A preparation method of a nitrogen-sulfur co-doped three-dimensional graphene foam electrode active material

A graphene foam, nitrogen-sulfur co-doping technology, applied in graphene, battery electrodes, circuits, etc., to achieve the effects of simple operation, low cost, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) First, disperse 50mg of graphene oxide in a mixed solvent of 70ml of deionized water and 10ml of ethanol to obtain a graphene oxide dispersion. After ultrasonic stripping of graphene oxide, add 0.03g of melamine and 0.04g of thiocyanate in sequence , Stir at 80°C until completely dissolved.

[0022] (2) Immerse 30*60*0.5mm nickel foam into the liquid of (1), and then put it into a 100ml polytetrafluoroethylene reactor for hydrothermal reaction. The hydrothermal reaction time is 4 hours, and the hydrothermal temperature is 100°C.

[0023] (3) After freeze-drying, the hydrothermal product was placed in a tube furnace, and the temperature was raised to 500°C at a rate of 2°C / min for 5 hours under an atmosphere protected by argon.

[0024] (4) Immerse the product in 5% dilute hydrochloric acid, stir magnetically at 80°C for 12 hours, and etch off the nickel foam. Then centrifuged and washed 6 times, dried to obtain the sample.

Embodiment 2

[0026] (1) First, disperse 100mg of graphene oxide in a mixed solvent of 25ml of deionized water and 25ml of ethanol to obtain a graphene oxide dispersion, then add 0.03g of melamine and 0.04g of thiocyanate in turn, and stir at 80°C until completely dissolve.

[0027] (2) Immerse 30*60*1mm nickel foam into the liquid of (1), and then put it into a 100ml polytetrafluoroethylene reactor for hydrothermal reaction. The hydrothermal reaction time is 24 hours, and the hydrothermal temperature is 150°C.

[0028] (3) After freeze-drying, the hydrothermal product was placed in a tube furnace, and the temperature was raised to 600°C at a rate of 5°C / min for 2 hours under an argon-protected atmosphere.

[0029] (4) Immerse the product in 5% dilute hydrochloric acid, stir magnetically at 80°C for 12 hours, and etch off the nickel foam. Then centrifuged and washed 6 times, dried to obtain the sample.

Embodiment 3

[0031] (1) First, disperse 100mg of graphene oxide in a mixed solvent of 50ml of deionized water and 10ml of ethanol to obtain a graphene oxide dispersion, then add 0.12g of melamine and 0.17g of thiocyanate in sequence, and stir at 80°C until completely dissolve.

[0032] (2) Immerse 30*60*2mm nickel foam into the liquid of (1), and then put it into a 100ml polytetrafluoroethylene reactor for hydrothermal reaction. The hydrothermal reaction time is 36 hours, and the hydrothermal temperature is 200°C.

[0033] (3) After freeze-drying, the hydrothermal product was placed in a tube furnace, and the temperature was raised to 800°C at a rate of 10°C / min under an argon-protected atmosphere for 1 hour.

[0034] (4) Immerse the product in 5% dilute hydrochloric acid, stir magnetically at 80°C for 12 hours, and etch off the nickel foam. Then centrifuged and washed 6 times, dried to obtain the sample.

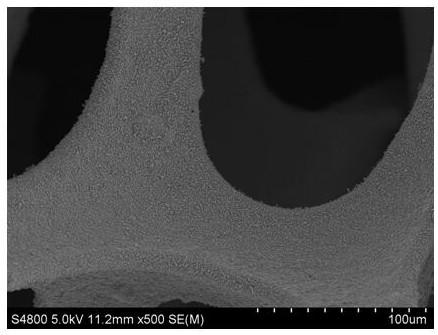

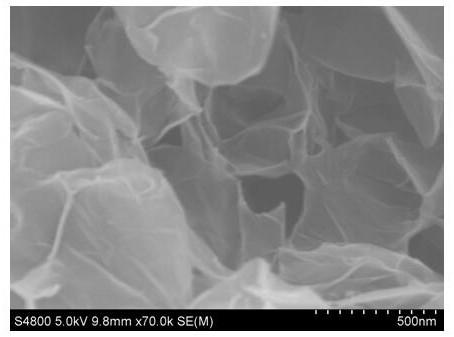

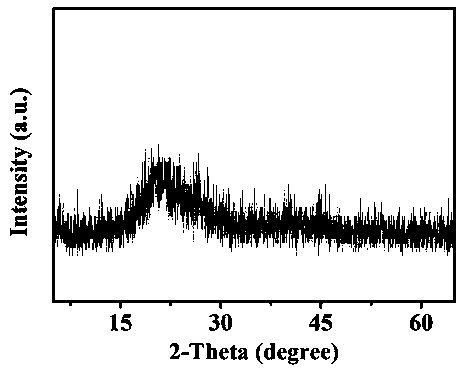

[0035] Refer to attached Figure 1~3 , figure 1 Low magnification scanning ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com