Method for preparing nitrogenous dopant for preparing czochralski silicon single crystal

A technology of nitrogen doping and Czochralski silicon, applied in the directions of single crystal growth, diffusion/doping, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

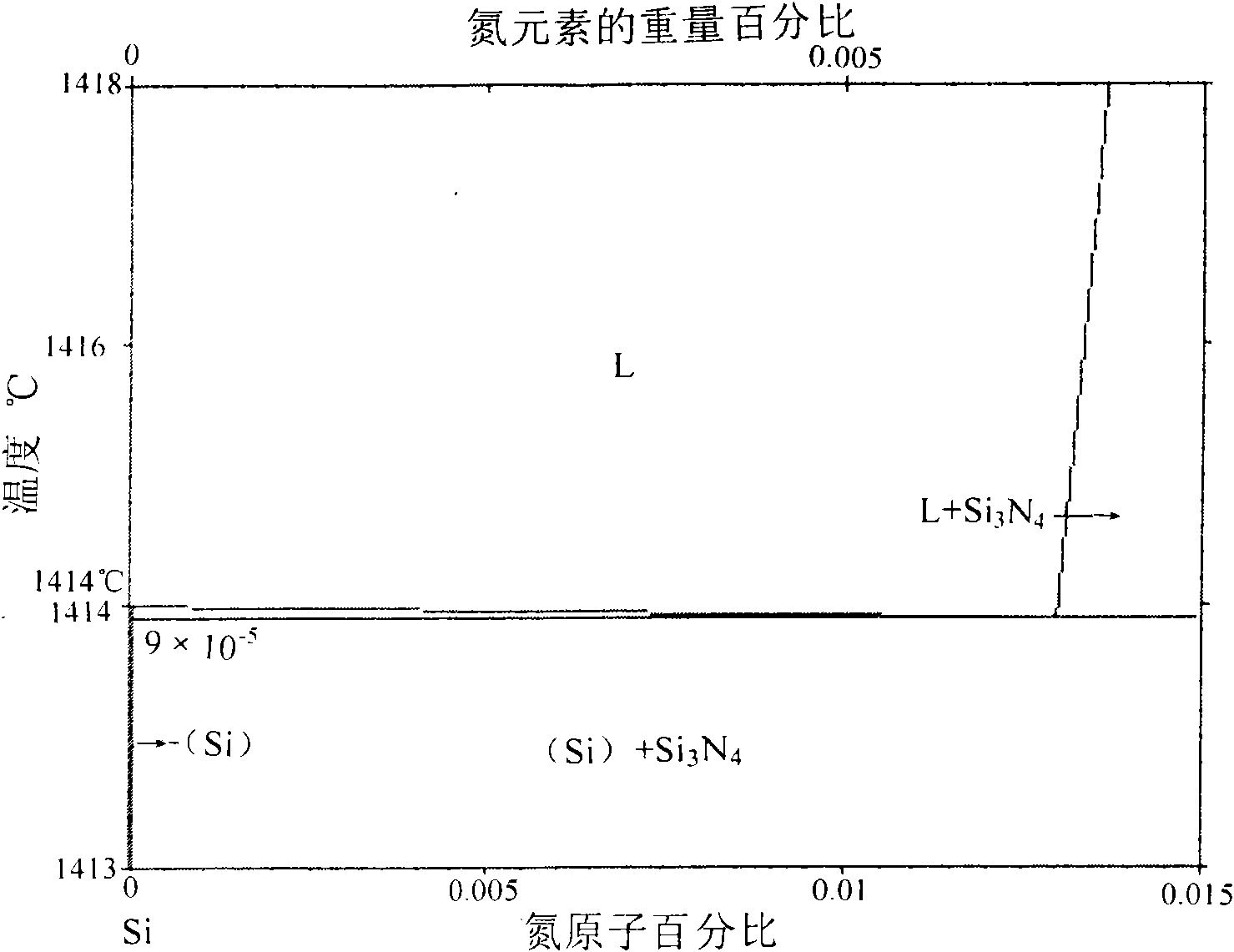

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Put 15kg of polysilicon and 2.5g of silicon nitride powder into a 14-inch quartz crucible, position the quartz crucible at -100mm, keep the crucible at 0 rpm, and heat the heater with a power of 110kw. After the polycrystal is completely melted, turn the crucible at 10rpm and reduce the power of the heater to 105kw to keep the melt surface temperature between 1450°C and 1470°C. After the silicon nitride particles floating on the surface of the melt are all melted, keep the temperature for 1 hour, then raise the crucible to the crucible position of 150mm, and open the flow rate of argon to 100slpm, so that the melt is cooled rapidly. Break the nitrogen-containing dopant obtained by cooling with a silicon carbide hammer into 1~2cm 3 Then soak it in chemically pure hydrofluoric acid for 24 hours to remove the silicon dioxide on the surface of the nitrogen-containing dopant. After soaking, the nitrogen-containing dopant is rinsed with pure water for 5 times, and finally put...

Embodiment 2

[0026] Put 25kg of polysilicon and 4.2g of silicon nitride powder into a 20-inch quartz crucible, position the quartz crucible at the -70mm crucible position, keep the crucible at 0 rpm, and heat the heater with a power of 110kw. After the polycrystal is melted, the crucible is rotated at 12rpm, and the power of the heater is reduced to 107kw to keep the melt surface temperature between 1450°C and 1470°C. After the silicon nitride particles floating on the surface of the melt are completely melted, keep the temperature for 2 hours, then raise the crucible to the crucible position of 300mm, and open the flow rate of argon to 200slpm to cool the melt rapidly. Break the nitrogen-containing dopant obtained by cooling with a silicon carbide hammer into 1~2cm 3 Then soak it in chemically pure hydrofluoric acid for 24 hours to remove the silicon dioxide on the surface of the nitrogen-containing dopant. After soaking, the nitrogen-containing dopant is rinsed with pure water for 5 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com