Large size conductive substrate thick circuit write-through device and write-through technology thereof

A conductive substrate and large-format technology, which is applied in the field of repeated direct writing devices and high-precision positioning, can solve the problems of high exposure and etching costs, slow processing speed, and low line yield, and achieve high performance in positioning and repeated direct writing , low wiring cost and large processing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

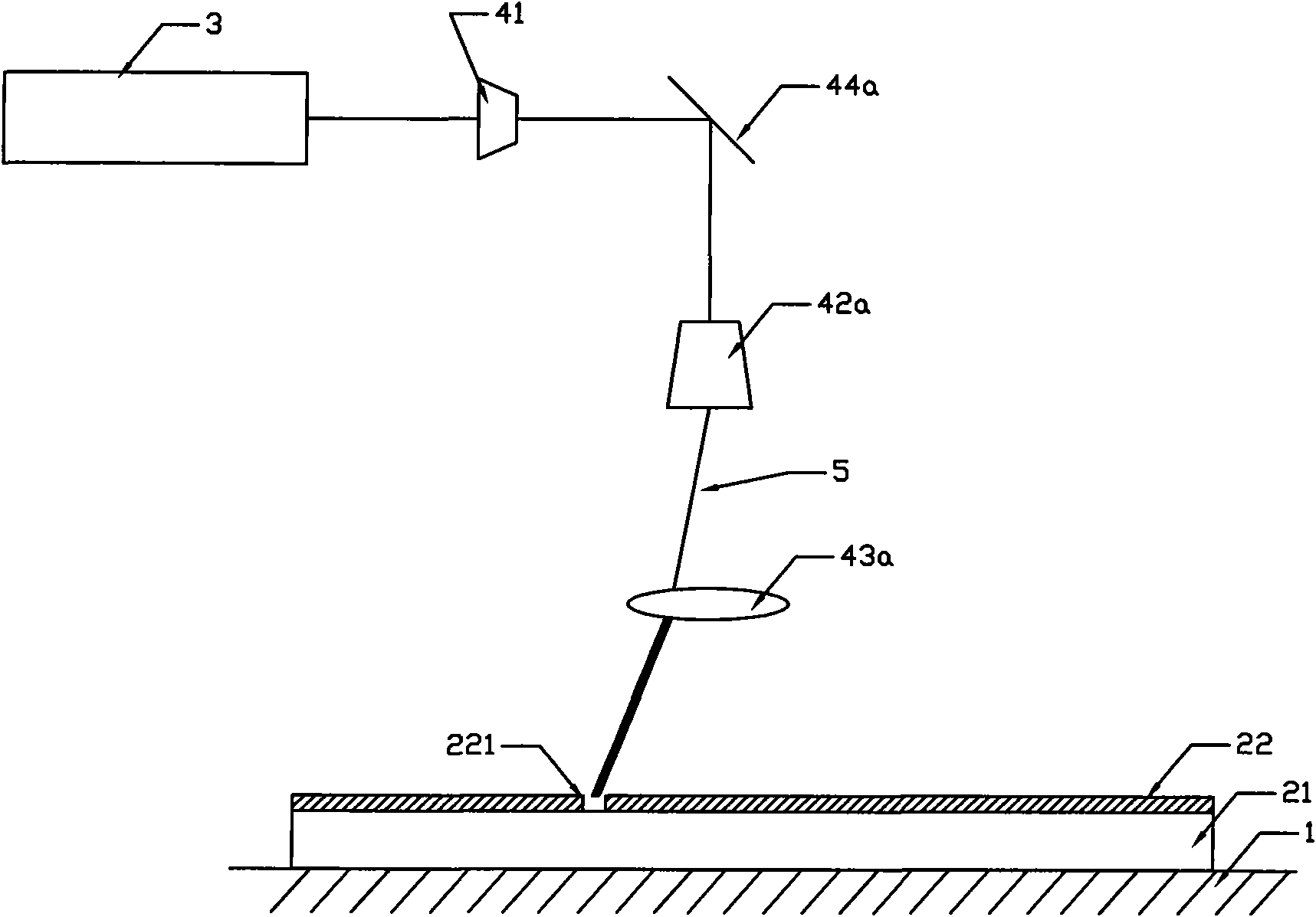

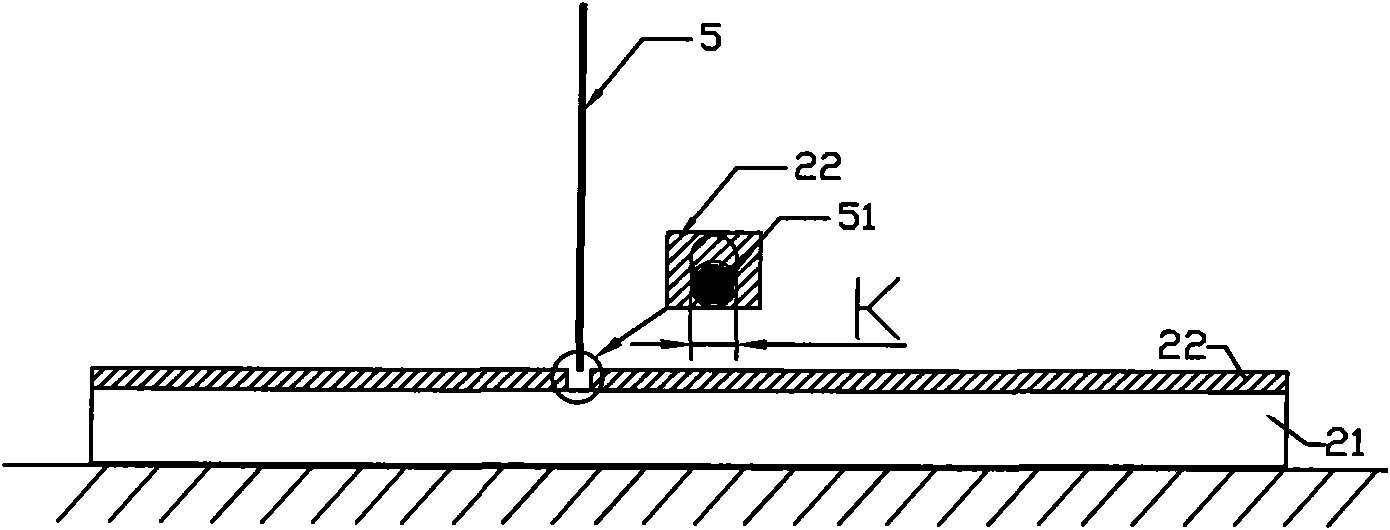

[0026] Such as image 3 As shown, it is a schematic diagram of the principle of the laser direct writing technology based on the thick line direct writing process for large-format conductive substrates in the present invention. The conductive substrate generally consists of a non-conductive substrate 21 and a thin conductive film layer 22. The conductive film layer can be either a conductive plating layer or a conductive coating layer, and can be either a single-layer structure or a multi-layer stack. According to the thickness and energy absorption characteristics of the conductive film layer on the conductive substrate, laser light 5 with specific power and frequency can be selected to irradiate the conductive substrate. The diameter and energy density of the laser spot 51 thus control the etching width K. When the spot focus 51 of the laser 5 moves in a certain direction at a certain speed, a continuous etching line can be drawn on the conductive substrate. Cooperating wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com