Method for preparing lactobacillus microcapsules

A technology of lactic acid bacteria microcapsules and microcapsules is applied in the directions of microcapsule preparations, microsphere preparation, food forming, etc., and can solve the problems of low yield of lactic acid bacteria microcapsules, uneven dispersion of lactic acid bacteria, high mortality of lactic acid bacteria, and achieve food safety. High performance, avoiding uneven dispersion, and reducing serum cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

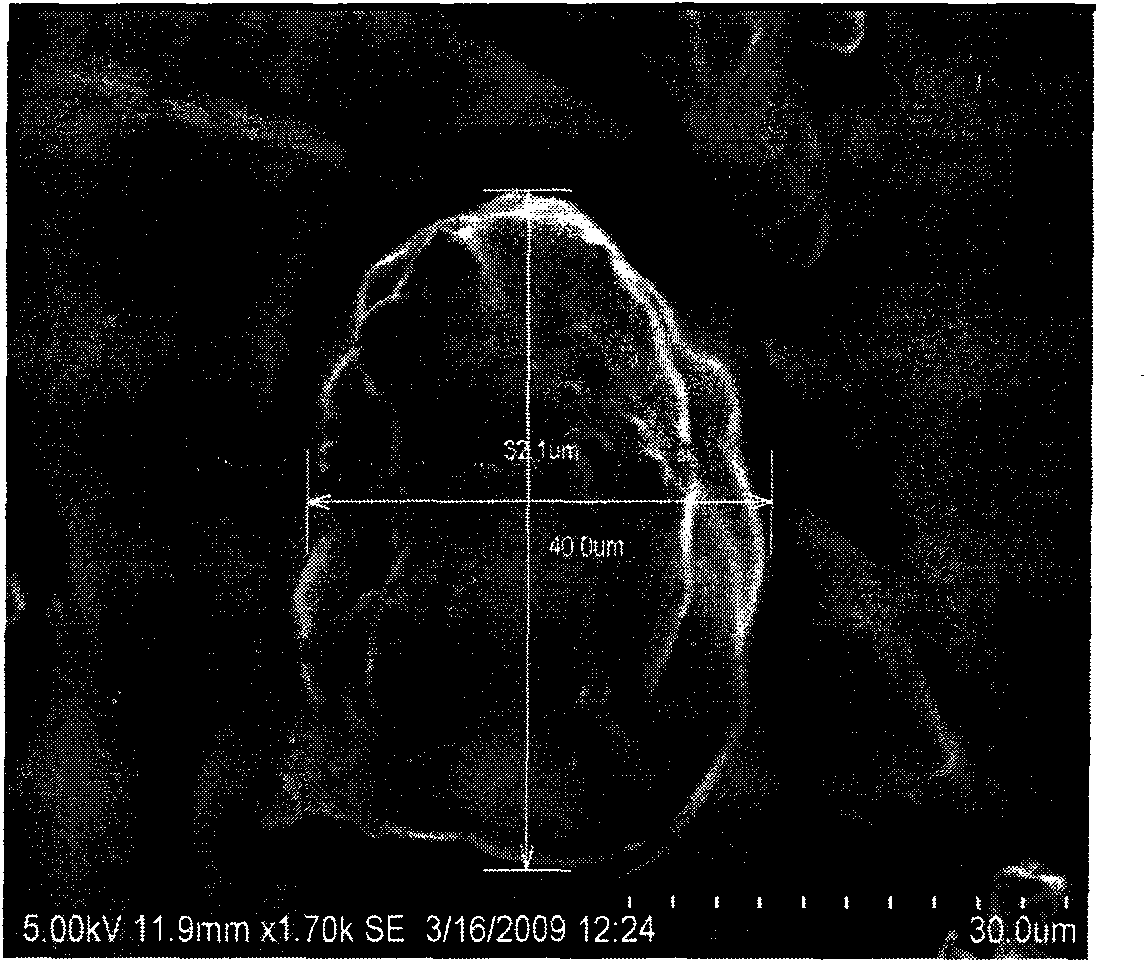

[0015] Specific embodiment one: the lactic acid bacteria microcapsules of this embodiment are prepared according to the following steps: 1. Mix the microcapsule core material and the microcapsule wall material evenly according to the volume ratio of 1:2 to obtain a mixed solution, wherein the microcapsule core material is added Protective agent and prebiotic lactic acid bacteria liquid, the microcapsule wall material is a sodium alginate solution with an emulsifier added, the mass concentration of sodium alginate in the microcapsule wall material is 1.8% to 2.2%, and the emulsifier in the microcapsule wall material It is Tween-20, the mass concentration of emulsifier is 0.09%~0.11%; 2, the mixed liquid that step 1 obtains is added dropwise in the salad oil that contains stearic acid and emulsifier Span-80, and at 37 ℃, rotating speed Under the condition of 1080~1140r / min, it is emulsified for 14~16min to form a primary emulsion, wherein the volume ratio of the dripping amount o...

specific Embodiment approach 2

[0027] Specific embodiment two: the lactic acid bacteria microcapsules of this embodiment are prepared according to the following steps: 1. Mix the microcapsule core material and the microcapsule wall material evenly according to the volume ratio of 1:2 to obtain a mixed solution, wherein the microcapsule core material is added Protective agent and prebiotic lactic acid bacteria liquid, the microcapsule wall material is sodium alginate solution with emulsifier added, the mass concentration of sodium alginate in the microcapsule wall material is 2%, and the emulsifier in the microcapsule wall material is Tween- 20. The mass concentration of the emulsifier is 0.1%; 2. Add the mixed liquid obtained in step 1 dropwise to the salad oil containing stearic acid and emulsifier Span-80, and heat it under the conditions of 37°C and 1100r / min Lower emulsification for 15min forms primary emulsion, wherein the volume ratio of the amount of mixed solution added to the salad oil is 1:2, the m...

specific Embodiment approach 3

[0059] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the concentration of the lactic acid bacteria bacterial liquid in step one is 0.46×10 9 cfu / mL Lb.paracasei HD1.7 bacteria liquid. Other steps and parameters are the same as those in Embodiment 1 or 2.

[0060] In this embodiment, Lactobacillus paracasei HD1.7 (Lb.paracasei HD1.7) has been preserved in the China Type Culture Collection Center, the preservation number is CCTCC M205015, and it has a Chinese invention patent "peptide natural microbial preservative producing bacteria and Applications and preparation methods of preservatives" (publication number CN1670184A, published on September 21, 2005). Lactobacillus paracasei HD1.7 (Lb.paracasei HD1.7) was isolated in 2002 from the fermentation broth of L-lactic acid bacteria pickled sauerkraut by the Key Laboratory of Microbiology, College of Life Sciences, Heilongjiang University.

[0061] Lb.paracasei HD1.7 belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com