Nano-porous palladium metal catalyst and preparing method thereof

A metal catalyst, nano-palladium technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problem of increasing precious metal loss, unfavorable synthesis and application, and reducing catalytic efficiency and other issues, to achieve the effect of improving catalytic activity, reducing loss, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation method of porous nano-palladium metal catalyst:

[0023] (1) An alloy containing an atomic number ratio of Cu:Pd of 75:25 (Cu 75 Pd 25 ) The sheet is mechanically polished with 3500-mesh sandpaper, then put into deionized water for ultrasonic 10min and taken out and dried with nitrogen for subsequent use;

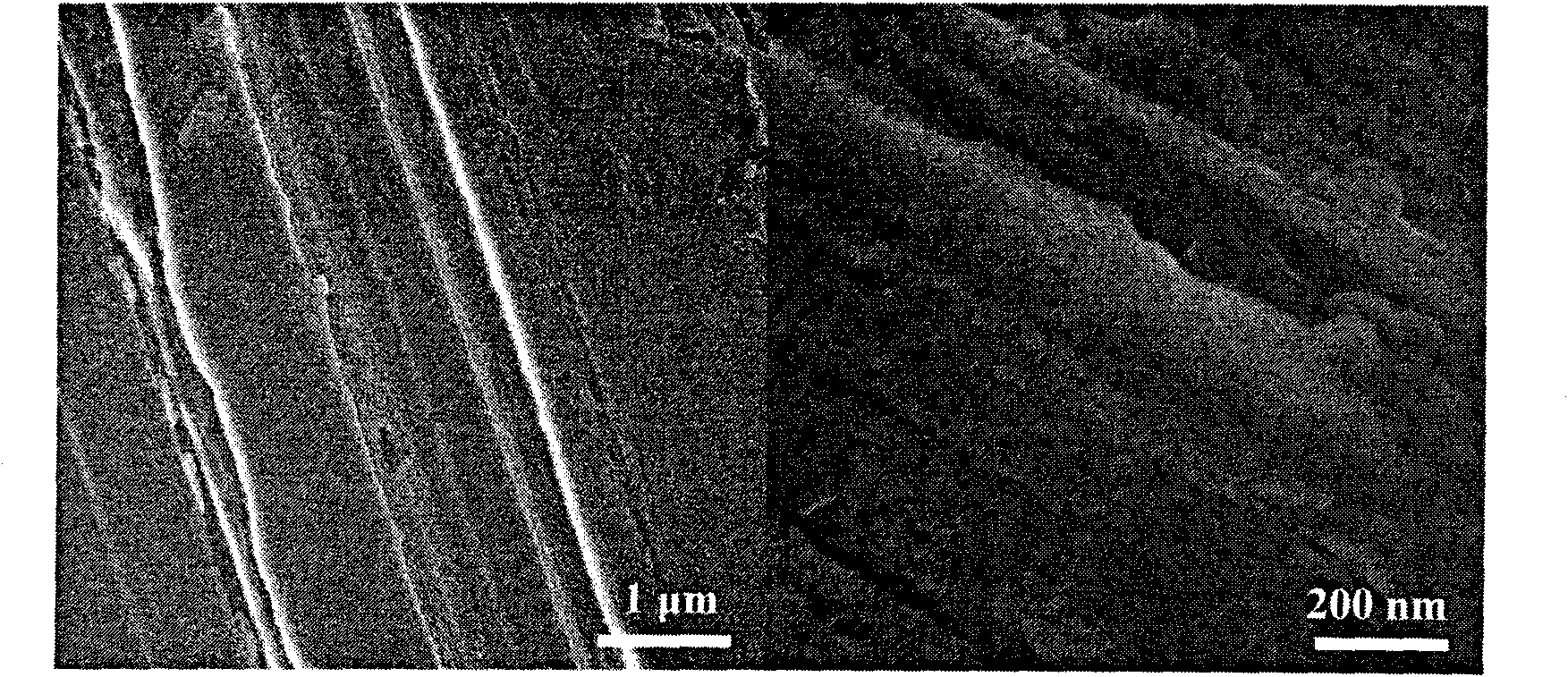

[0024] (2) Using the alloy sheet processed in step (1) as a working electrode in a three-electrode system, using a platinum sheet as a counter electrode and pure copper as a reference electrode, in the electrolytic cell of the three-electrode system, a room temperature ionic liquid ( 1-butyl-3-methylimidazolium tetrafluoroborate) was used as the electrolyte, and the potentiostatic method was used to selectively corrode and dissolve copper at a potential of 0.5V and 22 ° C. After 2 hours, the alloy flakes after dissolving copper were taken out, It was repeatedly rinsed with deionized water and dried with nitrogen to obtain Pd-rich porous nanostructured m...

Embodiment 2

[0027] Preparation method of porous nano-palladium metal catalyst:

[0028] (1) An alloy containing an atomic number ratio of Cu:Pd of 75:25 (Cu 75 Pd 25 ) The sheet is mechanically polished with 3500-mesh sandpaper, then put into deionized water for ultrasonic 10min and taken out and dried with nitrogen for subsequent use;

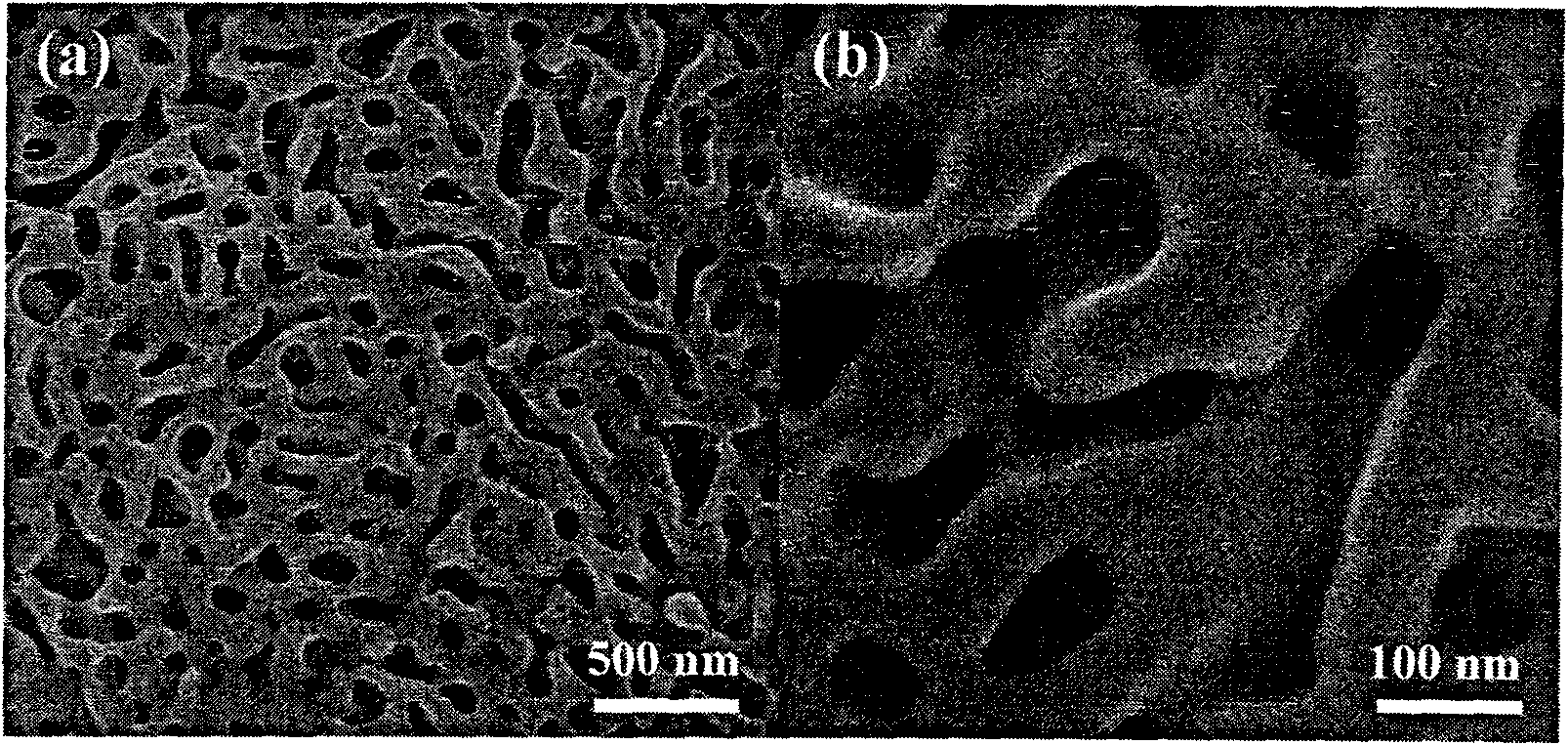

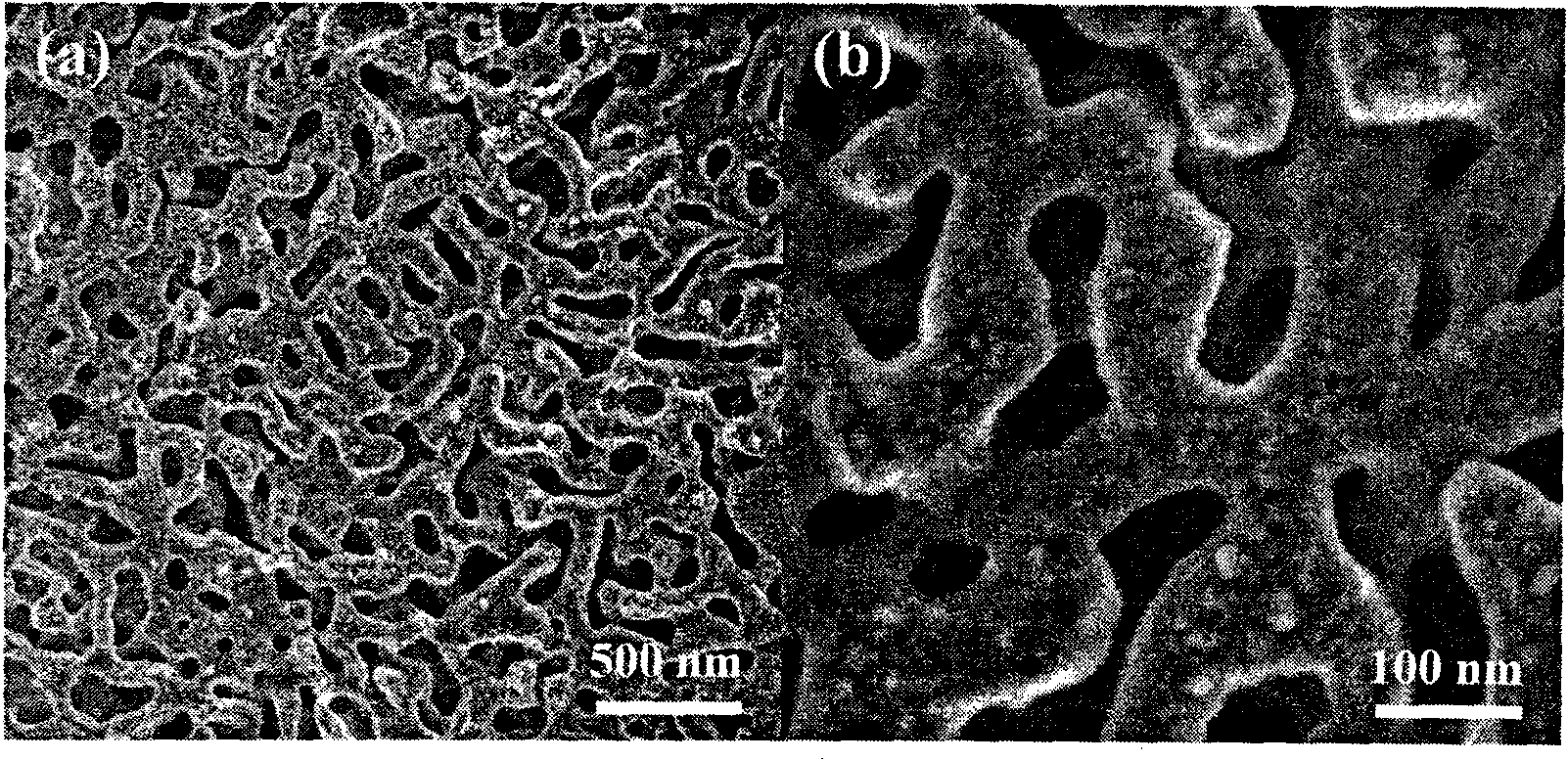

[0029] (2) Using the alloy sheet processed in step (1) as a working electrode in a three-electrode system, using a platinum sheet as a counter electrode and pure copper as a reference electrode, in the electrolytic cell of the three-electrode system, a room temperature ionic liquid ( 1-butyl-3-methylimidazolium tetrafluoroborate) was used as the electrolyte, and the potentiostatic method was used to selectively corrode and dissolve the copper at a potential of 1V and 10 °C. It was repeatedly rinsed with deionized water and dried with nitrogen to obtain Pd-rich porous nanostructured materials (such as figure 2 shown);

[0030] (3) immersing the Pd-ric...

Embodiment 3

[0032] The dechlorination efficiency of the porous nano-palladium metal catalyst prepared by the present invention is shown in Table 1 after the electrolysis of carbon tetrachloride and chlorobenzene at different potentials in an acidic medium. Nano-palladium is the working electrode, platinum sheet is the counter electrode, and the electrolyte solution is 5-50 mg L -1 Carbon tetrachloride and 0.5mol dm -3 H 2 SO 4 mixed solution or 5~50mgL -1 Chlorobenzene and 0.5mol dm -3 H 2 SO 4 The mixed solution was subjected to potentiostatic electrolysis at different potentials shown in Table 1. Experiments show that the porous nano-palladium metal catalyst has a good degradation effect on chlorine-containing organic compounds.

[0033] Table 1

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com