually changes from colorless to light blue to milky blue. At this time, remove the heat source, stop stirring, cool, filter, and dialyze to remove small inorganic salt molecules and unreacted The monomer can be used to obtain composite nano-microspheres, and the obtained nanoparticles are stored in a refrigerator at 4°C. Take out the above liquid, add 40 ul of 25% by mass glutaraldehyde or 0.04 g of calcium sulfate dihydrate for cross-linking, react at 40°C for 24 hours and then filter, if the nano-microspheres are dialyzed in water with pH=3, cross-linking can be obtained. The nano-microsphere 0.52 gram of the casein-polyacrylic acid composite of linking, average particle diameter is 210nm, and the content of polyacrylic acid is 85% in the composite microsphere; If this nano-microsph...

Embodiment 3

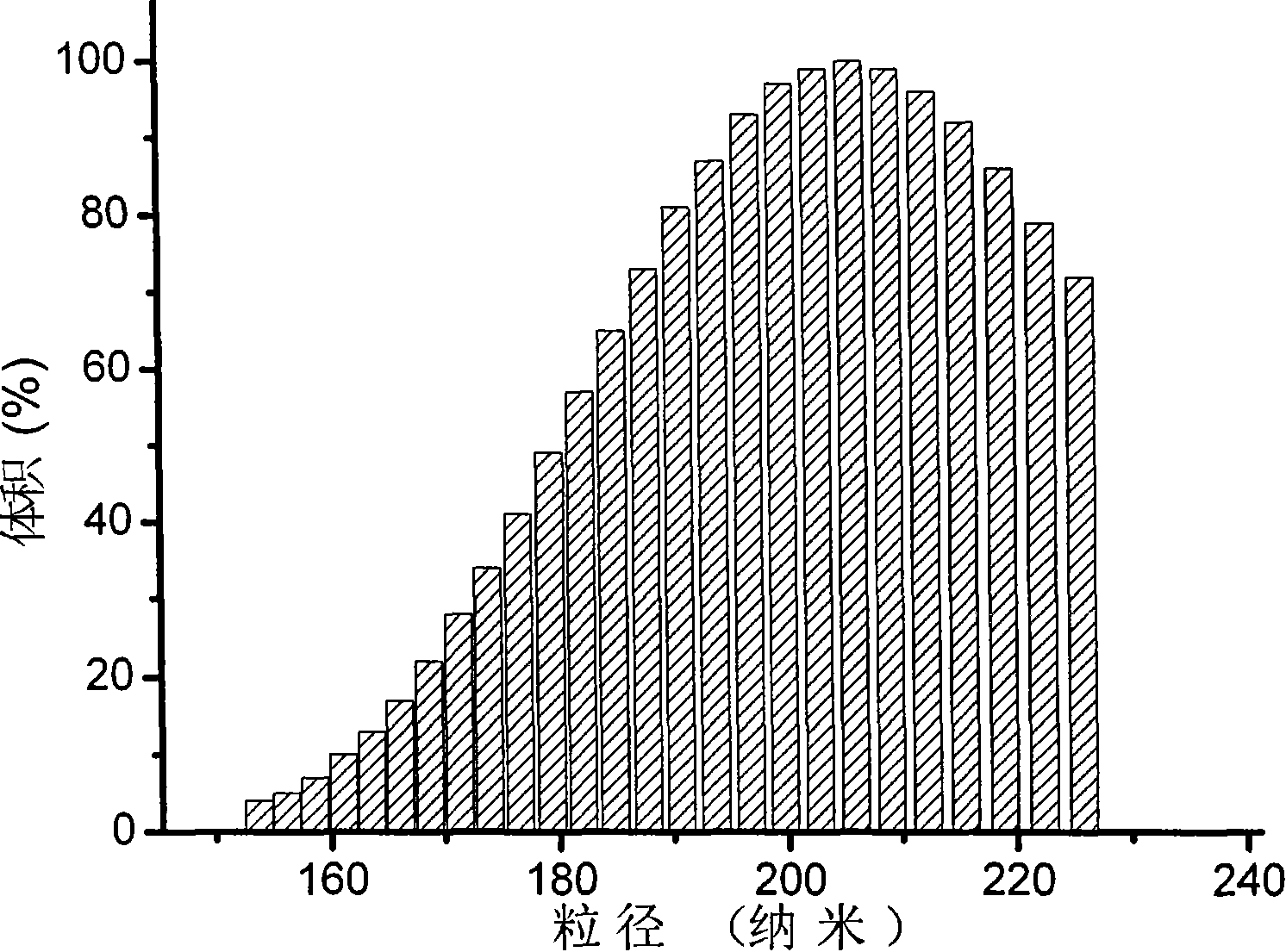

[0050] Add 40ml of distilled water, 0.12g of casein, and 0.6g of acrylic acid into a 100ml three-necked flask, and then heat it to 90°C. g, as the reaction progresses, the color of the system gradually changes from colorless to light blue to milky blue. At this time, remove the heat source, stop stirring, cool, filter, and dialyze to remove small inorganic salt molecules and unreacted The monomer can be used to obtain composite nano-microspheres, and the obtained nanoparticles are stored in a refrigerator at 4°C. Take out the above liquid, add 60ul of 25% by mass glutaraldehyde or 0.06g of calcium sulfate dihydrate to cross-link, react at 40°C for 24 hours and then filter, if the nano-microspheres are dialyzed in water with pH=3, cross-linking can be obtained. 0.6 grams of nano-microspheres of the casein-polyacrylic acid composite, the average particle diameter is 190nm, and the content of polyacrylic acid in the composite microspheres is 82%; if this nano-microsphere system i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com