Production method of feed colistin sulfate microcapsules

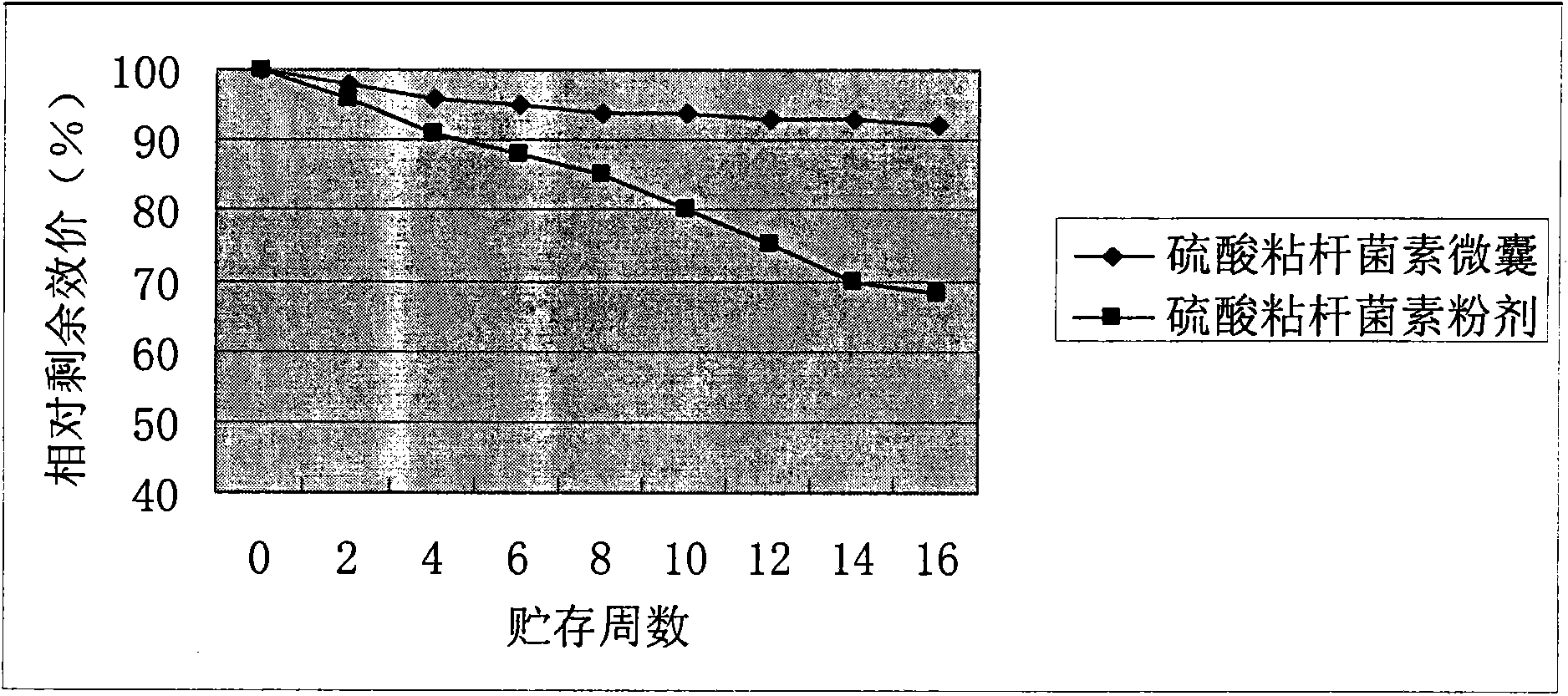

A colistin sulfate and production method technology, applied in animal feed, animal feed, application, etc., can solve the problems of colistin sulfate potency decrease, bioavailability decrease, etc., to prolong drug action time and improve bioavailability Degree, the effect of reducing the cost of medication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

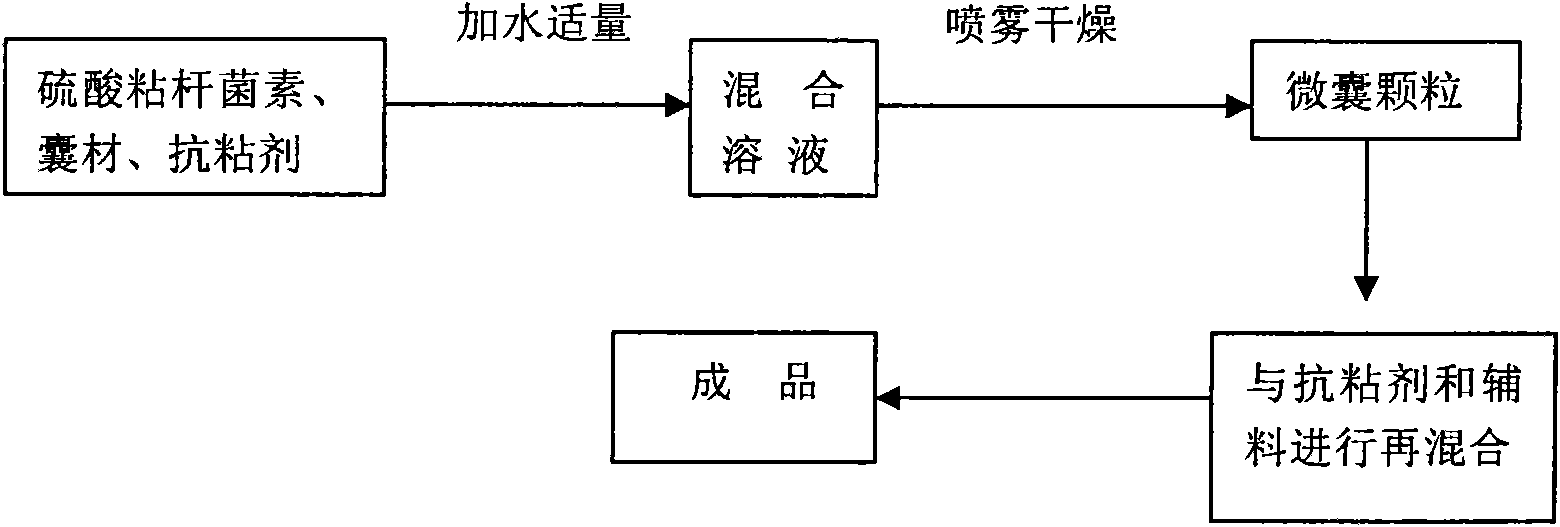

Method used

Image

Examples

Embodiment 1

[0012] Take colistin sulfate, HPMC and magnesium stearate, pass through a 60-mesh sieve respectively, mix evenly with 15kg of colistin sulfate, 10kgHPMC, and 8kg of magnesium stearate, add 67kg of water and mix evenly, and make colistin sulfate and capsule Material mixed solution, the mixed solution of colistin sulfate and capsule material is sprayed and dried in spray equipment, and colistin sulfate microcapsules are obtained. Then add 35 kg of the microcapsules to 5 kg of 60 mesh magnesium stearate and 60 kg of starch for mixing to obtain the final product. The spray drying process conditions are as follows: liquid supply rate: 10ml·min-1; inlet air temperature: 105°C; outlet air temperature: 70°C, atomized gas flow rate: 300L·h-1, moisture after drying: 6%.

Embodiment 2

[0014] Add 10kg HPMC and 9kg magnesium stearate to 16kg colistin sulfate, pass through a 60-mesh sieve and mix evenly, add 65% water and mix evenly to make a mixed solution of colistin sulfate and capsule material, mix colistin sulfate and capsule material The solution is spray-dried in spray equipment to obtain colistin sulfate microcapsules. Then add 35 kg of the microcapsules to 5 kg of 60 mesh magnesium stearate and 60 kg of starch for mixing to obtain the final product. The spray drying process conditions are as follows: liquid supply rate: 10ml·min-1; inlet air temperature: 105°C; outlet air temperature: 70°C, atomized gas flow rate: 300L·h-1, moisture after drying: 6%.

Embodiment 3

[0016] Use 18kg of colistin sulfate plus 11kg of HPMC and 8kg of magnesium stearate, pass through a 60 mesh sieve and mix evenly, add water 63 and mix evenly to make a mixed solution of colistin sulfate and capsule material, and mix solution of colistin sulfate and capsule material Spray equipment is set for spray drying to obtain colistin sulfate microcapsules. Then add 35 kg of the microcapsules to 5 kg of 60 mesh magnesium stearate and 60 kg of starch for mixing to obtain the final product. The spray drying process conditions are as follows: liquid supply rate: 10ml·min-1; inlet air temperature: 105°C; outlet air temperature: 70°C, atomized gas flow rate: 300L·h-1, moisture after drying: 6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com