Bonding adhesive for leather, preparation method thereof and application of bonding adhesive in leather making process

An adhesive and leather technology, applied in the direction of adhesive types, ester copolymer adhesives, nitrile copolymer adhesives, etc., can solve the problems of poor adhesion, high oil slick, low mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

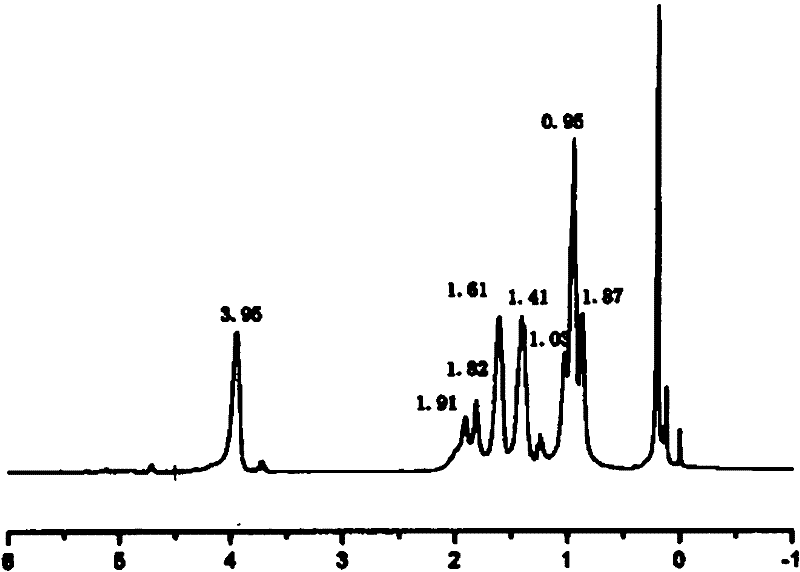

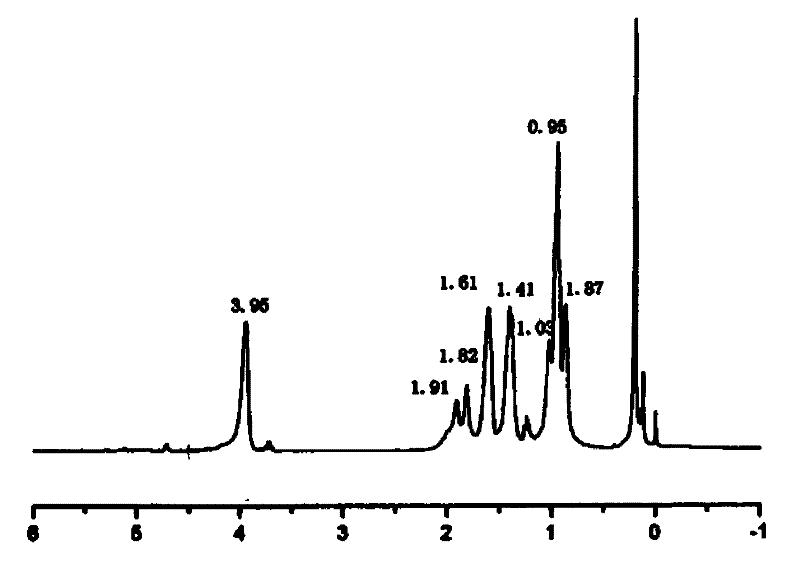

Image

Examples

Embodiment 1

[0048] The first step: the preparation of hydrogen-containing silicone oil n-butyl acrylate composite monomer,

[0049]In a four-necked flask equipped with electric stirring and reflux condenser, add a small amount of toluene, 12 parts of methyl hydrogen-containing silicone oil and a small amount of palladium carbon particles, pass nitrogen gas for 10 minutes, start heating and stirring, raise the temperature to 130°C, and start adding dropwise Add 300 parts of n-butyl acrylate dropwise in about 1 hour, and react at constant temperature for 10 hours. After the reaction stopped, the residual n-butyl ester was recovered by distillation under reduced pressure, cooled, and packaged for use.

[0050] The second step: polymerization of quaternary copolymerization hydrogen-containing silicone oil acrylate

[0051] Mix 22 parts of hydrogen-containing silicone oil n-butyl acrylate (NBMA-SiH), 18 parts of methyl methacrylate (MMA), 6 parts of methacrylic acid (MAA), 8 parts of N-methyl...

Embodiment 2

[0056] Example 1

[0057] The first step: the preparation of hydrogen-containing silicone oil n-butyl methacrylate composite monomer,

[0058] In a four-neck flask equipped with electric stirring and reflux condenser, add a small amount of ethanol, 15 parts of methyl hydrogen-containing silicone oil and a small amount of palladium carbon particles, pass nitrogen gas for 10 minutes, start heating and stirring, raise the temperature to 130°C, and start adding dropwise Add 400 parts of n-butyl methacrylate dropwise in about 1 hour, and react at constant temperature for 10 hours. After the reaction stopped, the residual n-butyl ester was recovered by distillation under reduced pressure, cooled, and packaged for use.

[0059] The second step: polymerization of quaternary copolymerization hydrogen-containing silicone oil acrylate

[0060] 28 parts of hydrogen-containing silicone oil n-butyl methacrylate (NBMA-SiH), 28 parts of methyl methacrylate (MMA), 6 parts of methacrylic acid...

Embodiment 3

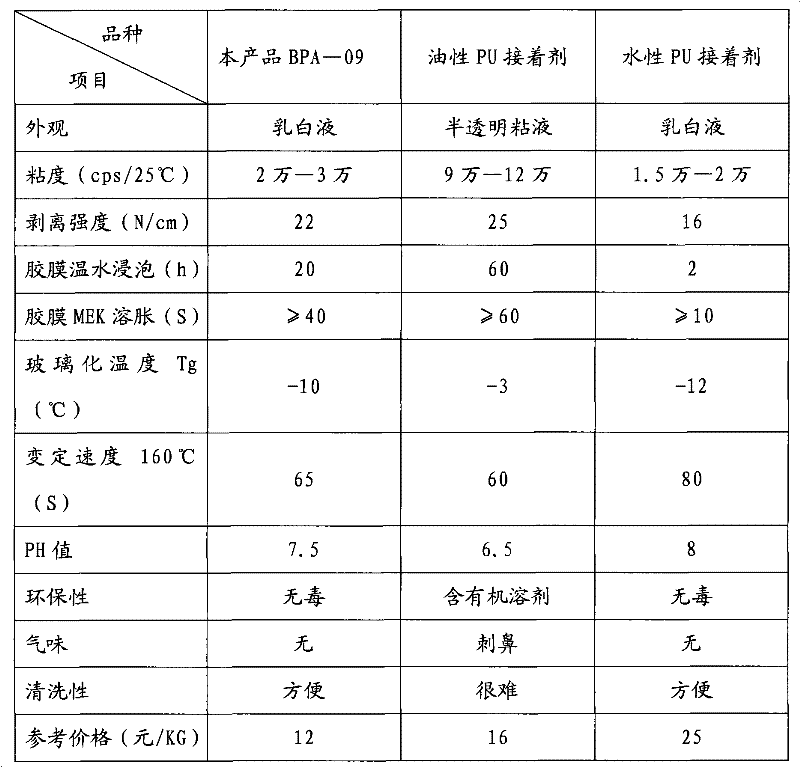

[0065] The application of adhesive for leather of the present invention in the tanning process, its formula is:

[0066] 1. 18 parts of tap water

[0067] 2. Wetting agent 0.22 parts

[0068] 3. 0.22 parts of defoamer

[0069] 4. Hydrogen-containing silicone oil acrylate emulsion 75 parts

[0070] 5. Filler (CaCO3) 22 parts

[0071] Put the above materials into the dispersing tank one by one, start the dispersing machine at 500-1000r / min, disperse at high speed for 1 hour, filter and pack to get the finished product, sizing at 100-130g / Y, used for laminating the backing cloth of PVC artificial leather.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com