Bacterial strain for repairing chromium slag contaminated site

A site remediation and strain technology, applied in the field of chromium-reducing functional bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1: Separation, purification and domestication of the chromium reducing bacteria of the present invention

[0012] Collect the soil under the chromium residue storage site of Hunan Ferroalloy Plant, weigh 10g of the chromium residue soil into a 150mL sterilized Erlenmeyer flask, add 10mL sterilized liquid medium (5g / L sodium lactate, 5g / L yeast extract and 2g / L Sodium chloride, the rest is water, use 5mol / L NaOH to adjust pH=9.5~9.8), culture in 30℃ incubator for 4 days. Then take 1mL of mud and dilute it to 10 -3 , 10 -4 , 10 -5 , 10 -6 , 10 -7 , 10 -8 , Using a pipette from 10 -6 , 10 -7 And 10 -8 Take 0.1 mL of the diluent and place it with 250mg / L Cr(VI) (in K 2 Cr 2 O 7 The solution is used as the solid medium for the chromium source), and the solid medium is composed of 5 g / L sodium lactate, 5 g / L yeast extract, 2 g / L sodium chloride, and 15 g / L agar. Fully spread with a triangular rod, and place the plate upside down in a 30°C incubator for 4 days. Use a ste...

Embodiment 2

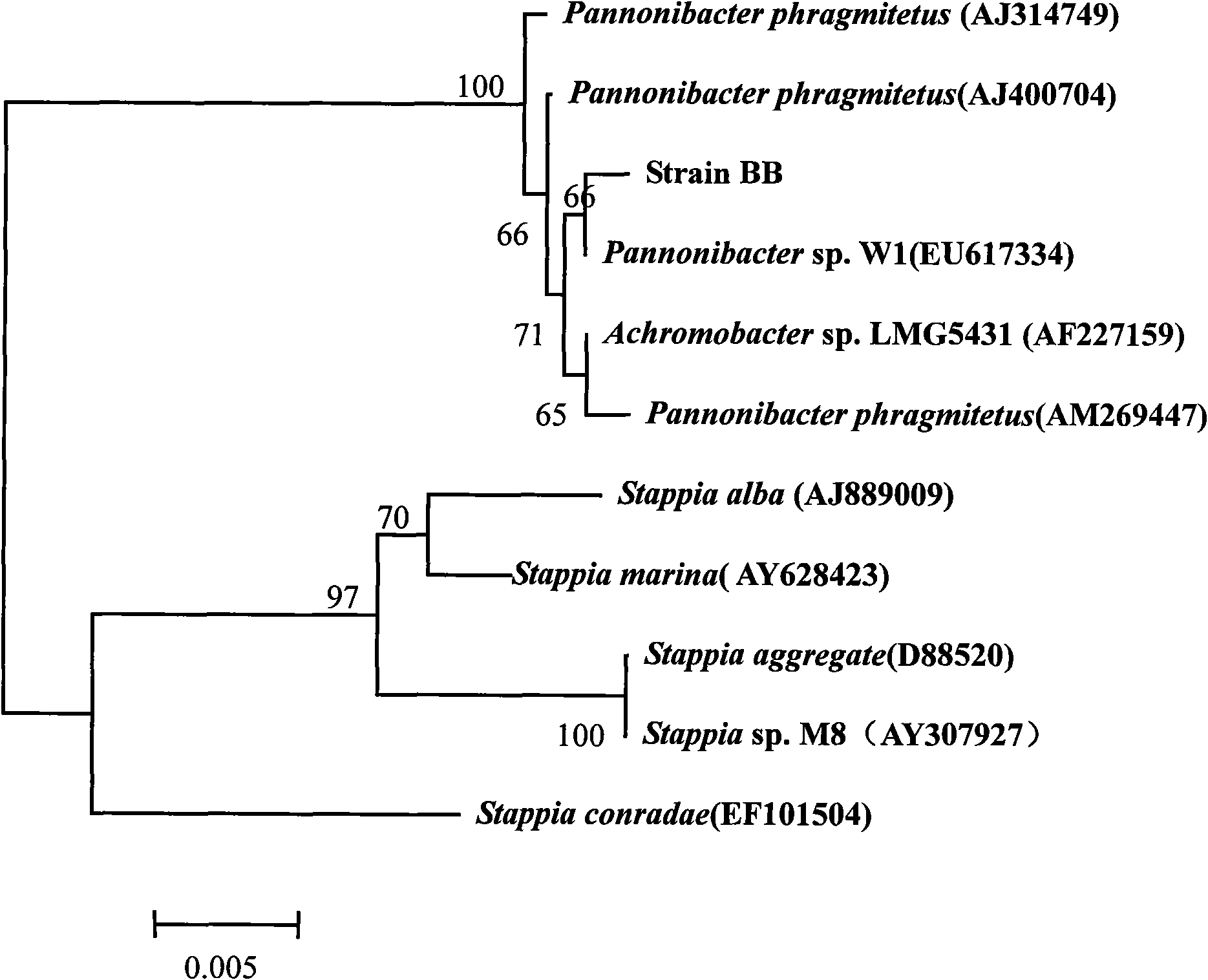

[0015] Example 2: Bacteriological characteristics and biological identification of strains

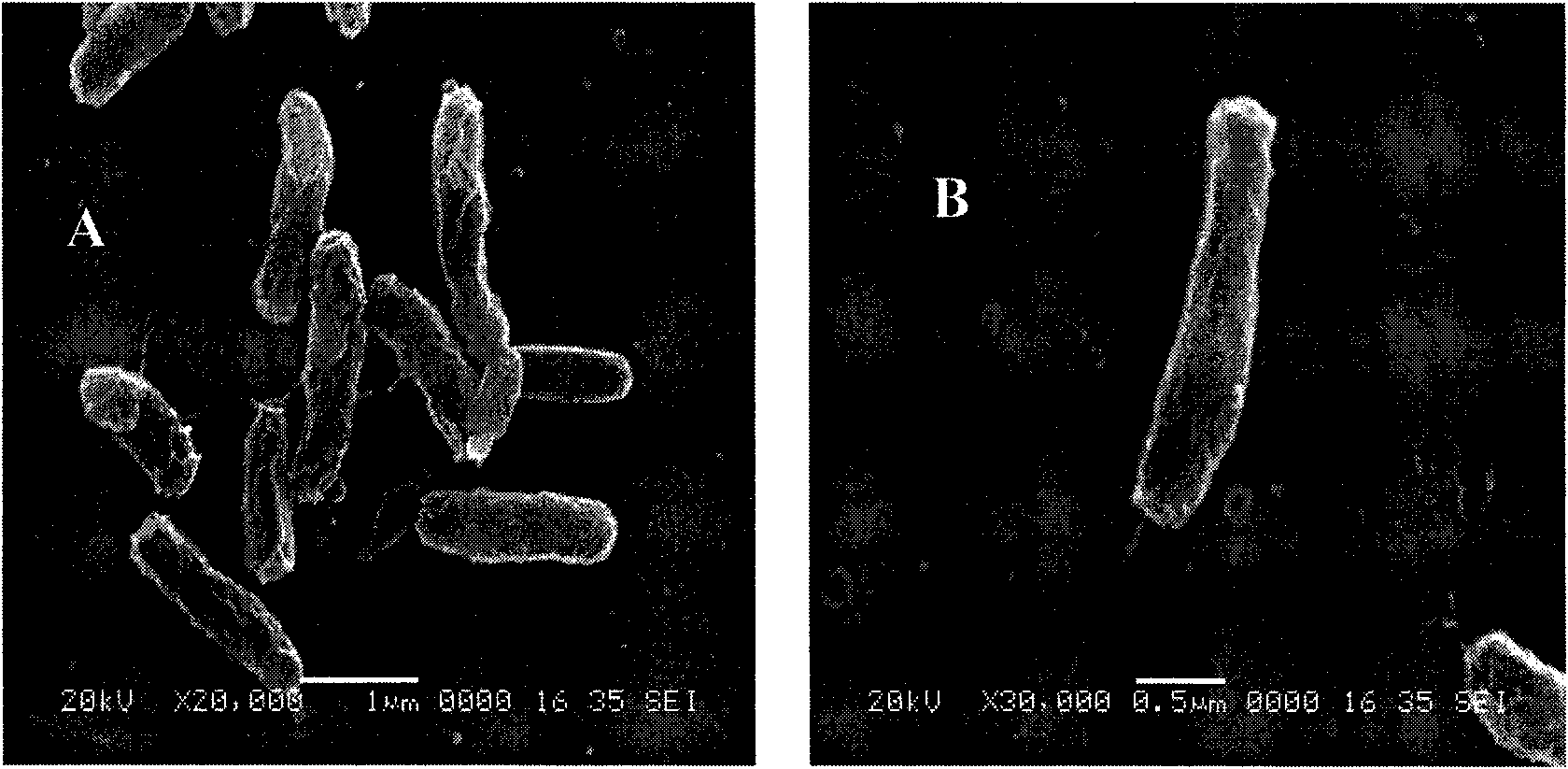

[0016] Take a little drop of the bacteria liquid on the glass slide, allow the bacteria to attach for 15 minutes, put it in a 2.5% glutaraldehyde solution and fix for 1 hour, dehydration with an alcohol gradient of 30% to 70%, replace with isoamyl acetate for 30 minutes, and dry at the critical point , Ion sputtering, scanning electron microscope observation and taking pictures, see attached figure 1 .

[0017] 1. Morphological characteristics

[0018] (1) Colony morphology characteristics: the liquid medium with chromium-reducing bacteria is inoculated into a solid medium containing 250mg / L of hexavalent chromium by the streaking plate method, and the plate is placed upside down in a 30°C constant temperature incubator. After 3 to 4 days, observe the morphology of the colony. On the plate with Cr(VI), the colony is blue-gray, round, with neat edges, and a protrusion in the middle. figure 1 ...

Embodiment 3

[0030] Example 3: Reduction of Cr(VI) by chromium reducing bacteria

[0031] Bacterial reduction Cr(VI) conditions: medium components: 5g / L sodium lactate, 5g / L yeast extract, 2g / L sodium chloride; adjust pH=9.5~9.8 with 5mol / L NaOH; temperature 30℃.

[0032] Use an inoculating loop to pick the purified colony into an Erlenmeyer flask filled with 100 mL sterile culture medium. Incubate at 30°C and a 150 rpm shaker for 24 hours. Then, use a sterile pipette to transfer 10 mL of the overnight growth , Inoculate into 100mL sterile culture medium with hexavalent chromium concentrations of 25, 50, 100, 150, 200, 300, 400 and 500 mg / L (with K 2 Cr 2 O 7 Solution as the source), incubate at 30°C, 150rpm, and shaker for 72h. During this period, at 0, 6, 12, 24, 36, 48, 60 and 72h after incubation, sample with a sterile syringe, centrifuge, and supernatant Carry out the determination of residual hexavalent chromium, the results of the determination of Cr(VI) in each period are as attached F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com