Preparation method of Si-doped AlN diluted magnetic semiconductor film

A technology of dilute magnetic semiconductor and thin film, which is applied in the direction of magnetic thin film, application of magnetic film to substrate, manufacture/processing of electromagnetic device, etc. Simple, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dry the cleaned n-type Si (100) substrate and put it into a vacuum chamber. The distance between the substrate and the target is 60 mm. The target is Al (80 mm in diameter) with a purity of 99.999% and four A silicon wafer (length 10 mm, width 3 mm), the silicon wafer is symmetrically placed on the Al target, in-situ co-sputtering. Vacuum to 2.0×10 -4 Pa. The working gas in the sputtering process is high-purity nitrogen, the working pressure in the sputtering process is 1.5 Pa, and the substrate temperature is 370°C. Before the official sputtering, the sputtering power was adjusted to 300 W and the target was pre-sputtered for 20 min to remove impurities and oxide layers on the target surface. After the pre-sputtering was completed, the sputtering was started, and the sputtering time was 60 min.

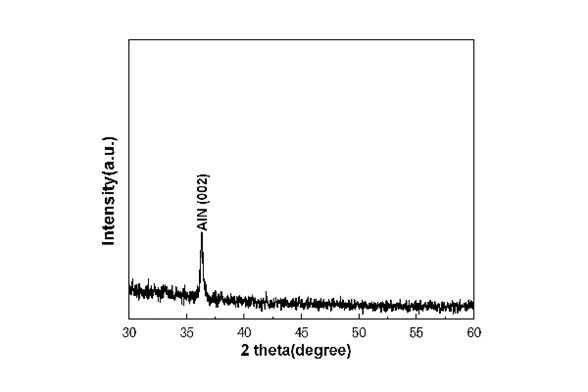

[0025] From figure 1 It can be seen that the prepared film is AlN, and compared with the standard card, it can be seen that the film has a hexagonal wurtzite structure, a...

Embodiment 2

[0027]Dry the cleaned n-type Si (100) substrate and put it into a vacuum chamber. The distance between the substrate and the target is 60 mm. The target is Al (80 mm in diameter) with a purity of 99.999% and seven pieces A silicon wafer (length 10 mm, width 3 mm), the silicon wafer is symmetrically placed on the Al target, in-situ co-sputtering. Vacuum to 2.0×10 -4 Pa. The working gas in the sputtering process is high-purity nitrogen, the working pressure in the sputtering process is 1.5 Pa, and the substrate temperature is 370 °C. Before the official sputtering, the sputtering power was adjusted to 300 W and the target was pre-sputtered for 20 min to remove impurities and oxide layers on the target surface. After the pre-sputtering was completed, the sputtering was started, and the sputtering time was 60 min.

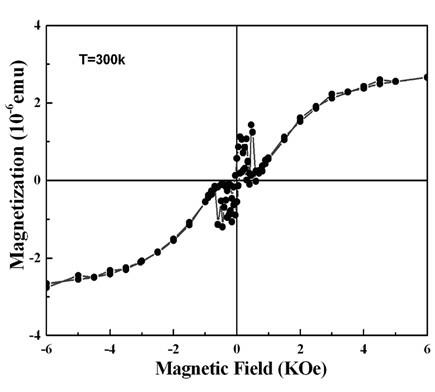

[0028] The M-H curve of the sample is obtained by superconducting quantum fluxmeter, such as image 3 As shown, it can be seen that the sample has obvious ferroma...

Embodiment 3

[0030] Dry the cleaned n-type Si (100) substrate and put it into a vacuum chamber. The distance between the substrate and the target is 60 mm. A silicon wafer (length 10 mm, width 3 mm), the silicon wafer is symmetrically placed on the Al target, in-situ co-sputtering. Vacuum to 2.0×10 -4 Pa. The working gas in the sputtering process is high-purity nitrogen, the working pressure in the sputtering process is 1.5 Pa, and the substrate temperature is 370 °C. Before the official sputtering, the sputtering power was adjusted to 300 W and the target was pre-sputtered for 20 min to remove impurities and oxide layers on the target surface. After the pre-sputtering was completed, the sputtering was started, and the sputtering time was 60 min.

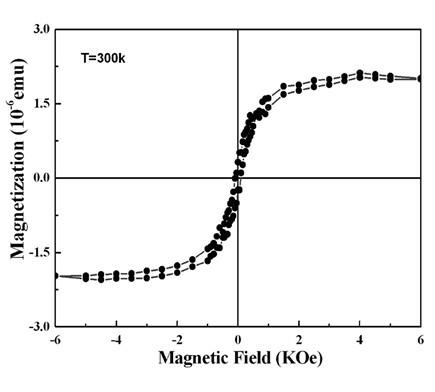

[0031] The M-H curve of the sample is obtained by superconducting quantum fluxmeter, such as Figure 4 As shown, it can be seen that the sample has obvious ferromagnetic properties at room temperature, forming a standard hysteresis loop.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com