Amorphous lanthanum-lutetium oxide resisting film and preparation method and application thereof

An oxide film and resistive film technology, applied in the field of microelectronic materials, can solve problems such as unsatisfactory speed and poor reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing an amorphous lanthanum-lutetium oxide resistive thin film, the preparation steps of which are as follows:

[0022] a) The lanthanum-lutetium oxide ceramic target 4 is made of La 2 o 3 and Lu 2 o 3 prepared by powder mixing solid phase sintering; 2 o 3 and Lu 2 o 3 After the powders are evenly mixed according to the molar ratio of 1:1, ball milling for 12 hours, pre-sintering at 1200°C, sintering at 1500°C for 15 hours after grinding, and making lanthanum-lutetium oxide ceramic target 4 after cooling;

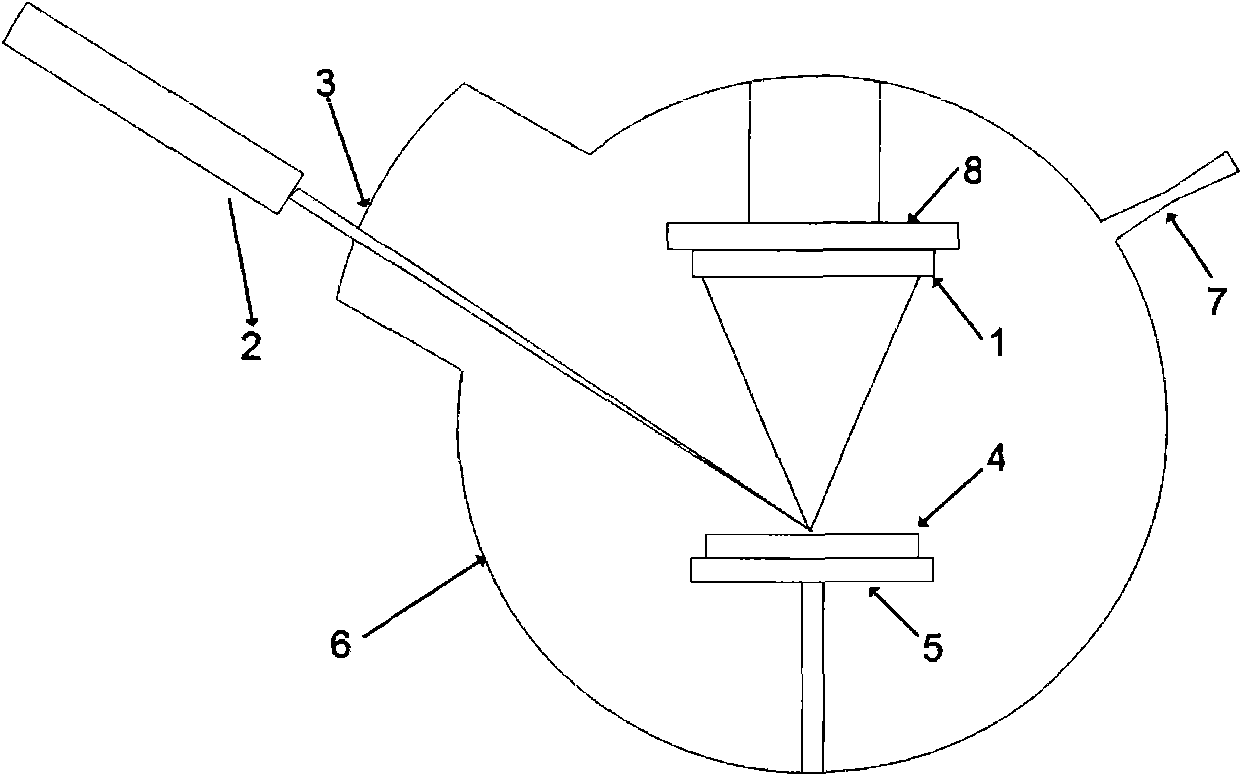

[0023] b) Fixing the lanthanum-lutetium oxide ceramic target 4 in a pulsed laser deposition film-making system (such as figure 1 shown), the substrate 1 is fixed on the substrate table 8, and they are all placed in the growth chamber 6 of the pulsed laser deposition film-making system;

[0024] c) Use a vacuum pump to evacuate the growth chamber 6 to about 2.0×10 through the interface valve 7 of the mechanical pump and the molecular pump. ...

Embodiment 2

[0029] A method for preparing a non-volatile resistive memory element using an amorphous lanthanum-lutetium oxide thin film, the specific preparation steps are as follows:

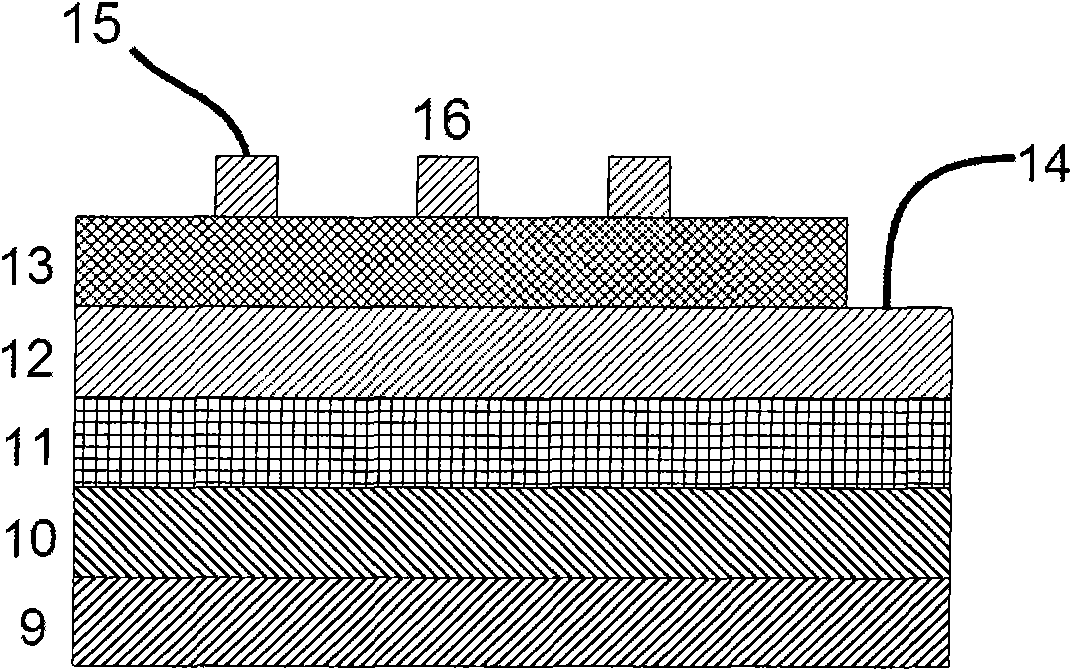

[0030] 1) A substrate with a Pt12 / Ti11 / SiO210 / Si(111)9 structure is placed in a pulsed laser deposition chamber, and an amorphous lanthanum-lutetium oxide thin film 13 is deposited using a pulsed laser deposition technique.

[0031] 2) Deposit the point electrode 16 on the above-mentioned boss by using the magnetron sputtering method of the metal mask, and its material is Pt, and the thickness is 100 nanometers;

[0032]3) Finally, connect the lead wires 14 and 15 from the electrode film 12 and the point electrode 16 respectively.

Embodiment 3

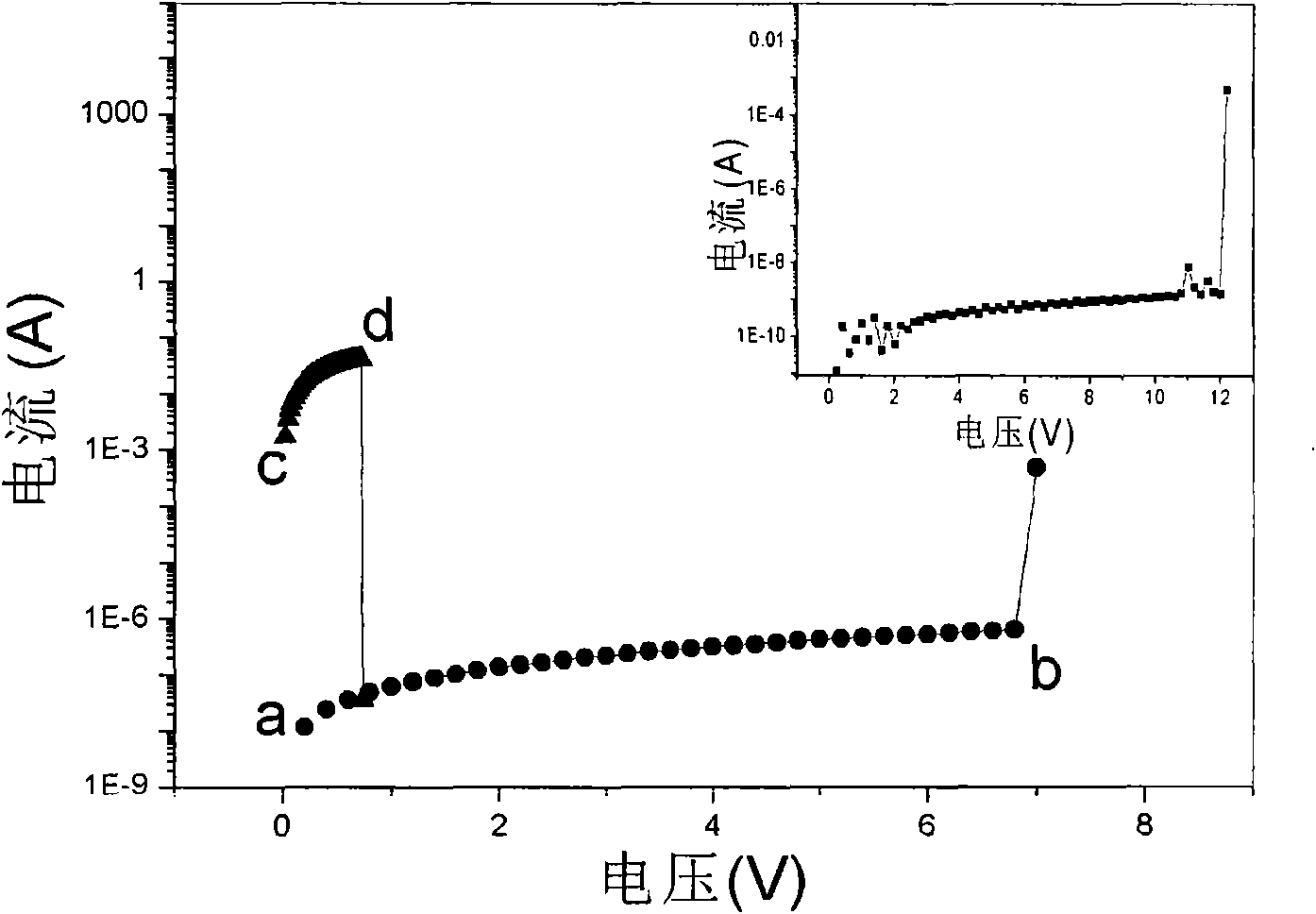

[0034] A method for preparing an amorphous lanthanum-lutetium oxide resistive thin film material, the preparation steps are: preparing a lanthanum-lutetium oxide ceramic target (4): adding La 2 o 3 and 60% Lu 2 o 3 After the powders are evenly mixed, ball mill for 12 hours, then pre-sinter at 1200°C, grind again and sinter at 1500°C for 12 hours to make the lanthanum lutetium oxide ceramic target 4; fix the lanthanum lutetium oxide ceramic target 4 in the pulse In the growth chamber 6 of the laser deposition film making system device, the growth chamber 6 is evacuated to 5.0×10 with a vacuum pump. -4 Below Pa; use an electric furnace wire to heat the substrate table 8 to 300°C. The substrate (1) is made of Pt / Ti / SiO 2 / Si(111); start the laser 2, make the laser beam focus on the lanthanum-lutetium oxide ceramic target material 4 through the focusing lens 3, and deposit a thick amorphous lanthanum-lutetium oxide film with a thickness of 30 nm on the substrate 1, at room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com