Method for formation of multi-layered coating film, and coated article

A film coating and coating technology, which is applied to the device, coating, special surface and other directions of coating liquid on the surface. It can solve the problems of limited usable time, difficulty in shortening steps, poor adhesion between layers, etc., and achieve excellent gloss. , Adhesion improvement, excellent transparency and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

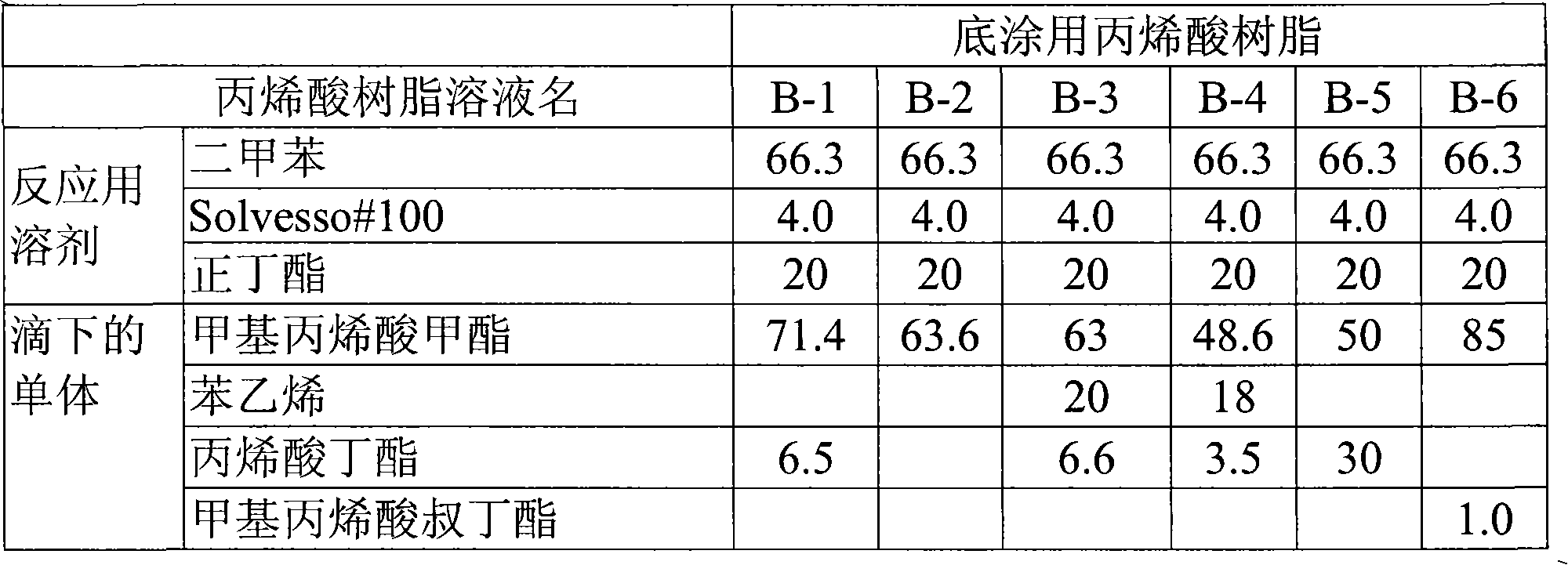

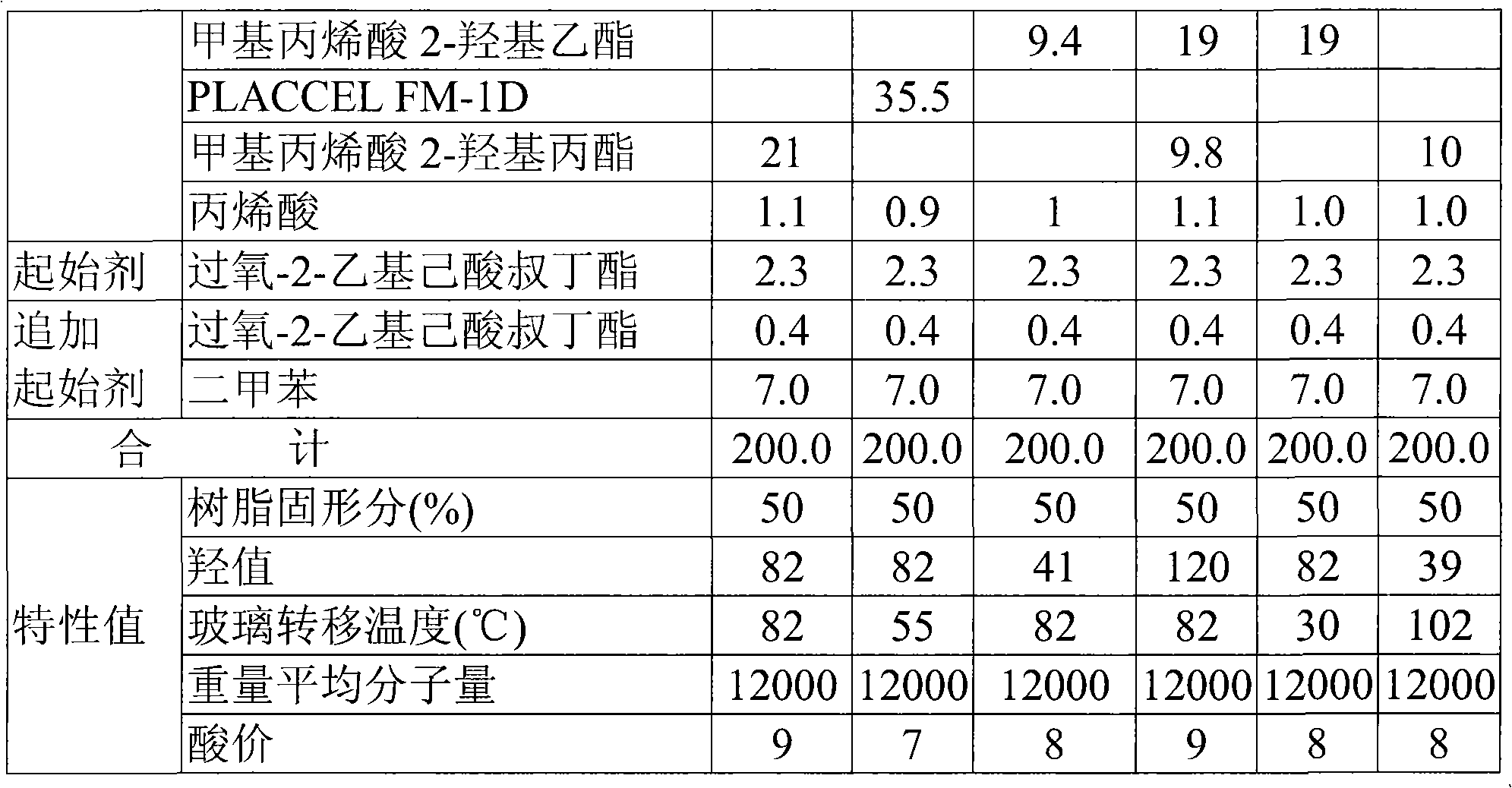

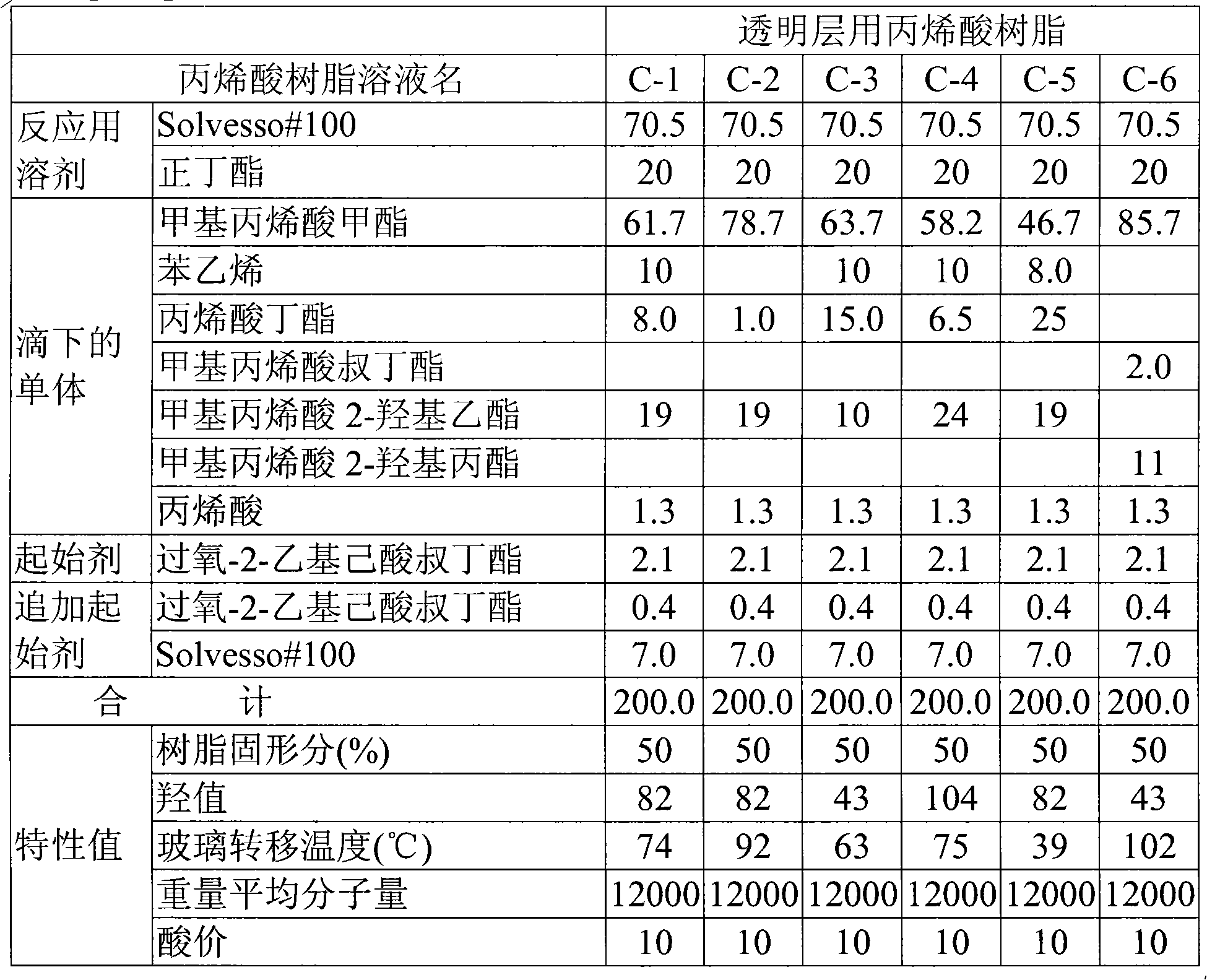

[0110] The present invention will be described more specifically with reference to Production Examples, Examples, and Comparative Examples below. In addition, "parts" and "%" mean "parts by mass" and "% by mass", respectively, unless otherwise specified.

[0111]

[0112] In a four-necked flask equipped with a thermometer, a stirrer, a circulating cooler, and a dropping funnel, add 66.3 parts of xylene, 4 parts of Solvesso#100 (trade name, manufactured by Esso Chemical Co., Ltd., aromatic light oil) , 20 parts of n-butanol. The contents contained in this four-necked flask were heated up to 140°C. Next, in this four-necked flask, a mixture of 71.4 parts of methyl methacrylate, 6.5 parts of butyl acrylate, 21 parts of 2-hydroxypropyl methacrylate, 1.1 parts of acrylic acid polymerizable monomer and 2.3 parts of starting The mixture of tert-butyl peroxy-2-ethylhexanoate (t-butylperoxy-2-ethylhexanoate) was dropped from the dropping funnel at constant speed for 2 hours. After...

Embodiment 1

[0175]In the manganese phosphate series chemical conversion treatment agent (magbond for magnesium alloy (magbond) P10: trade name, Japan Parker Processing Co., Ltd. manufacture) to implement the commercially available magnesium alloy (Mg-Al-Zn series alloy, equivalent to The surface of AZ91D according to the JIS standard) was coated with (Bellfine Primer No.5000) (trade name, manufactured by BASF Coatings Co., Ltd., epoxy resin / melamine cross-linking primer) by air spraying until the dry coating The film thickness was 20 μm, and a primer coating film was formed. The primer coating film was baked at 160°C for 20 minutes. Next, the viscosity of the base coating material BC-1 was adjusted to 12 seconds (20° C.) measured with an Iwata viscosity cup NK2 by adding a mixed dilution solvent (xylene / butyl acetate=50 / 50 mixed solution). On the surface of the above-mentioned primer, the primer paint BC-1 with adjusted viscosity was applied by air spraying until the dry film thickness w...

Embodiment 2~5

[0179] (Examples 2-5, Comparative Examples 1-14)

[0180] Except having replaced it with the primer and clear paint shown in Tables 5-7, it carried out similarly to Example 1, and produced the test panel. The test results are shown in Tables 5 to 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com