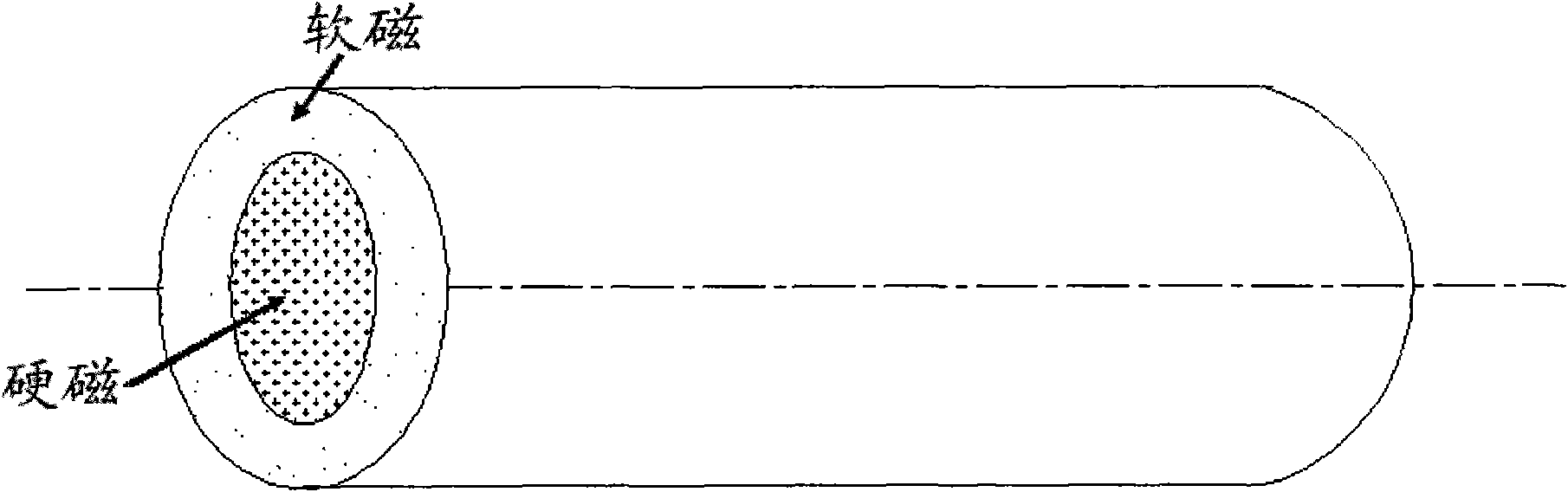

Hard magnetic linear nano coaxial cable wrapped by soft magnetic tube and preparation method thereof

A coaxial cable, nanotechnology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of unfavorable device miniaturization, expensive equipment, low maximum magnetic energy product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

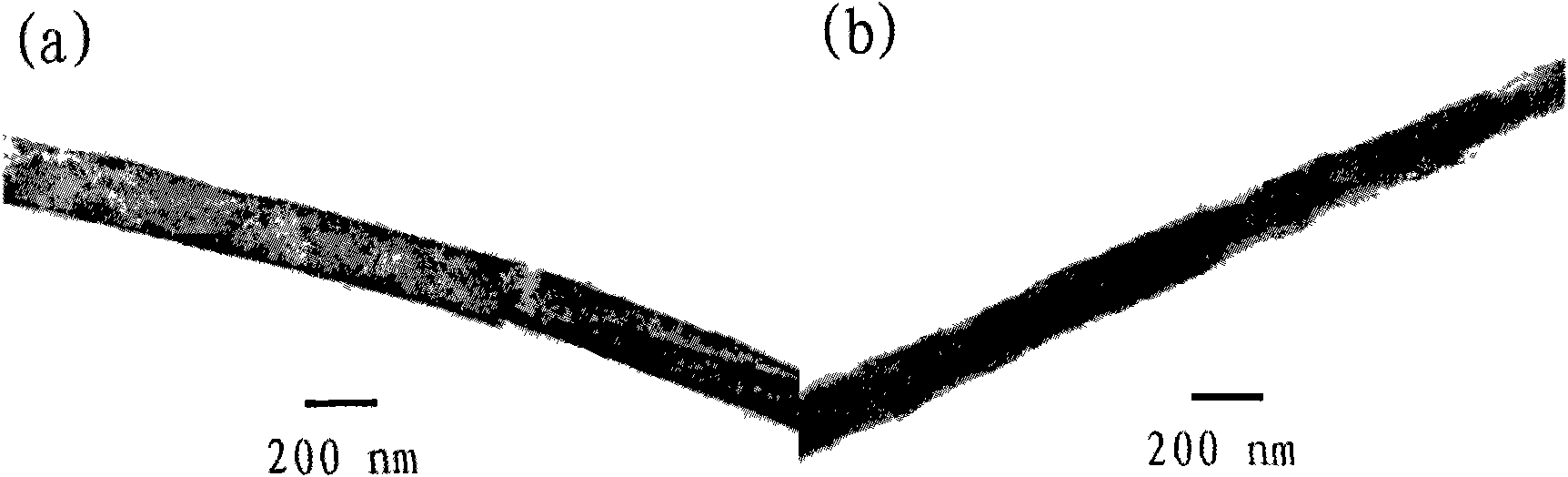

Embodiment

[0017] The high-purity aluminum sheet was annealed in vacuum at 400°C for 4 hours. The annealed aluminum sheet was placed in absolute ethanol for 1 minute and then placed in 0.3 mol / L NaOH for 3 minutes, washed with deionized water, and dried. Put the treated aluminum sheet into a mixture of absolute ethanol and perchloric acid (4:1) and conduct electropolishing for 1.5 minutes with a current of 1A. Take out the aluminum piece and wash it, put it into 0.3mol / L H 3 PO 4 Electrochemical oxidation is carried out in the solution, the oxidation voltage is 120V, and the oxidation time is 3 hours to obtain a porous alumina template. Immerse the alumina template into the prepared saturated solution of ferric nitrate and cobalt nitrate (molar ratio 7:3) for about 30 minutes, take out the template and put it into an oven, and dry it at 60°C. Calcined at 350°C for 3 hours in a tube furnace. Repeat soaking, drying, and calcination process three times. The prepared sample was reduced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com