Method for preparing Ni-doped AlN-based diluted magnetic semiconductor thin-film material

A technology of dilute magnetic semiconductor and thin film materials, applied in the application of magnetic film to substrate, metal material coating process, ion implantation plating, etc., can solve the problems of high cost and complicated preparation process, and achieve high deposition rate, The preparation process is simple and the doping amount is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dry the cleaned n-type Si(100) substrate and put it into a vacuum chamber. The distance between the substrate and the target is 60mm. sheet (length 10mm, width 1mm), the nickel sheet is symmetrically placed on the Al target, and the Al target and the nickel sheet are co-sputtered. Vacuum down to 2×10 -4 Pa. The working gas in the sputtering process is high-purity nitrogen and high-purity argon, the ratio of argon to nitrogen is 7:3, the working pressure in the sputtering process is 1.5Pa, and the temperature of the substrate is 370°C. Before the official sputtering, adjust the sputtering power to 200W to pre-sputter the target for 20 minutes to remove impurities and oxide layers on the target surface. After the pre-sputtering is completed, the sputtering power is adjusted to 300W, and the sputtering is started, and the sputtering time is 60min.

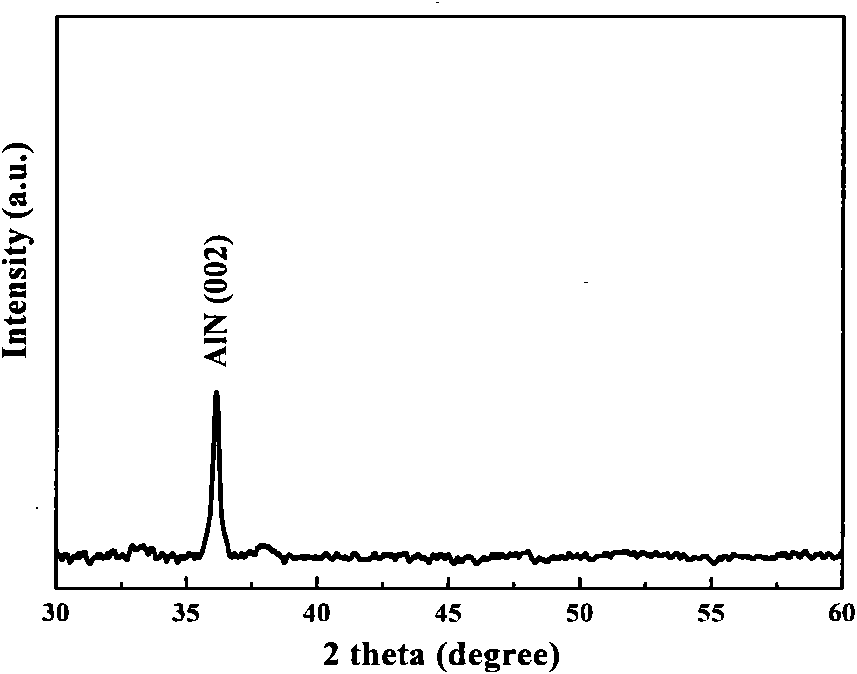

[0028] From figure 1 It can be seen that the prepared thin film is AlN, and the M-H curve of the sample is obtained by a ...

Embodiment 2

[0030] Dry the cleaned n-type Si (100) substrate and put it into a vacuum chamber. The distance between the substrate and the target is 60 mm. The target is Al (80 mm in diameter) with a purity of 99.999% and six pieces of nickel with a purity of 99.99%. sheet (length 10mm, width 1mm), the nickel sheet is symmetrically placed on the Al target, and the Al target and the nickel sheet are co-sputtered. Vacuum down to 2×10 -4 Pa. The working gas in the sputtering process is high-purity nitrogen and high-purity argon, the ratio of argon to nitrogen is 7:3, the working pressure in the sputtering process is 1.5Pa, and the temperature of the substrate is 370°C. Before the official sputtering, adjust the sputtering power to 200W to pre-sputter the target for 20 minutes to remove impurities and oxide layers on the target surface. After the pre-sputtering is completed, the sputtering power is adjusted to 300W, and the sputtering is started, and the sputtering time is 60min.

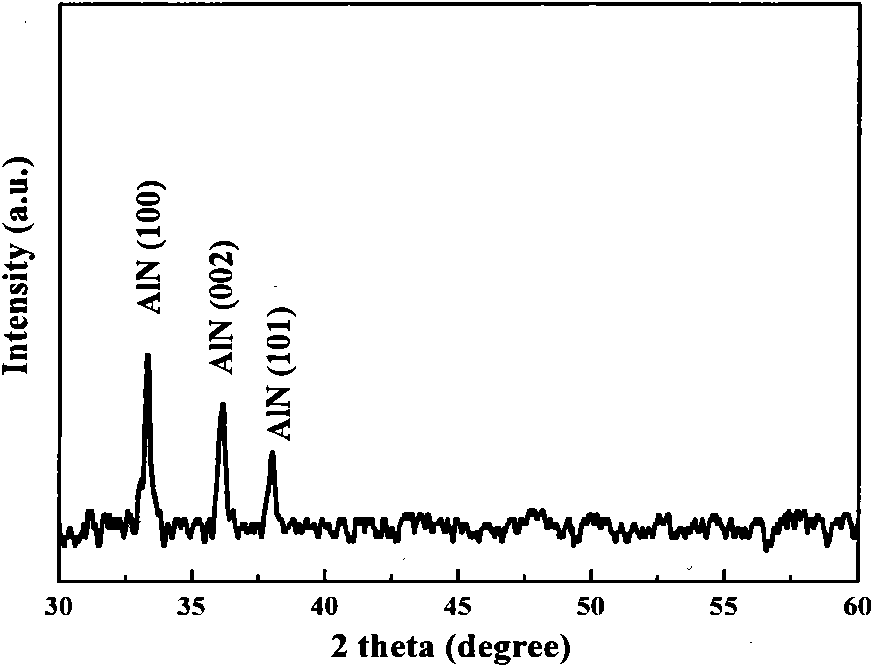

[0031] F...

Embodiment 3

[0033] Dry the cleaned n-type Si (100) substrate and put it into a vacuum chamber. The distance between the substrate and the target is 60mm. The target is Al (80mm in diameter) with a purity of 99.999% and nine pieces of nickel with a purity of 99.99%. sheet (length 10mm, width 1mm), the nickel sheet is symmetrically placed on the Al target, and the Al target and the nickel sheet are co-sputtered. Vacuum down to 2×10 -4 Pa. The working gas in the sputtering process is high-purity nitrogen and high-purity argon, the ratio of argon to nitrogen is 7:3, the working pressure in the sputtering process is 1.5Pa, and the temperature of the substrate is 370°C. Before the official sputtering, adjust the sputtering power to 200W to pre-sputter the target for 20 minutes to remove impurities and oxide layers on the target surface. After the pre-sputtering is completed, the sputtering power is adjusted to 300W, and the sputtering is started, and the sputtering time is 60min.

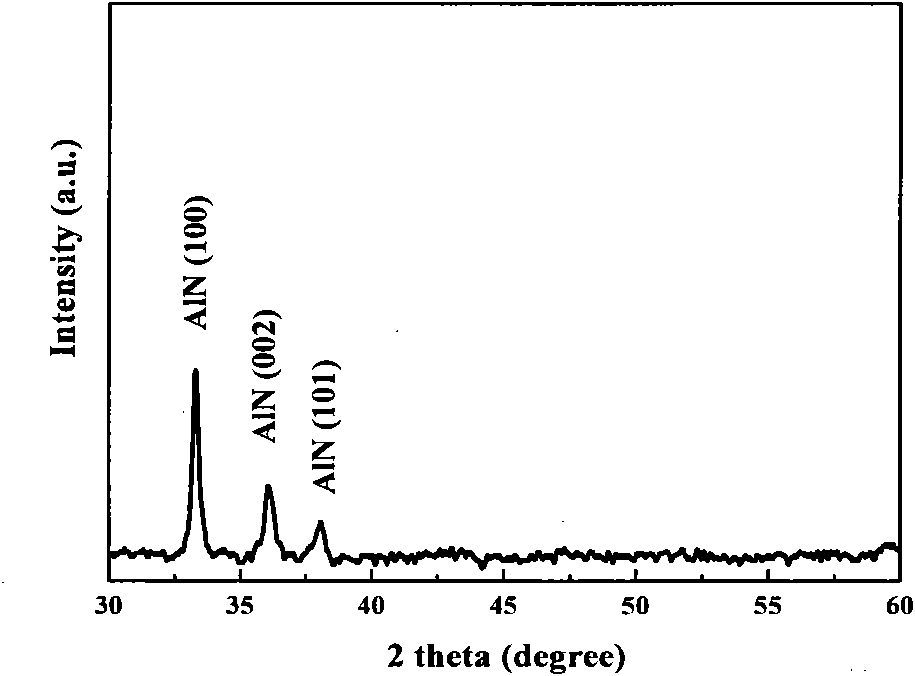

[0034] Fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com