Spinel structure lithium titanate and preparation method and application thereof

A technology of structural lithium titanate and spinel, applied in structural parts, chemical instruments and methods, titanium compounds, etc., can solve the problems of affecting battery performance, imperfect grain structure, uneven particle size and morphology, etc. Simple method, excellent electrochemical performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

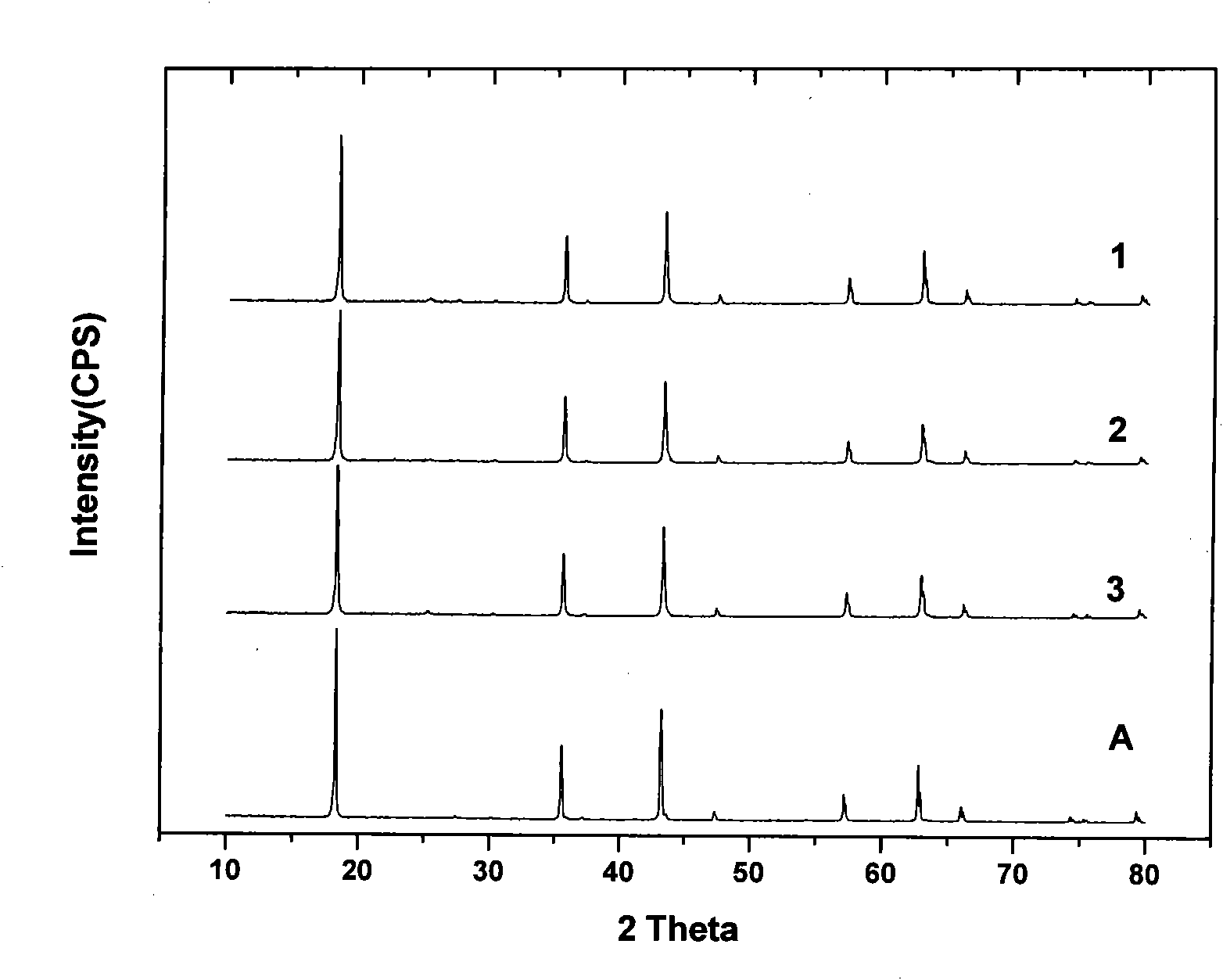

[0034] The present invention also provides a method for preparing the above-mentioned lithium titanate. The steps of the method include roasting the material containing the lithium source and the titanium source at a high temperature, and then keeping the material at a low temperature. The material containing lithium source and titanium source undergoes a sintering reaction under high temperature conditions, and the crystal lattice is perfected and the particle size is uniformly distributed under low temperature conditions to prepare lithium titanate with excellent electrochemical performance.

[0035] Among them, the temperature of high-temperature roasting is 700-1000°C, more preferably 800-900°C, the time of roasting is 5-20h, more preferably 8-12h; the present invention is to simplify the process and optimize the product, preferably only once The purpose of low temperature heat preservation is to achieve the perfect crystal lattice and uniform distribution of particle size ...

Embodiment 1

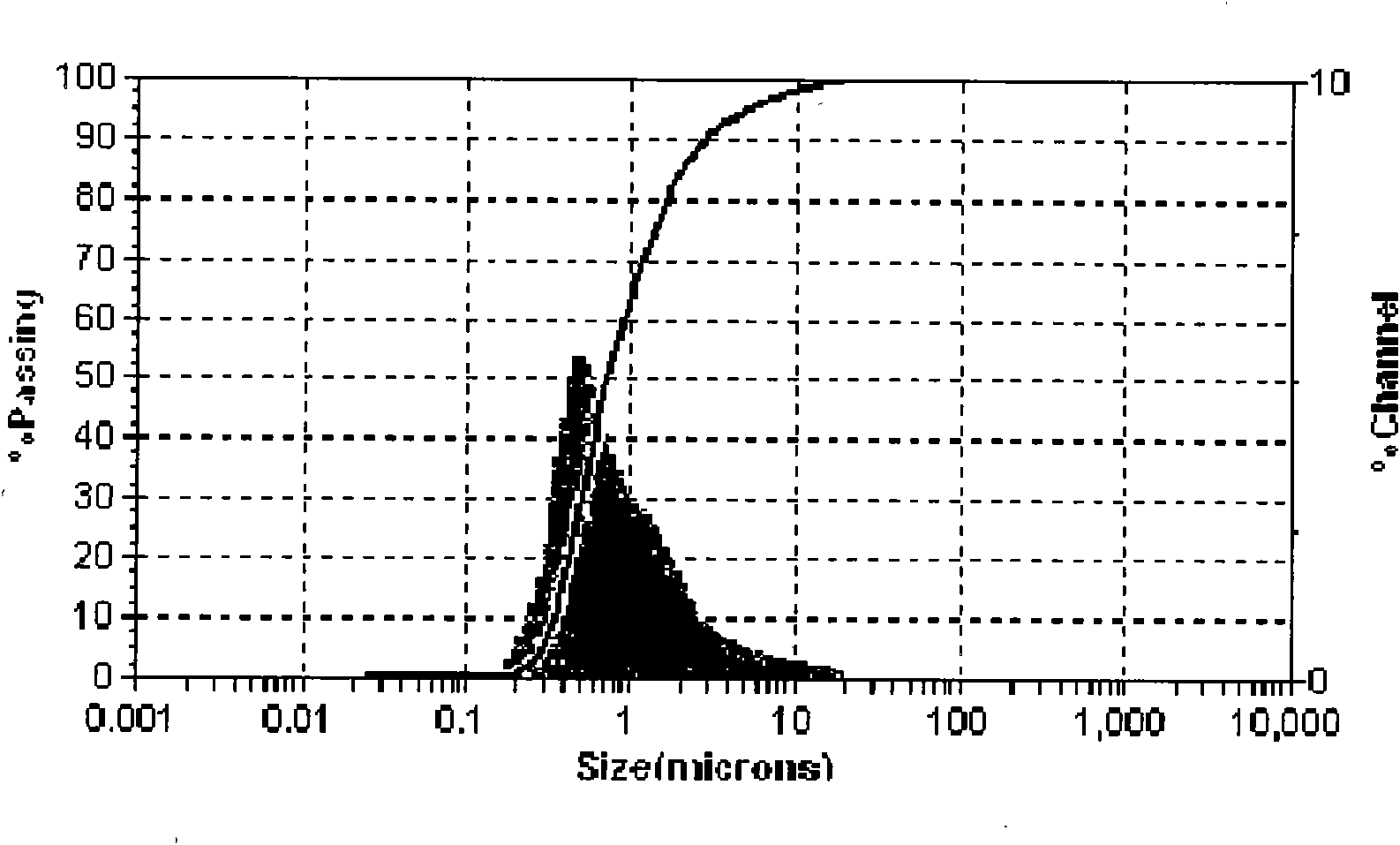

[0054] (1) Preparation of spinel lithium titanate material

[0055] 300g titanium dioxide (TiO 2 ), 116.6g lithium carbonate (Li 2 CO 3 ) was dispersed with absolute ethanol, mixed by ball milling, the speed of ball milling was 300rpm, the time of ball milling was 8h, and dried at 80°C; then placed in a crucible, kept at 800°C for 12h in a high-temperature resistance furnace; then cooled to 500°C for 5h, Cool down at a rate of 1°C / min, keep warm for 6h;

[0056] (2) Preparation of pole piece

[0057] Add 80 parts by weight of lithium titanate composite material, 10 parts by weight of binder polytetrafluoroethylene (PTFE), and 10 parts by weight of conductive agent acetylene black into 110 parts by weight of N-methylpyrrolidone (NMP) solution, and then stir to form Stable and uniform negative electrode slurry. After drying in a vacuum oven at 100° C. for 24 hours, take it out, and press it under a pressure of 4 MPa to form a pole piece with a thickness of 0.03 mm and a dia...

Embodiment 2

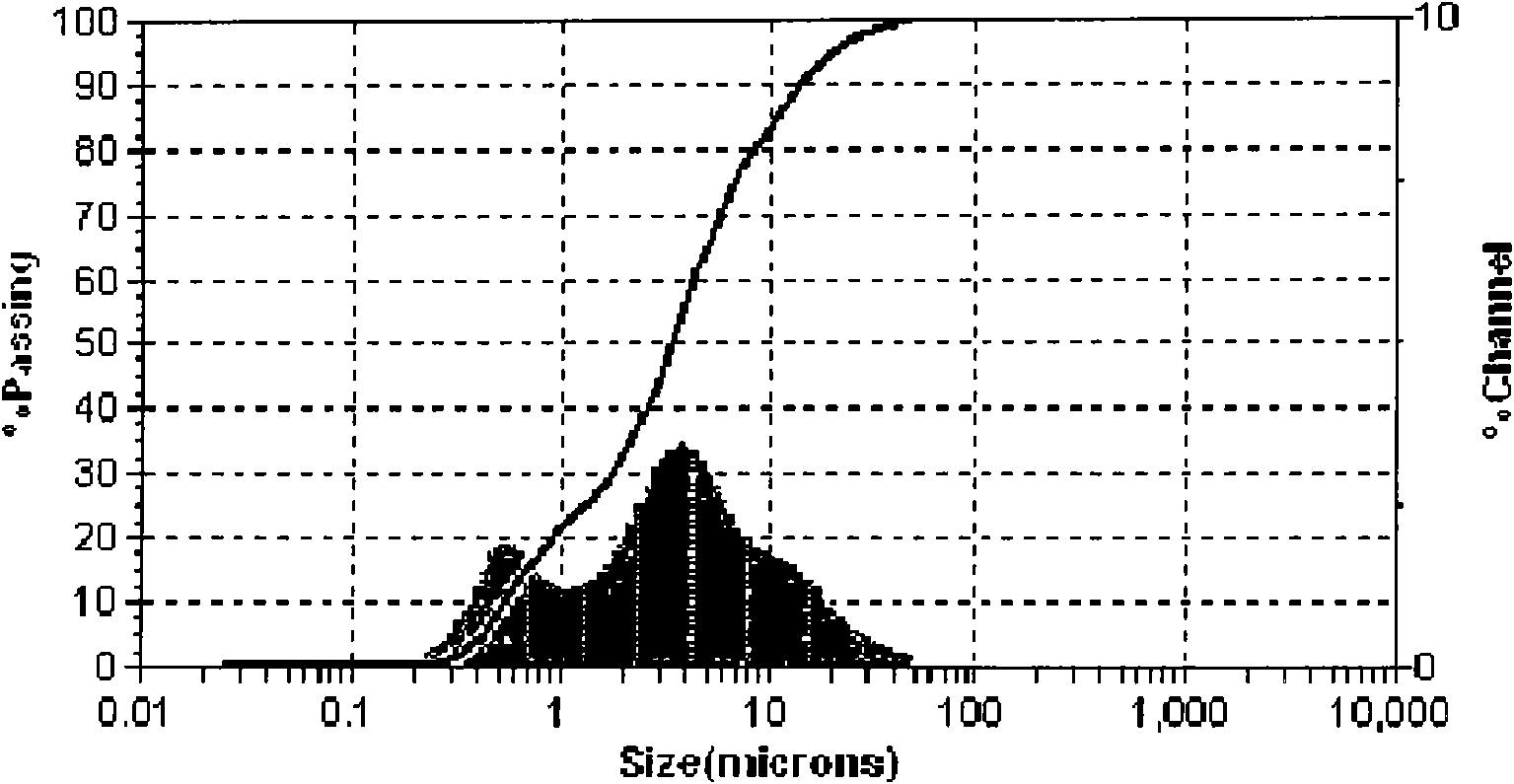

[0062] (1) Preparation of spinel lithium titanate material

[0063] The lithium titanate material was prepared by the same method and steps as in Example 1, except that the cooling rate from the high temperature calcination temperature to the low temperature holding temperature was 0.5°C / min, the low temperature holding temperature was 400°C, and the holding time was 4h; The prepared lithium titanate material is numbered as 2.

[0064] (2) Pole pieces and batteries were prepared in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com