Single-component silicone seal gum for solar component and method for manufacturing same

A technology of silicone sealant and solar modules, applied in adhesives, electrical components, semiconductor devices, etc., can solve the problems of poor yellowing resistance, inconvenient construction, long surface drying time, etc., and achieve good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Embodiments of the present invention are as follows:

[0008] Material formula: 60 parts of hydroxyl-terminated polydimethylsiloxane, 60 parts of calcium carbonate reinforcing agent, 0.5% dibutyltin diacetate catalyst, 60 parts of methyl silane coupling agent, 2 parts of vinyl silane coupling agent.

[0009] Preparation process: Weigh 60kg of 40000mPa·S hydroxyl-terminated polydimethylsiloxane, 60kg of 1200 mesh calcium carbonate reinforcing agent, put them into a biaxial planetary stirring tank and stir for 30 minutes for vacuum dehydration, after cooling, add organic Tin catalyst, methyl silane coupling agent, vinyl silane coupling agent. Continue to stir under vacuum for 30 minutes to discharge the air bubbles in the mixed glue, and then press it into a plastic tube with a hydraulic filling machine.

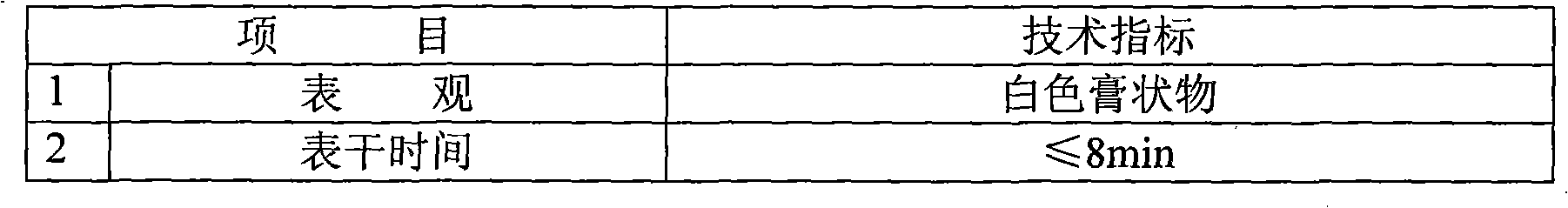

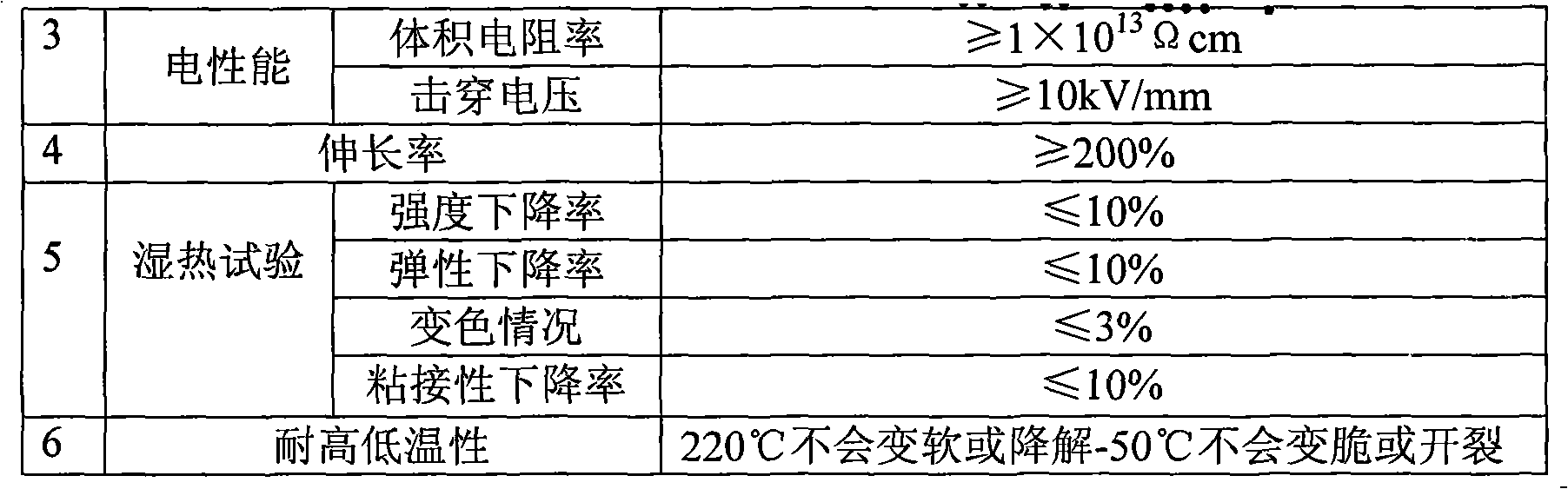

[0010] The RTV-1 glue produced by the above-mentioned process is used as a sealing material for solar energy building. After testing, the weather resistance performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com