Catalyst used for preparing lower alcohol by synthesis gas, preparation method and application thereof

A catalyst and synthesis gas technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Independent transition metal oxides, difficult to increase the content of higher alcohols, etc., to achieve the effects of easy repetition and amplification, easy operation, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Catalyst preparation

[0030] Zirconyl nitrate (ZrO(NO 3 ) 2 2H 2 O) 18.31g and zinc nitrate (Zn(NO 3 ) 2 ·6H 2 (O) 34.11g is dissolved in the deionized water of 800mL, after being made into solution, under control temperature 70 ℃ and pH=10 conditions, with sodium carbonate solution (take by weighing 120g anhydrous Na 2 CO 3 Dissolve in 800mL deionized water) while feeding and fully stir with a mechanical stirrer to mix the precipitate evenly, and continue stirring and aging at 70°C for 2 hours after precipitation. Then use manganese nitrate and ferric nitrate (weigh 23.19g (Mn(NO 3 ) 2 50% aqueous solution and 27.14g (Fe(NO 3 ) 2 9H 2 O dissolved in 800 mL of deionized water) was deposited at 60° C. in parallel with ammonia water (25% volume concentration), kept at a pH of 10, and aged with stirring for 1.5 hours. Filter and wash the resulting deposition-precipitate with deionized water, then dry at 90°C under vacuum for 30 hours, transfer to a muffle...

Embodiment 2

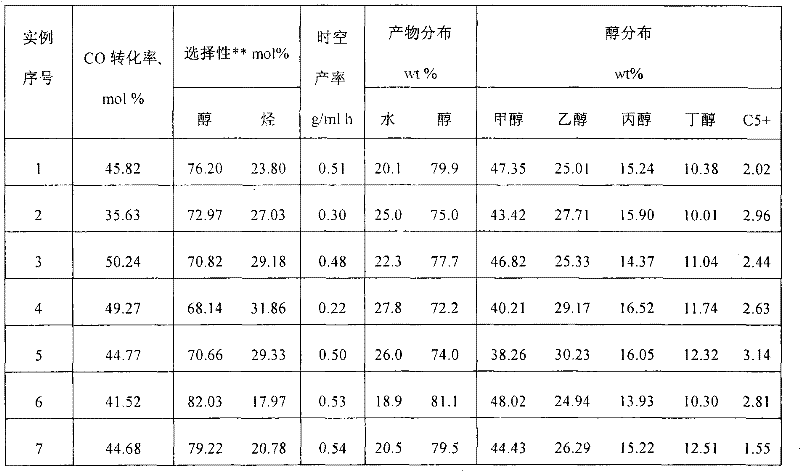

[0034] The preparation method and use conditions are the same as in Example 1, and the mass percentages of each metal in the PdCuFeMnZrZnO catalyst are Pd: 0.5%, Cu: 10.0%, Fe: 10.0%, Mn: 10.0%, Zr: 40.0%, Zn: 29.5%. The resulting low-carbon alcohol synthesis reaction results are shown in Table 1.

Embodiment 3

[0036] The preparation method and use conditions are the same as those in Example 1, and the mass percentage content of each metal in the PdCuFeMnZrZnO catalyst is Pd: 0.25%, Cu: 20.0%, Fe: 20.0%, Mn: 19.0%, Zr: 20%, Zn: 20%. The resulting low-carbon alcohol synthesis reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com