Optical material and optical element

A technology of optical materials and polymers, applied in the field of optical materials and optical components, can solve problems such as optical materials that have not yet found universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0036] The first optical material according to the present invention includes a polymer of a mixture containing at least a sulfur-containing compound, a fluorene compound, and an energy polymerization initiator.

[0037] (sulfur compounds)

[0038] The sulfur-containing compound included in the first optical material according to the present invention is a group containing at least one group selected from the group consisting of a sulfide group, a sulfone group, a sulfoxide group, a thiol group (mercapto group), and a thioester group in the molecule. compound of. In particular, in order to obtain a resin curable by energy such as light or heat, the compound preferably contains a polymerizable functional group such as an acrylic group, vinyl group or epoxy group.

[0039] Specific examples of sulfur-containing compounds include bis(4-vinylthiophenyl)sulfide, bis(4-methacryloylthiophenyl)sulfide, p-bis[β-(meth)acryloyloxy Ethylthio]xylylene, 4,4'-bis[β-(meth)acryloyloxyethylth...

Embodiment 1

[0061] Bis(4-vinylthiophenyl)sulfide (MPV) as a sulfur compound and represented by chemical formula (1) and having The fluorene compounds of the fluorene skeleton are mixed compatibly. A photoradical polymerization initiator: 2-hydroxy-2-methyl-1-phenyl-propan-1-one was added at 3% by weight to each of the resin component mixtures to obtain an optical material 11 (weight ratio of 1:1), optical material 12 (weight ratio is 1.5:1), optical material 13 (weight ratio is 2:1) and optical material 14 (weight ratio is 2.5:1), they are only made of the resin in the present invention become.

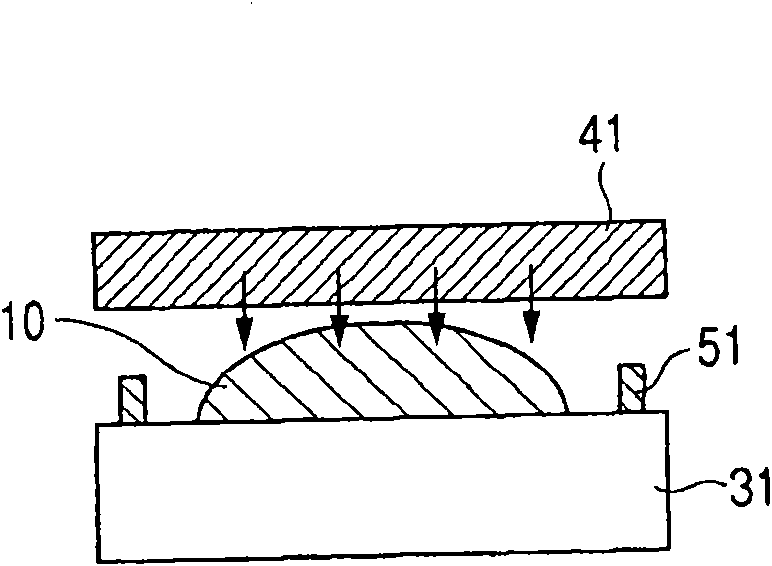

[0062] Second, pass Figures 2A-2D The fabrication steps shown in 11-14 yield molded parts from optical materials. Such as Figures 2A-2D As shown in , each of the optical materials 11-14 was clamped and fixed between the flat-shaped mold 31 and the glass substrate 41 using a spacer 51 (1 mm thick). Then, ultraviolet light 71 (total irradiation dose: 10 J) was emitted from above the glass su...

Embodiment approach 2

[0065] The second optical material according to the present invention includes a mixture containing at least a sulfur-containing compound, a fluorene compound, a polymerization initiator, and metal oxide fine particles. It should be noted that the sulfur-containing compound, fluorene compound and polymerization initiator are the same as in Embodiment 1.

[0066] (fine metal oxide particles)

[0067] Specific examples of the metal oxide fine particles included in the second optical material according to the present invention may include titanium oxide, niobium oxide, tantalum oxide, and tungsten oxide. Specifically, using TiO 2 , NbO, Nb 2 o 5 、 Ta 2 o 5 or WO 3 . The metal oxide fine particles may be composite oxide fine particles with Si, Ti, Sn, Zr or Al, if desired. In the following description, "metal oxide fine particles" are also referred to as "fine particles".

[0068] The average particle diameter of the metal oxide fine particles is preferably a particle dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com