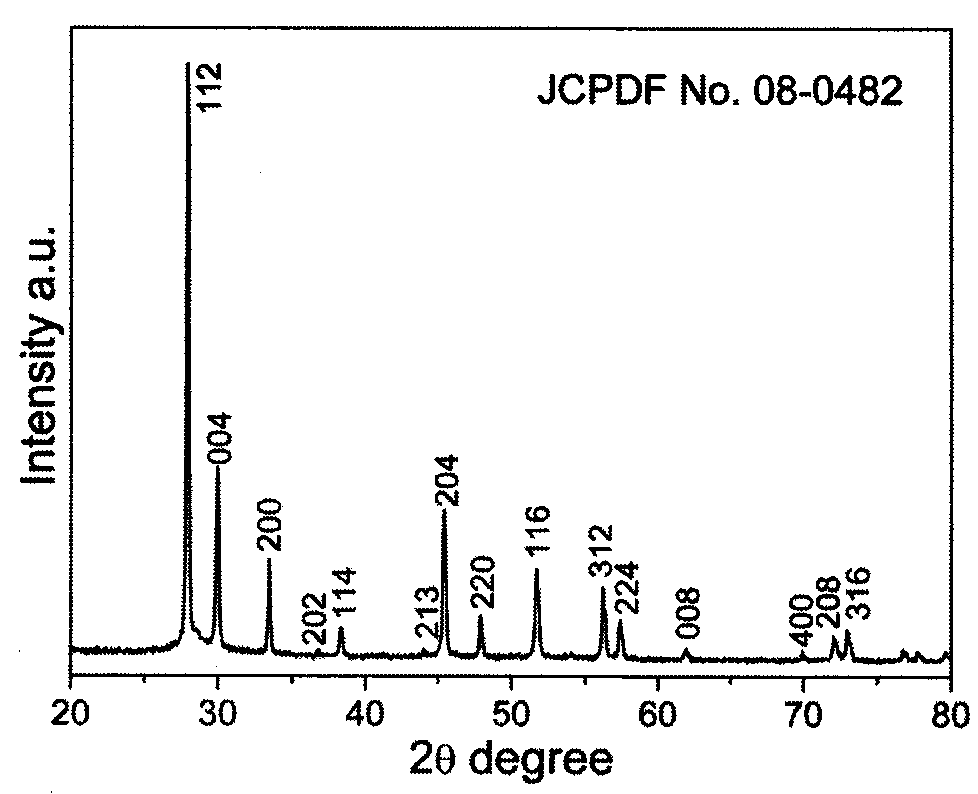

Preparation method for square strontium molybdate nano-plate

A technology of strontium molybdate and nanosheets, which is applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problem that two-dimensional structure molybdate is rarely reported, and achieves low cost, mild and easily controllable conditions, and no energy. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) In a 50ml beaker, add 1.0g cetyltrimethylammonium bromide, 2.0ml n-butanol, 5.0ml n-heptane in turn, and add 0.4ml of 0.05mol / L manganese chloride aqueous solution under magnetic stirring. Stir for 30 minutes to form a homogeneous and transparent microemulsion containing strontium ions.

[0023] 2) Add 1.0ml of cetyltrimethylammonium bromide, 2.0ml of n-butanol, and 5.0ml of n-heptane in a 50ml beaker in sequence, and add 0.4ml of 0.05mol / L sodium molybdate aqueous solution under magnetic stirring. Stir for 30 minutes to form a homogeneous transparent molybdate ion microemulsion.

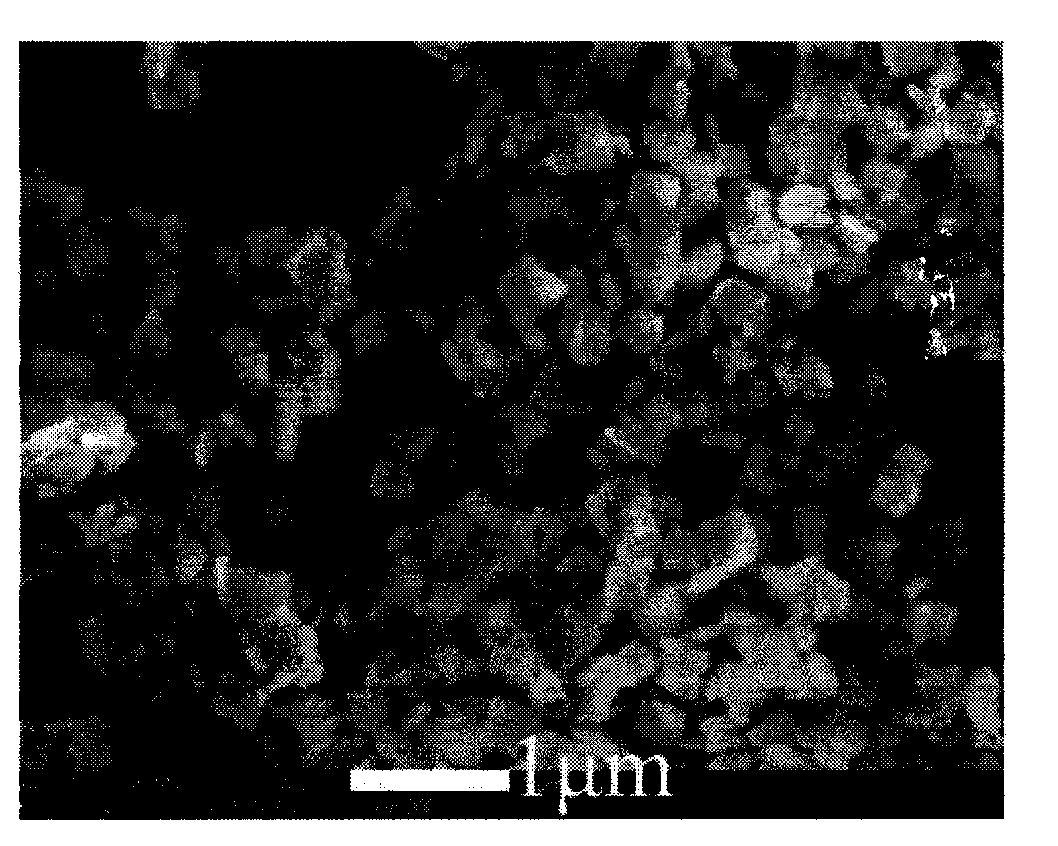

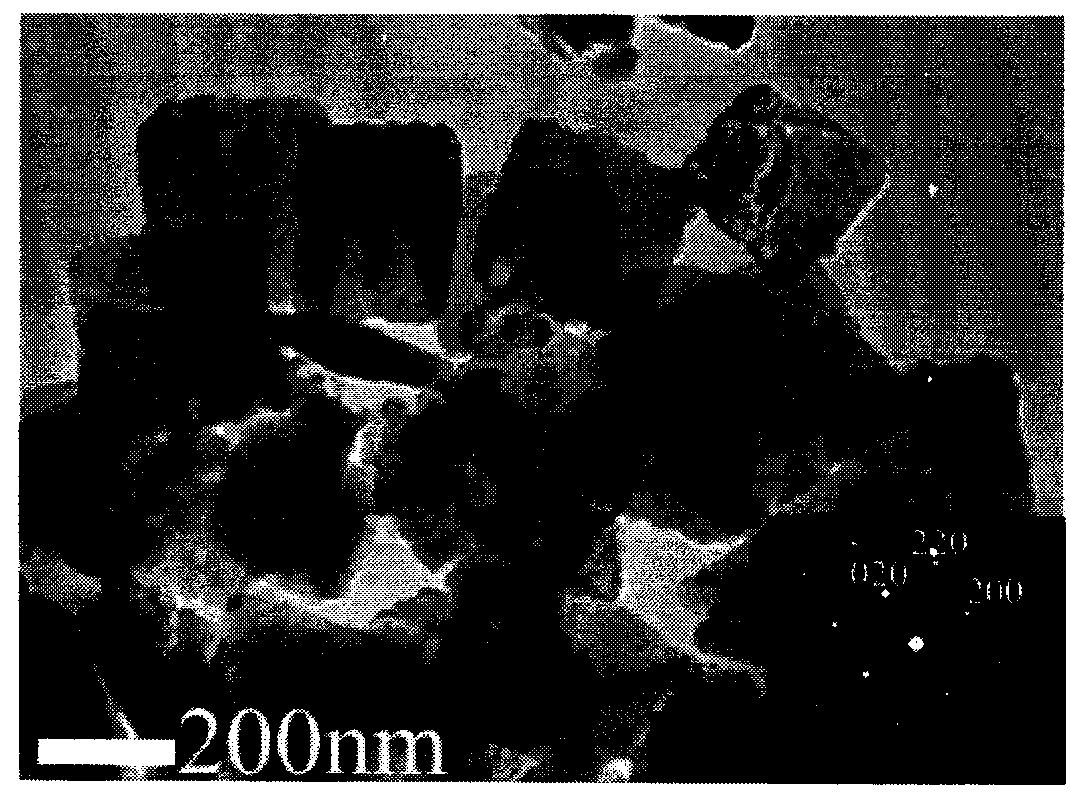

[0024] 3) The above two microemulsions respectively containing strontium chloride and sodium molybdate were slowly mixed under stirring conditions at room temperature, continued to stir for 5 minutes, and left to stand for aging at room temperature for 48 hours, and then mixed with acetone, deionized water and After repeated washing with absolute ethanol, square strontium molybdate nanosh...

Embodiment 2

[0027] 1) In a 50ml beaker, add 1.0g cetyltrimethylammonium bromide, 2.0ml n-butanol, 5.0ml n-heptane successively, and add 1.0ml 0.05mol / L strontium chloride aqueous solution under magnetic stirring. Stir for 30 minutes to form a homogeneous and transparent microemulsion containing strontium ions.

[0028] 2) Add 1.0 g of cetyltrimethylammonium bromide, 2.0 ml of n-butanol, and 5.0 ml of n-heptane in a 50 ml beaker in sequence, and add 1.0 ml of 0.05 mol / L sodium molybdate aqueous solution under magnetic stirring. Stir for 30 minutes to form a homogeneous and transparent microemulsion containing molybdate ions.

[0029] 3) The above two microemulsions respectively containing strontium chloride and sodium molybdate were slowly mixed under stirring conditions at room temperature, continued to stir for 5 minutes, and left to stand for aging at room temperature for 48 hours, and then mixed with acetone, deionized water and The spindle-shaped strontium molybdate nanocrystals can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com